Preparation method for hollow micro-structure Co3S4@MoS2 of lithium ion battery negative electrode by MOF template

A lithium ion battery, hollow micro technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of volume change, large dissolved polysulfide, unsatisfactory cycle stability, and slow Li ion diffusion. , to achieve the effect of solving capacity attenuation, high success rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

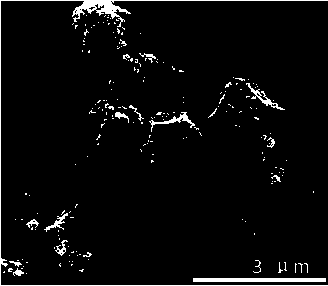

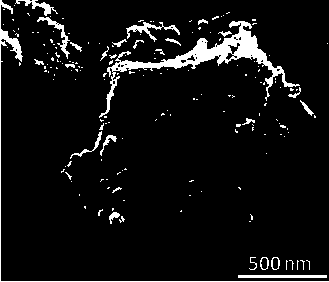

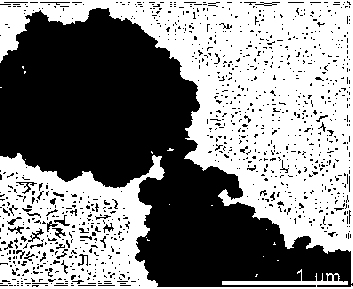

Image

Examples

Embodiment 1

[0044] Cobalt nitrate hexahydrate (8.7364 g) was added to 300 mL of methanol respectively to form a solution and shaken for 3 minutes. 2-Methylimidazole (9.8430 g) was added to 100 mL of methanol to form a solution and shaken for 3 minutes. The two solutions were then mixed and treated with ultrasound (40000 Hz) for 10 minutes. The mixed solution was left at room temperature for 12 hours to obtain precipitation. Next, the precipitate was collected, separated by centrifugation, washed 5 times with methanol, and dried overnight at 80 °C to obtain the ZIF-67 precursor template.

[0045] Add 400 mg ZIF-67 precursor template and 200 mg dopamine into 500 mL Tris buffer solution (pH = 8, 10 mM) and stir for 5 h. The precipitate was collected by centrifugation, washed several times with deionized water and ethanol, and dried at 70 °C to obtain ZIF-67@PDA nanocubes. Finally, the ZIF-67@PDA nanocubes were annealed at 600 °C for 2 hours under Ar conditions, and the Co 3 o 4 @C sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com