A kind of two-dimensional titanium dioxide crystal form, sol and preparation method thereof

A technology of titanium dioxide and sol, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as limiting catalytic activity, and achieve strong catalytic effect, strong catalytic activity, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

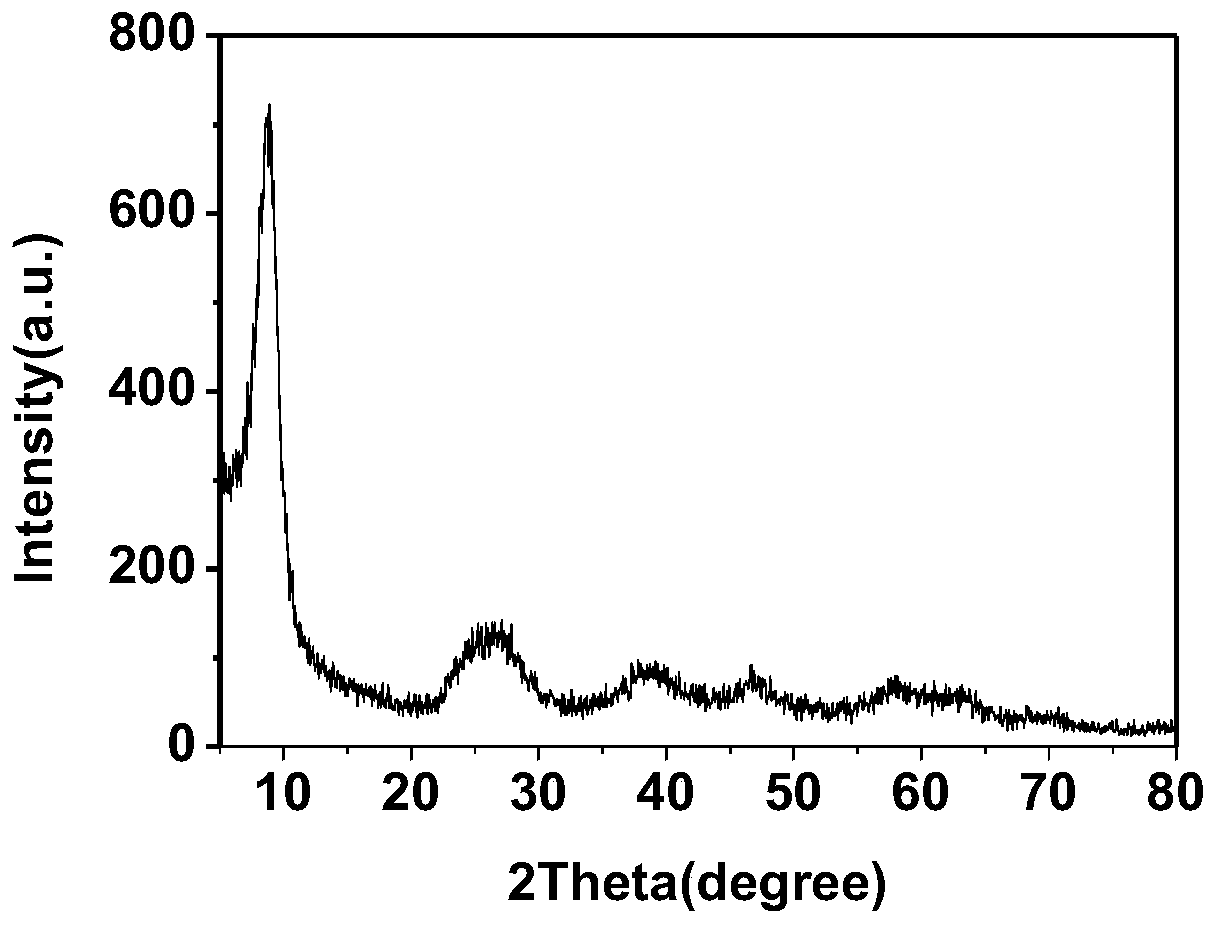

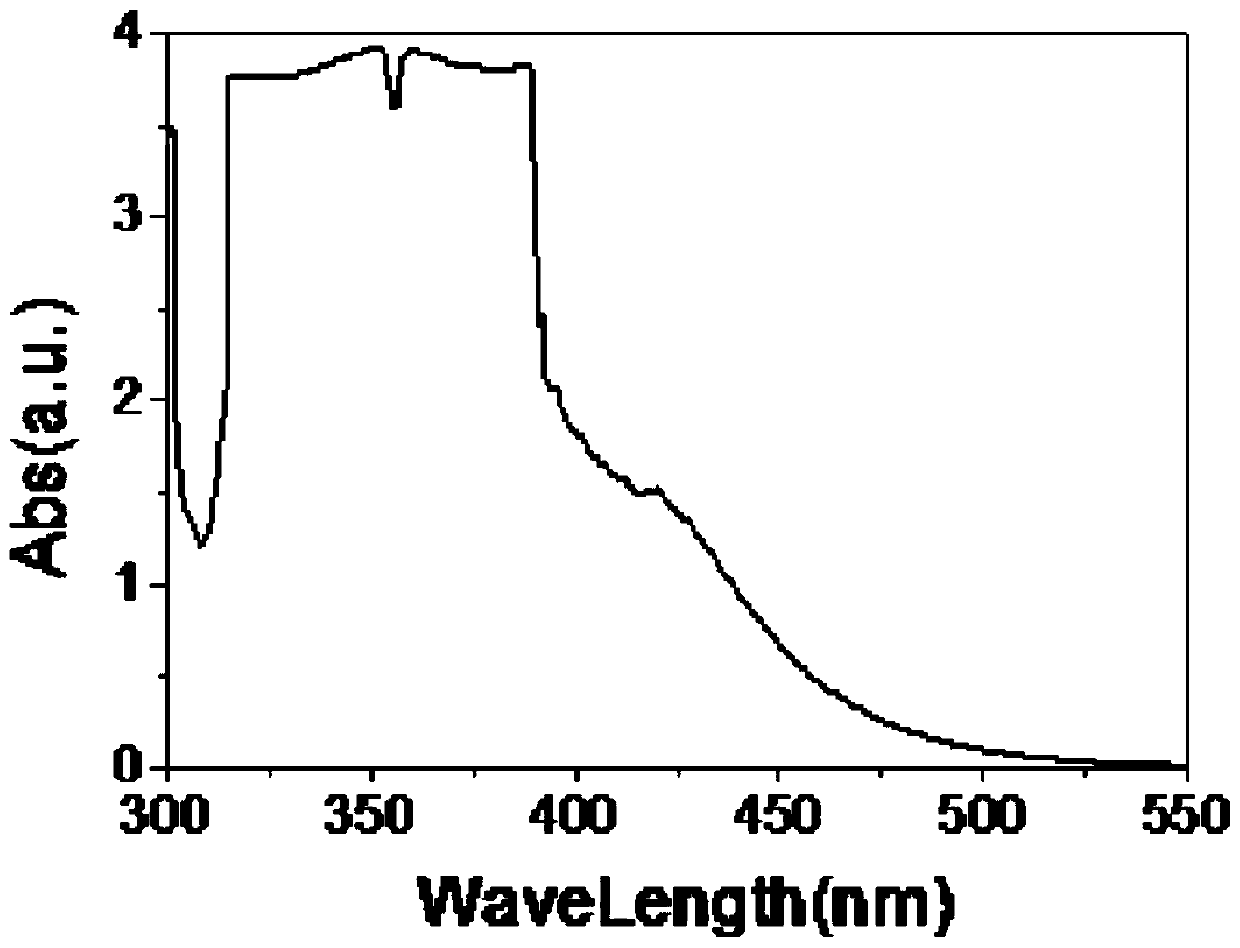

[0032] Example 1: Preparation of a two-dimensional titania sol

[0033] At a temperature of 0°C, take 2ml of titanium tetrachloride and add it to a mixture composed of 7ml of absolute ethanol, 0.6ml of polyvinylpyrrolidone and 20ml of deionized water, start stirring, and set the rotation speed to 300r / min for stirring. After 20 minutes, a mixed solution was obtained; then, 11 ml of an ammonia solution with a mass concentration of 26% was added dropwise to the mixed solution to adjust the pH of the mixed solution to 7.0, and a white precipitate was obtained. Centrifuge the white precipitate, set the speed of the centrifuge to 12000r / min, and centrifuge for 7 minutes. After the centrifugation is over, wash it with 80ml of deionized water for 9 times until it does not contain chloride ions; A mixture of 20ml of 30% hydrogen peroxide and sodium peroxide and 120ml of deionized water, then placed in a temperature of 110°C for condensing and refluxing for 3.5h to obtain a transparent...

Embodiment 2

[0044] Embodiment 2 A kind of preparation method of two-dimensional titanium dioxide

