Method for preparing pravastatin-loaded vascular tissue engineering scaffold material by electrospinning

An electrospinning and vascular tissue technology, applied in the field of fibrous artificial vascular materials, can solve the problems of non-degradable, non-degradable, and only 1 to 7 days, and achieve the effects of easy regulation, simple method, and prevention of recurrence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of scaffold materials for vascular tissue engineering

[0024] (1) Add poly(3-hydroxybutyrate-3-hydroxyhexanoate) into dichloromethane, heat and magnetically stir in a water bath at 30°C for 24 hours, and prepare a polyhydroxyalkanoate solution with a mass concentration of 7%, statically Remove air bubbles after placing;

[0025] (2) Add pravastatin sodium in acetic acid, stir magnetically at 25° C., and make a pravastatin sodium solution with a concentration of 20 mg / mL;

[0026] (3) According to the volume ratio of polyhydroxyalkanoate solution: pravastatin sodium solution=1:1, under the condition of mixing slowly while stirring, the polyhydroxyalkanoate solution and pravastatin sodium solution are mixed uniformly, Obtain an electrospinning solution;

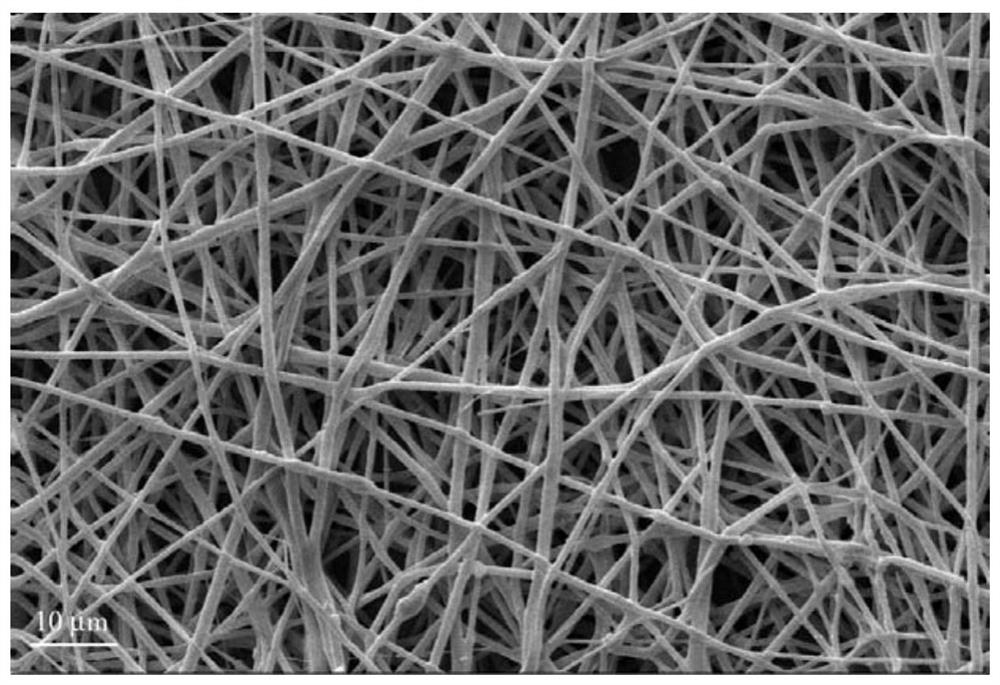

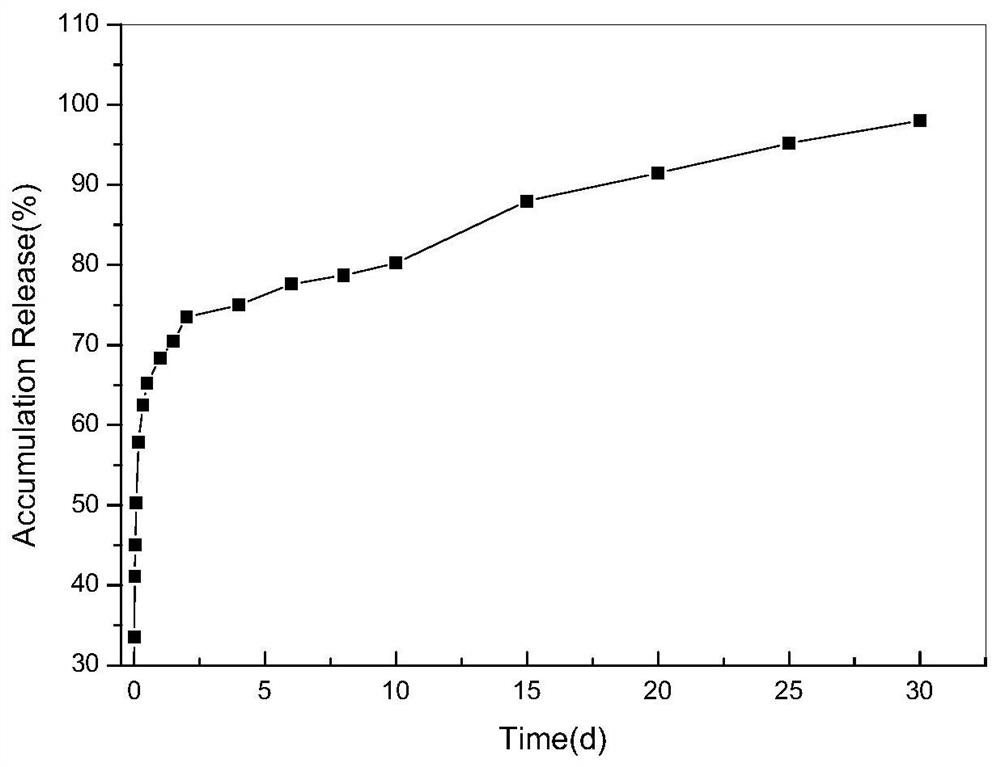

[0027] (4) Put the electrospinning solution obtained in step (3) into an electrospinning device for electrospinning to obtain micro-nano fibers, and dry them in vacuum at 60° C. for 24 hours to obtain t...

Embodiment 2

[0031] 1. Preparation of scaffold materials for vascular tissue engineering

[0032] (1) Add poly(3-hydroxybutyrate-3-hydroxyvalerate) into a mixed solvent of chloroform and DMF, heat and magnetically stir in a water bath at 50°C for 24 hours, and prepare polyhydroxyalkane with a mass concentration of 30%. Ester solution, remove bubbles after leaving standstill; Wherein the mixed volume ratio of chloroform and DMF in the mixed solvent is 8: 2;

