Carbon nano onion/titanium dioxide/silicon dioxide composite photocatalytic material as well as preparation method and application thereof

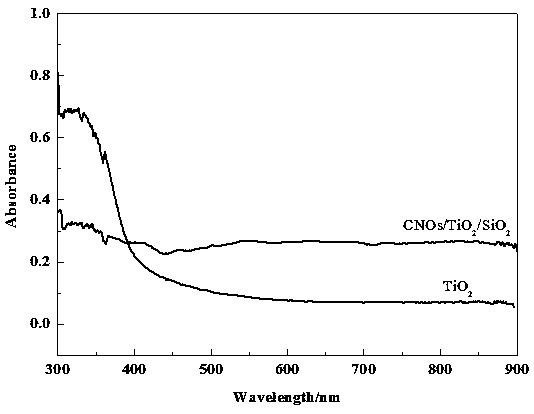

A technology of composite photocatalysis and titanium dioxide, applied in the field of photocatalytic materials, can solve the problems of short wavelength and low quantum efficiency, and achieve the effects of inhibiting separation, improving catalytic efficiency and high visible light catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

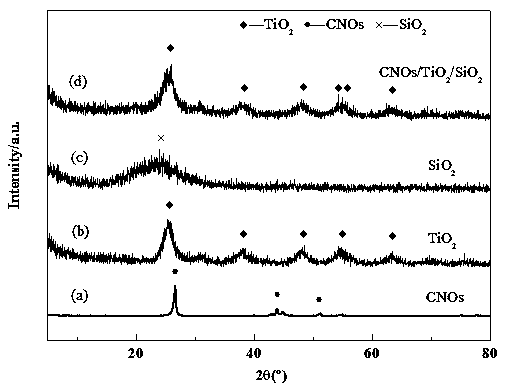

[0035] A nano-onion carbon / titanium dioxide / silica (CNOs / TiO 2 / SiO 2 ) The concrete steps of the preparation method of catalyst are as follows:

[0036] (1) Purification of CNOs

[0037] Weigh 15g of CNOs and disperse in 750mL of nitric acid solution with a mass fraction of 68%, acid-dissolve and reflux at 80°C for 2h, wash the pickled product repeatedly with distilled water until the pH is neutral, dry at 80°C, and calcined at 400°C , grinding;

[0038] (2) CNOs / TiO 2 / SiO 2 preparation of

[0039]1) Mix 6 mL of titanium tetraisopropoxide and 3 mL of isopropanol solution and stir for 1 min, weigh 0.0192 g of pickled CNOs and add to the mixed solution and stir, transfer the mixed solution to the dropping funnel, add dropwise to the In a round bottom flask of 42mL distilled water, the dropping rate was controlled at 0.3mL / min, while stirring, and the condensation system was turned on;

[0040] 2) Add 1 mL of nitric acid solution dropwise to the mixed solution in step 1)...

Embodiment 2

[0052] (1) Purification of CNOs

[0053] Weigh 15g of CNOs and disperse in 750mL nitric acid solution with a mass fraction of 68%, acid reflux treatment at 80°C for 2h, wash the pickled product with distilled water repeatedly until the pH is neutral, dry at 80°C, and dry at 400°C calcined, ground;

[0054] (2) CNOs / TiO 2 / SiO 2 preparation

[0055] 1) Mix 6 mL of titanium tetraisopropoxide and 3 mL of isopropanol solution and stir for 1 min, weigh 0.0576 g of acid-washed CNOs into the mixed solution and stir, transfer the mixed solution to the dropping funnel, add dropwise to the In a round bottom flask of 42mL distilled water, the dropping rate was controlled at 0.3mL / min, while stirring, and the condensation system was turned on;

[0056] 2) Add 1mL of nitric acid solution to the mixed solution in step 1) dropwise, the dropping rate is controlled at 0.25mL / min, heated and stirred in a water bath at 70°C, after the reaction is completed, turn on the cooling water system t...

Embodiment 3

[0064] (1) Purification of CNOs

[0065] Weigh 15g of CNOs and disperse in 750mL nitric acid solution with a mass fraction of 68%, acid reflux treatment at 80°C for 2h, wash the pickled product with distilled water repeatedly until the pH is neutral, dry at 80°C, and dry at 400°C calcined, ground;

[0066] (2) CNOs / TiO 2 / SiO 2 preparation

[0067] 1) Mix 7mL titanium tetraisopropoxide and 3mL isopropanol solution and stir for 1min, weigh 0.0192g of pickled CNOs and add to the mixed solution and stir, transfer the mixed solution to the dropping funnel, add dropwise In a round bottom flask of 42mL distilled water, the dropping rate was controlled at 0.3mL / min, while stirring, and the condensation system was turned on;

[0068] 2) Add 1 mL of nitric acid solution dropwise to the mixed solution in step 1), the rate of addition is controlled at 0.25 mL / min, heated and stirred in a water bath at 70 °C, after the reaction is completed, the cooling water system is connected to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com