Preparation method of salt-tolerant flexible anti-seepage material

A flexible anti-seepage material and salt-resistant technology, which is applied in coatings and other directions, can solve the problems of poor salt resistance of anti-seepage materials, affecting application life, and migration of plasticizers, so as to increase the softening point, reduce the acid The effect of lowering the transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

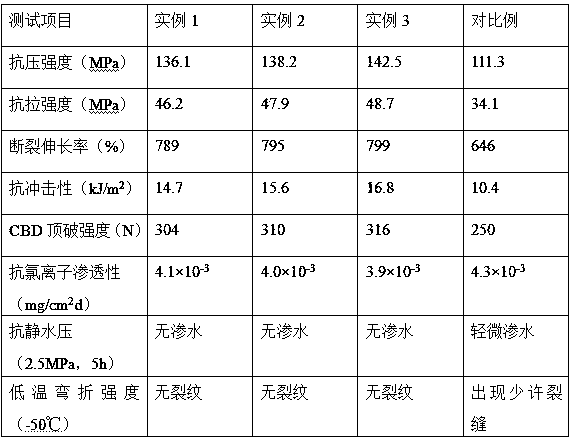

Examples

Embodiment Construction

[0025] In parts by weight, add 80-90 parts of hexamethylene diisocyanate, 30-40 parts of polyether diol, and 20-30 parts of rosin into the three-necked flask, heat up to 80-85°C, keep the temperature for 2-3 hours, and then cool down to 50-60°C, add 10-15 parts of dimethylolpropionic acid, 20-30 parts of glycerin and 20-25 parts of maleic anhydride to the three-necked flask in sequence, and dissolve 3-5 parts of dibutyltin dilaurate in 35 After ~40 parts of acetone, use a constant pressure dropping funnel to drop it into a three-necked flask at a dropping rate of 2~3mL / min, raise the temperature while adding it, control the heating rate at 3~5°C / min, and raise the temperature to 80~82 °C, continue to react for 3-4 hours to obtain anti-seepage slurry; in parts by weight, take 60-70 parts of ethylene-vinyl acetate copolymer, 20-25 parts of expandable graphite, 10-15 parts of EPS foam particles, Put 8-10 parts of vinyl ester resin into a reaction kettle, heat up to 230-250°C, kne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com