A perovskite solar cell based on pva modified hole transport layer

A hole transport layer and solar cell technology, applied in the field of solar cells, can solve the problems of restricting visible light absorption and current density, and achieve the effects of high photoelectric conversion efficiency, low cost, and improved surface wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

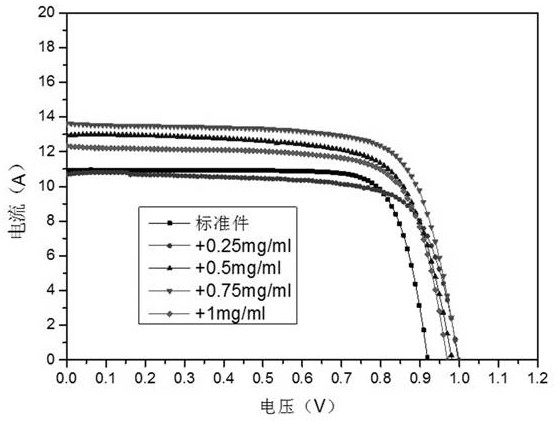

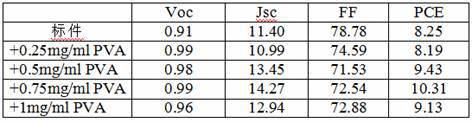

Embodiment 1

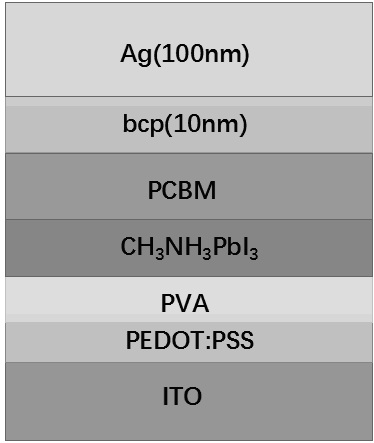

[0024] according to figure 1 The solar cell structure schematic diagram is used to prepare the device, and the preparation method includes:

[0025] Wash commercial ITO twice with washing solution, deionized water, acetone, and ethanol for 15 minutes each, then blow dry with nitrogen, and treat with plasma for 4 minutes;

[0026] The cleaned and plasma-treated ITO glass was spin-coated on a homogenizer at a speed of 4000 rpm for 30 seconds to prepare a hole transport layer PEDOT:PSS and annealed on a hot stage at 130°C for 20 minutes;

[0027] Dissolve PVA in deionized water at a concentration of 0.25mg / ml, heat and stir at 95°C to fully disperse PVA, spin-coat at 900rpm for 15s, and spin-coat at 4000rpm for 25s in two steps of continuous spin-coating, at 100°C in a glove box environment Anneal for 10 minutes;

[0028] Make lead iodide and methylamine lead iodide into a solution with a concentration of 1.4mmol / ml according to the molar ratio of 1:1, in which the solvent is a...

Embodiment 2

[0032] according to figure 1 The solar cell structure schematic diagram is used to prepare the device, and the preparation method includes:

[0033] Wash commercial ITO twice with washing solution, deionized water, acetone, and ethanol for 15 minutes each, then blow dry with nitrogen, and treat with plasma for 4 minutes;

[0034] The cleaned and plasma-treated ITO glass was spin-coated on a homogenizer at a speed of 4000 rpm for 30 seconds to prepare a hole transport layer PEDOT:PSS and annealed on a hot stage at 130°C for 20 minutes;

[0035]Dissolve PVA in deionized water at a concentration of 0.5mg / ml, heat and stir at 95°C to fully disperse PVA, spin-coat at 900rpm for 15s, and spin-coat at 4000rpm for 25s in two steps of continuous spin-coating, at 100°C in a glove box environment Anneal for 10 minutes;

[0036] Make lead iodide and methylamine lead iodide into a solution with a concentration of 1.4mmol / ml according to the molar ratio of 1:1, in which the solvent is a m...

Embodiment 3

[0040] according to figure 1 The solar cell structure schematic diagram is used to prepare the device, and the preparation method includes:

[0041] Wash commercial ITO twice with washing solution, deionized water, acetone, and ethanol for 15 minutes each, then blow dry with nitrogen, and treat with plasma for 4 minutes;

[0042] The cleaned and plasma-treated ITO glass was spin-coated on a homogenizer at a speed of 4000 rpm for 30 seconds to prepare a hole transport layer PEDOT:PSS and annealed on a hot stage at 130°C for 20 minutes;

[0043] Dissolve PVA in deionized water at a concentration of 0.75mg / ml, heat and stir at 95°C to fully disperse PVA, spin-coat at 900rpm for 15s, and spin-coat at 4000rpm for 25s in two steps of continuous spin-coating, at 100°C in a glove box environment Anneal for 10 minutes;

[0044] Make lead iodide and methylamine lead iodide into a solution with a concentration of 1.4mmol / ml according to the molar ratio of 1:1, in which the solvent is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com