Grouting material for prestress pore duct

A pore grouting and prestressing technology, which is applied in the field of building materials, can solve the problems of easy bleeding and poor fluidity of the grouting slurry, and achieve the effects of reducing bleeding, reducing contact angle and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

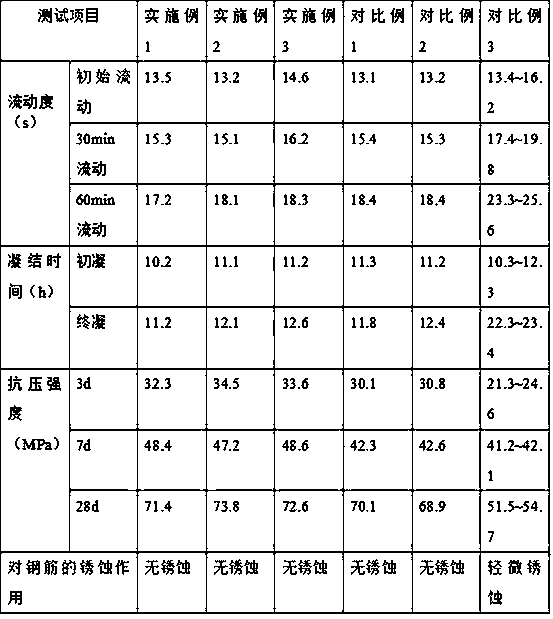

Examples

preparation example Construction

[0030] A preparation method for a biological polysaccharide complex, comprising the steps of:

[0031] (1) Take Bacillus licheniformis powder and mix it with sterile water at a mass ratio of 1:20~30 to obtain a bacterial solution. Take the bacterial solution and inoculate it into the activation medium at a 6% inoculation amount. Shake culture at 280r / min for 10~12h to obtain activated culture solution, take the activated culture solution and centrifuge at 3000~4000r / min for 10~15min, take the supernatant, add 2~4 times the weight of the supernatant to mix, shake for 10 Resuspend for ~20min to obtain a suspension, take the suspension and add agar and deionized water at a mass ratio of 10:2~3:100 to mix, stir at 350~500r / min for 30~50min to obtain a base solution, take the base solution Add CaCl with a concentration of 0.1mol / L of 20~35% of the mass of the base liquid 2 Mix the solutions, refrigerate at 1~4°C for 1~2 days, obtain the feed liquid, and set aside;

[0032] (2) Ta...

Embodiment 1

[0040] Plasticizer: Mix dibutyl phthalate and epoxy soybean oil at a mass ratio of 4:1 to obtain a plasticizer.

[0041] Defoamer: Mix polydimethylsiloxane and silicon dioxide at a mass ratio of 5:1 to obtain a defoamer.

[0042] Water reducer: polycarboxylate water reducer model XBW-10.

[0043] Preservative: Butyl paraben.

[0044] Expansion agent: mix alum stone, magnesium oxide and aggregate according to the mass ratio of 4:1:2 to obtain the expansion agent.

[0045] Biogas slurry pretreatment: in a water bath at 40°C, mix biogas slurry, zeolite, and clay at a mass ratio of 5:1:0.1, stir and mix at 350r / min, leave to soak for 10 hours, filter, take the filtrate and add mature vinegar with a mass of 8% of the filtrate 1. Mix evenly with water twice the quality of the filtrate to obtain the pretreated biogas slurry.

[0046] Stearic acid compound liquid: at 30°C, take stearic acid, 4-dimethylaminopyridine, and dimethyl sulfoxide in a mass ratio of 5:1:8 and stir and mix t...

Embodiment 2

[0058] Plasticizer: Mix dibutyl phthalate and epoxy soybean oil at a mass ratio of 4:2 to obtain a plasticizer.

[0059] Defoamer: Mix polydimethylsiloxane and silicon dioxide at a mass ratio of 5:2 to obtain a defoamer.

[0060] Water reducer: polycarboxylate water reducer model JW-8.

[0061] Preservative: ethyl paraben.

[0062] Expansion agent: Mix alum stone, magnesium oxide and aggregate according to the mass ratio of 4:1:4 to obtain the expansion agent.

[0063] Biogas slurry pretreatment: in a water bath at 55°C, mix biogas slurry, zeolite, and clay according to the mass ratio of 5:2:0.1, stir and mix at 500r / min, let stand and soak for 12 hours, filter, take the filtrate and add mature vinegar with a mass of 15% of the filtrate 1. Mix evenly with water 5 times the mass of the filtrate to obtain the pretreated biogas slurry.

[0064] Stearic acid compound solution: at 45°C, take stearic acid, 4-dimethylaminopyridine, and dimethyl sulfoxide in a mass ratio of 5:1:12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com