Cathode composite material of fast ion modified silicate lithium battery, and preparation method thereof

A composite material and ion modification technology, which is applied in the field of fast ion modified silicate lithium battery positive electrode composite materials and its preparation, to avoid direct contact, prevent sintering and agglomeration, and improve contact conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

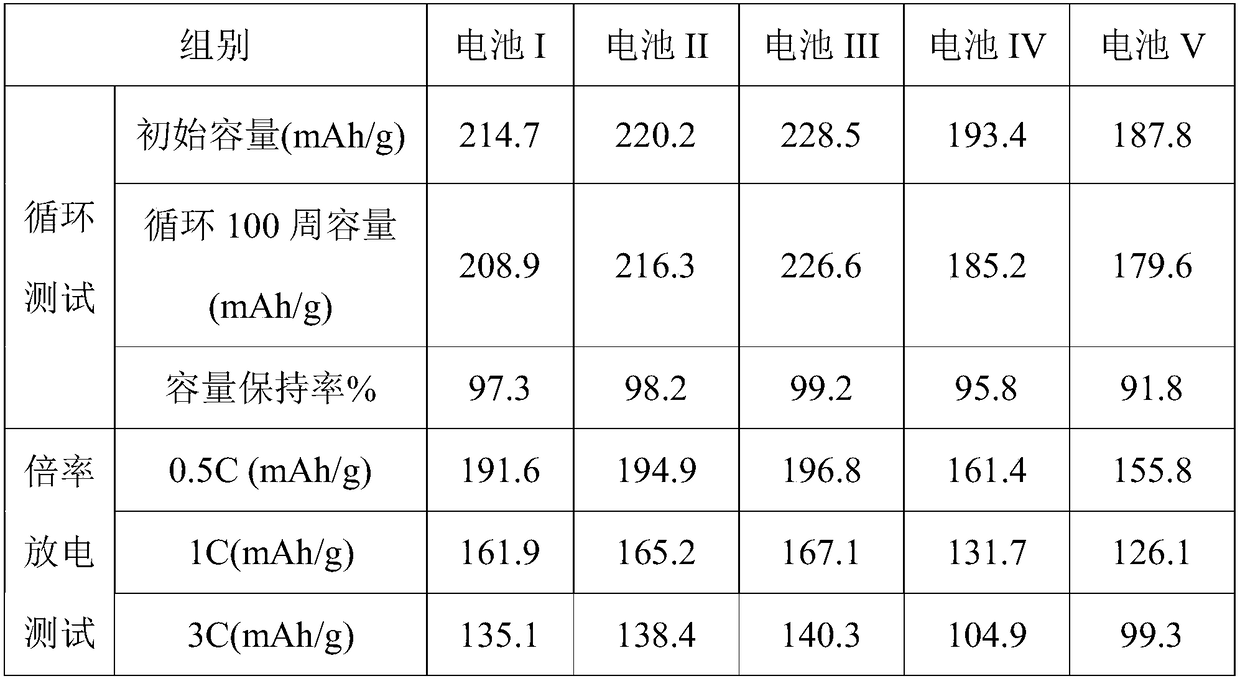

Examples

Embodiment 1

[0020] Example 1 Preparation of Fast Ion Modified Silicate Lithium Battery Positive Electrode Composite Material I

[0021] Step 1. Lithium acetate, manganese acetate, iron acetate, tetraethyl orthosilicate in molar ratio Li: Ca: Fe: Mn: SiO 4 2- =2:0.4:0.6:1 After accurate weighing, put it into the reactor, and then add the catalyst, the catalyst is an acetic acid-ethanol mixture with a mass ratio of acetic acid and ethanol of 1:20, fully stir evenly, and in a sealed state React at 100°C for 18-36 hours to obtain a gel;

[0022] Step 2. Take out the gel obtained in step 1, dry it and mix it with glucose. The mass ratio of the fast ion precursor to glucose is 1:0.01. Then, the mixture is ball milled in a planetary ball mill. The ball milling medium is deionized water. Mix at a speed of 400r / min for 3 hours, prepare the mixture into a homogenate with a mass concentration of 10%wt., pump the homogenate into a spray drying tower for granulation, the spray gas is air, the inlet ...

Embodiment 2

[0024] Example 2 Preparation of Fast Ion Modified Silicate Lithium Battery Positive Electrode Composite Material II

[0025] Step 1. Lithium acetate, manganese acetate, iron acetate, tetraethyl orthosilicate in molar ratio Li: Ca: Fe: Mn: SiO 4 2- =2:0.8:0.2:1 After accurate weighing, put it into the reactor, and then add the catalyst, the catalyst is an acetic acid-ethanol mixture with a mass ratio of acetic acid and ethanol of 1:30, fully stir evenly, and in a sealed state React at 150°C for 18-36 hours to obtain a gel;

[0026] Step 2. Take out the gel obtained in step 1, dry it and mix it with sucrose. The mass ratio of fast ion precursor to sucrose is 1:0.2, and then ball mill the mixture in a planetary ball mill. The ball milling medium is deionized water. Mix at a speed of 400r / min for 3 hours, prepare the mixture into a homogenate with a mass concentration of 25%wt., pump the homogenate into a spray drying tower for granulation, the spray gas is nitrogen, the inlet t...

Embodiment 3

[0028] Example 3 Preparation of Fast Ion Modified Silicate Lithium Battery Positive Electrode Composite Material III

[0029] Step 1. Lithium acetate, manganese acetate, iron acetate, tetraethyl orthosilicate in molar ratio Li: Ca: Fe: Mn: SiO 4 2- =2:0.5:0.5:1 After accurate weighing, put it into the reactor, and then add the catalyst, the catalyst is an acetic acid-ethanol mixture with a mass ratio of acetic acid and ethanol of 1:25, fully stir evenly, and in a sealed state React at 120°C for 18-36 hours to obtain a gel;

[0030] Step 2. Take out the gel obtained in step 1, dry it and mix it with polyethylene glycol. The mass ratio of fast ion precursor to polyethylene glycol is 1:0.1, and then ball mill the mixture in a planetary ball mill, and the ball milling medium It is deionized water, mixed for 3 hours at a speed of 400r / min, the mixture is prepared into a homogenate with a mass concentration of 15%wt., and the homogenate is pumped into a spray drying tower for gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com