Oral antimicrobial composition as well as preparation method and application thereof

A composition and oral technology, applied in the field of oral care, can solve the problems of ineffective adhesion, low drug utilization rate, inability to obtain ideal effects, etc., and achieve the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

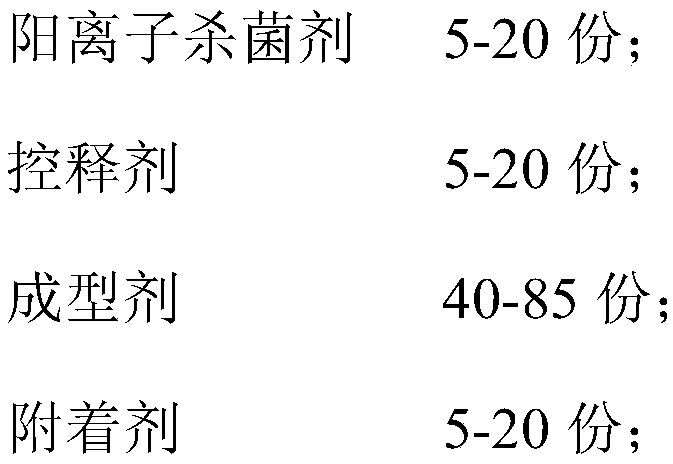

Method used

Image

Examples

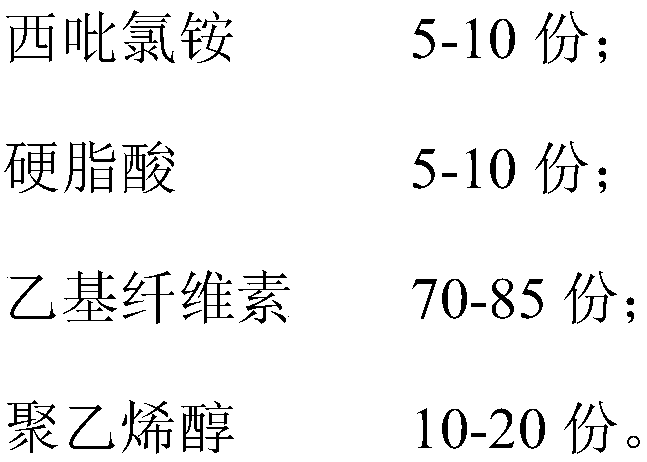

Embodiment 1

[0039] A preparation method of an oral antibacterial composition, comprising the following processing steps:

[0040] Add 5 parts of cetylpyridinium chloride, 85 parts of ethyl cellulose, 5 parts of stearic acid, and 5 parts of polyvinyl alcohol (molecular weight is 75000) into the beaker, and add 75% ethanol solution, heat at 40 ° C and stir until mixed Evenly, the sample stock solution with a total mass fraction of each raw material of 10% was obtained, and passed through a spray dryer, and the parameters were set as follows: sample injection rate 10mL / min, air volume 60m 3 / h, atomization air pressure 0.1Mpa, air inlet temperature 140°C, needle pass frequency 60S, and powder particles with a particle size of 5 μm were prepared.

Embodiment 2

[0042] A preparation method of an oral antibacterial composition, comprising the following processing steps:

[0043] Add 5 parts of cetylpyridinium chloride, 70 parts of ethyl cellulose, 5 parts of stearic acid, 20 parts of polyvinyl alcohol (molecular weight is 75000) into the beaker, and add 75% ethanol solution, heat at 40 ° C and stir until mixed Evenly, the sample stock solution with a total mass fraction of each raw material of 10% was obtained, and passed through a spray dryer, and the parameters were set as follows: sample injection rate 10mL / min, air volume 60m 3 / h, atomization air pressure 0.1Mpa, air inlet temperature 140°C, needle pass frequency 60S, and powder particles with a particle size of 5 μm were prepared.

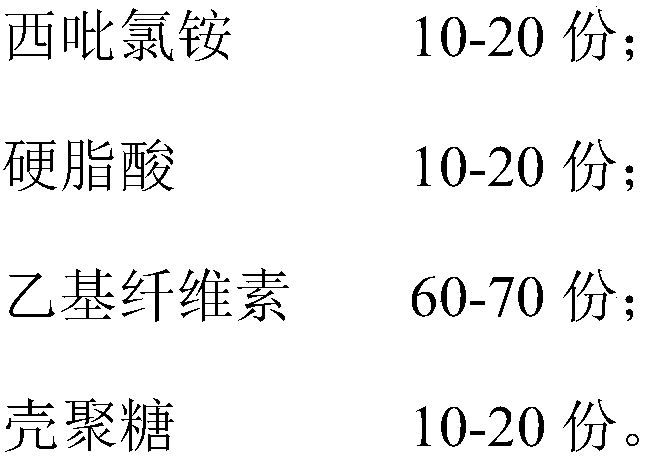

Embodiment 3

[0045] A preparation method of an oral antibacterial composition, comprising the following processing steps:

[0046] Add 10 parts of cetylpyridinium chloride, 70 parts of ethyl cellulose, 10 parts of stearic acid, 10 parts of chitosan (molecular weight is 300000) into the beaker, and add 75% ethanol solution, heat at 40 ℃ and stir until mixed Evenly, the sample stock solution with a total mass fraction of each raw material of 10% was obtained, and passed through a spray dryer, and the parameters were set as follows: sample injection rate 10mL / min, air volume 60m 3 / h, atomization air pressure 0.1Mpa, air inlet temperature 140°C, needle pass frequency 60S, and powder particles with a particle size of 5 μm were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com