[0045] At a temperature of -1°C, take 1ml of titanium tetrachloride and add it to a mixture composed of 12ml of absolute ethanol, 1ml of polyvinylpyrrolidone and 30ml of deionized water, start stirring, set the speed at 500r / min for stirring, and stir After 10 minutes, a mixed solution was obtained; then, 3 ml of ammonia solution with a mass concentration of 28% was added dropwise to the mixed solution to adjust the pH of the mixed solution to 6.5, and a white precipitate was obtained. Centrifuge the white precipitate, set the speed of the centrifuge to 16000r / min, and centrifuge for 3min. After the centrifugation is over, wash it with 120ml of deionized water for 8 times until it does not contain chloride ions; The mixture 16ml of 30% hydrogen peroxide and sodium peroxide and 100ml of deionized water are then placed in a temperature of 120°C and condensed and refluxed for 3h to obtain a tra...

Embodiment 3

[0047] Embodiment 3: A kind of preparation method of two-dimensional titanium dioxide

[0048] At a temperature of 1°C, take 4ml of titanium tetrachloride and add it to a mixture composed of 12ml of absolute ethanol, 0.1ml of polyvinylpyrrolidone and 15ml of deionized water, start stirring, and set the rotation speed to 200r / min for stirring. After 40 minutes, a mixed solution was obtained; then, 12 ml of an ammonia solution with a mass concentration of 25% was added dropwise to the mixed solution to adjust the pH of the mixed solution to 6.5, and a white precipitate was obtained. Centrifuge the white precipitate, set the speed of the centrifuge to 4000r / min, and centrifuge for 10 minutes. After the centrifugation, wash 10 times with 50ml of deionized water until it does not contain chloride ions; The mixture 16ml of 30% hydrogen peroxide and sodium peroxide and 150ml of deionized water are then placed in a temperature of 90°C and condensed and refluxed for 4h to obtain a tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com