Reducing titanium dioxide photocatalyst as well as preparation method and application thereof

A titanium dioxide and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the secondary pollution of adsorbent saturation and desorption, unsatisfactory treatment effect of volatile organic compounds, limited light Problems such as the application and promotion of catalytic technology, to achieve the effect of low price, simple preparation method and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

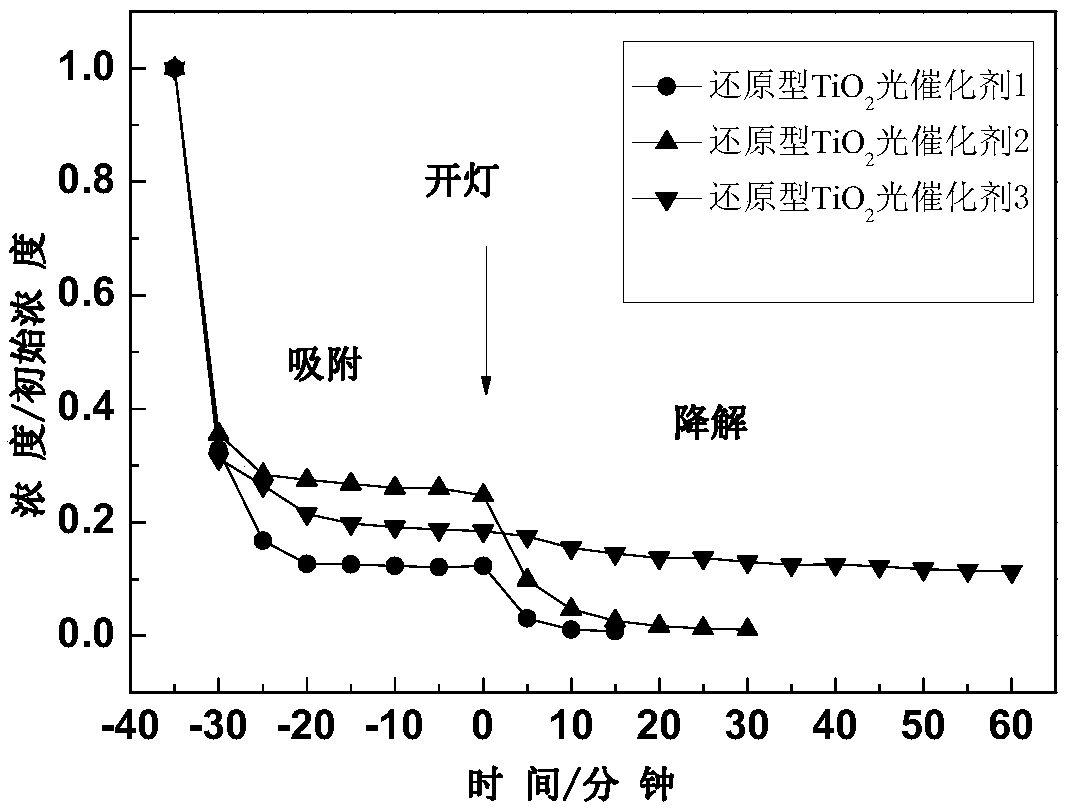

Embodiment 1

[0027] 1. Add TiO 2 Mix it with aluminum at a mass ratio of 1:0.1, put it into a tube furnace filled with nitrogen, and react at 1000°C for 2 hours to obtain a powder sample;

[0028] 2. Rinse the powder sample obtained in step 1 with 50 mL of 0.1 mol / L hydrochloric acid once and then dry it at 30°C to obtain reduced TiO 2 Photocatalyst 1.

Embodiment 2

[0030] 1. Add TiO 2 Mix it with magnesium at a mass ratio of 1:10, put it into a tube furnace filled with hydrogen, and react at 100°C for 72 hours to obtain a powder sample;

[0031] 2. Rinse the powder sample obtained in step 1 with 500mL of 1mol / L sulfuric acid for 5 times and then dry it at 100°C to obtain reduced TiO 2 Photocatalyst 2.

Embodiment 3

[0033] 1. Add TiO 2 Mix it with zinc at a mass ratio of 1:0.2, put it into a tube furnace filled with carbon dioxide, and react at 400°C for 10 hours to obtain a powder sample;

[0034] 2. Rinse the powder sample obtained in step 1 with 200mL of 0.5mol / L nitric acid for 3 times and then dry it at 600°C to obtain reduced TiO 2 Photocatalyst3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com