[0033] (2) Add pravastatin sodium to isopropanol, stir magnetically at 40° C., and prepare a pravastatin sodium solution with a concentration of 300 mg / mL;

[0034] (3) According to the volume ratio of polyhydroxyalkanoate solution: pravastatin sodium solution=8:1, under the condition of mixing slowly while stirring, the polyhydroxyalkanoate solution and pravastatin sodium solution are mixed uniformly, Obtain an electrospinning solution;

[0035] (4) Put the electrospinning solution obtained in step (3) into an electrospinning device...

Embodiment 3

[0039] 1. Preparation of scaffold materials for vascular tissue engineering

[0040] (1) Add poly(3-hydroxybutyrate-4-hydroxybutyrate) into chloroform, heat and magnetically stir in a water bath at 40°C for 12h, and prepare a polyhydroxyalkanoate solution with a mass concentration of 20%, statically Remove air bubbles after placing;

[0041] (2) Pravastatin sodium is added in the mixed solvent of ethanol and DMF, under 25 ℃ magnetic stirring, be made into the pravastatin sodium solution that concentration is 100mg / mL; Wherein the volume ratio of ethanol and DMF in the said mixed solvent is 1:1;

[0042] (3) According to the volume ratio of polyhydroxyalkanoate solution:pravastatin sodium solution=6:1, under the condition of mixing slowly while stirring, the polyhydroxyalkanoate solution and pravastatin sodium solution are mixed evenly, Obtain an electrospinning solution;

[0043] (4) Put the electrospinning solution obtained in step (3) into an electrospinning device for el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com