Production technology for casting zinc alloy water faucet

A production process, zinc alloy technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of complex waterways, easily scratched water pipes, residual electroplating solution, etc., achieve long service life, easy to wear pipes , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Below in conjunction with specific embodiment, this case is described in further detail.

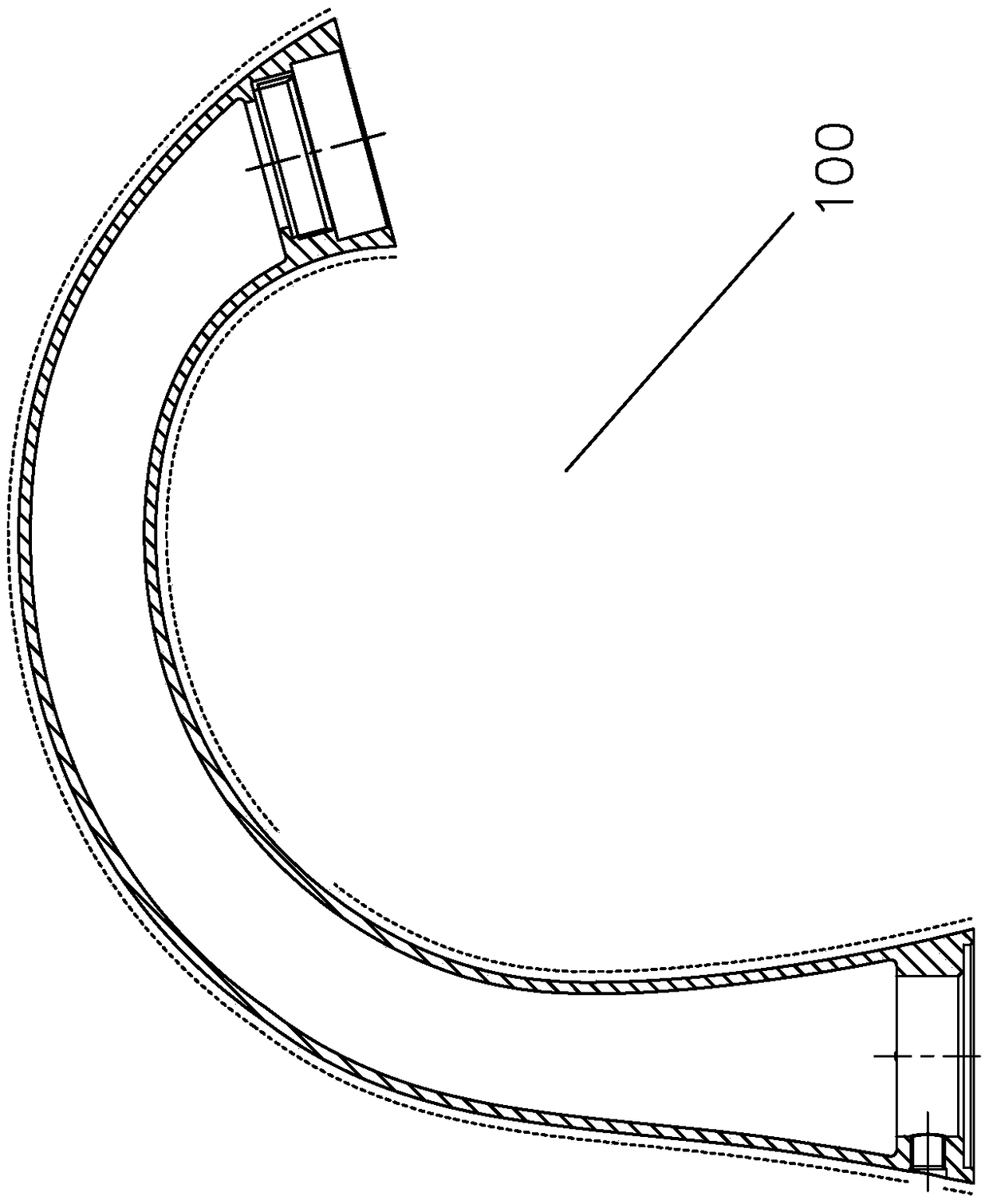

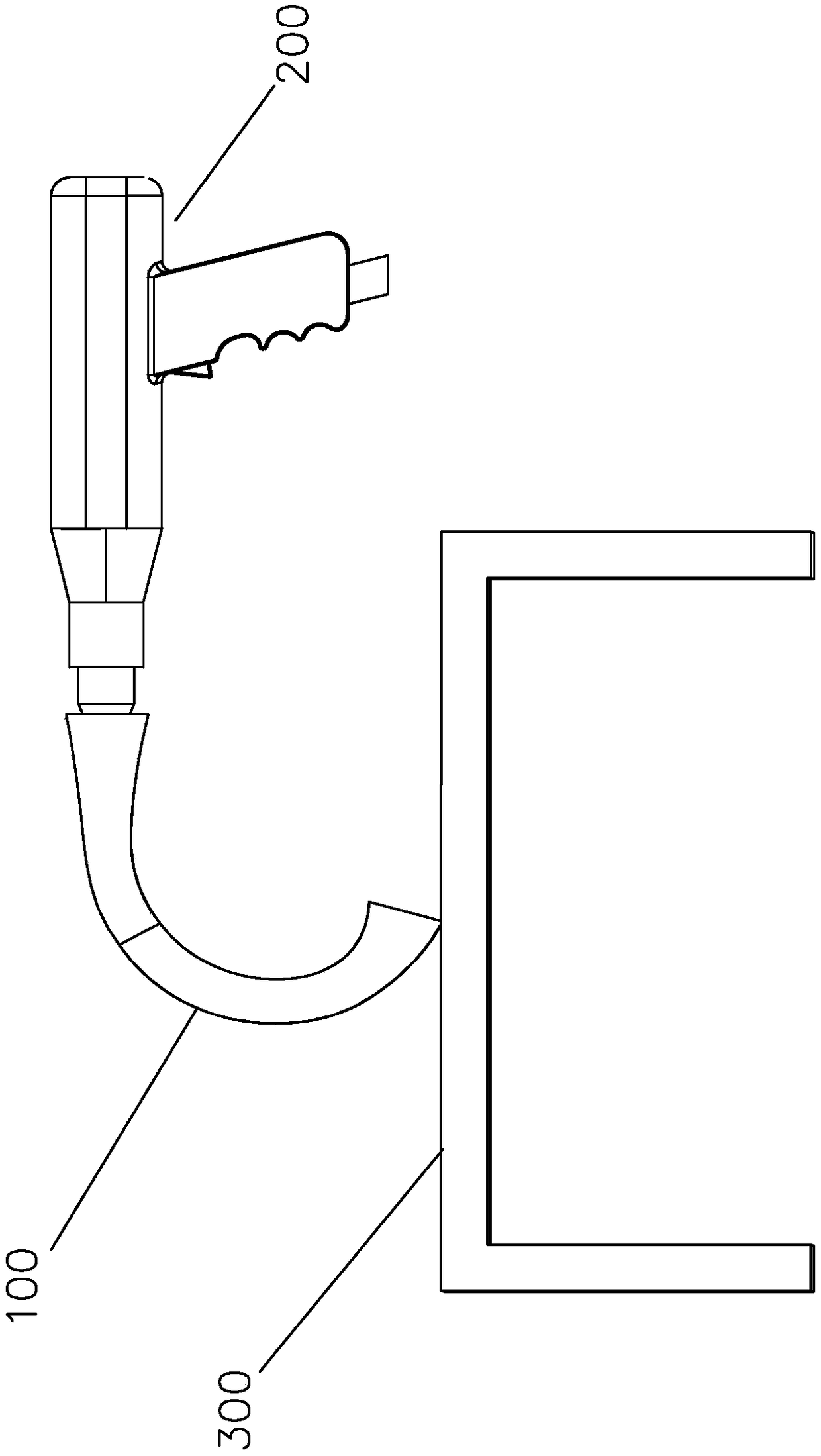

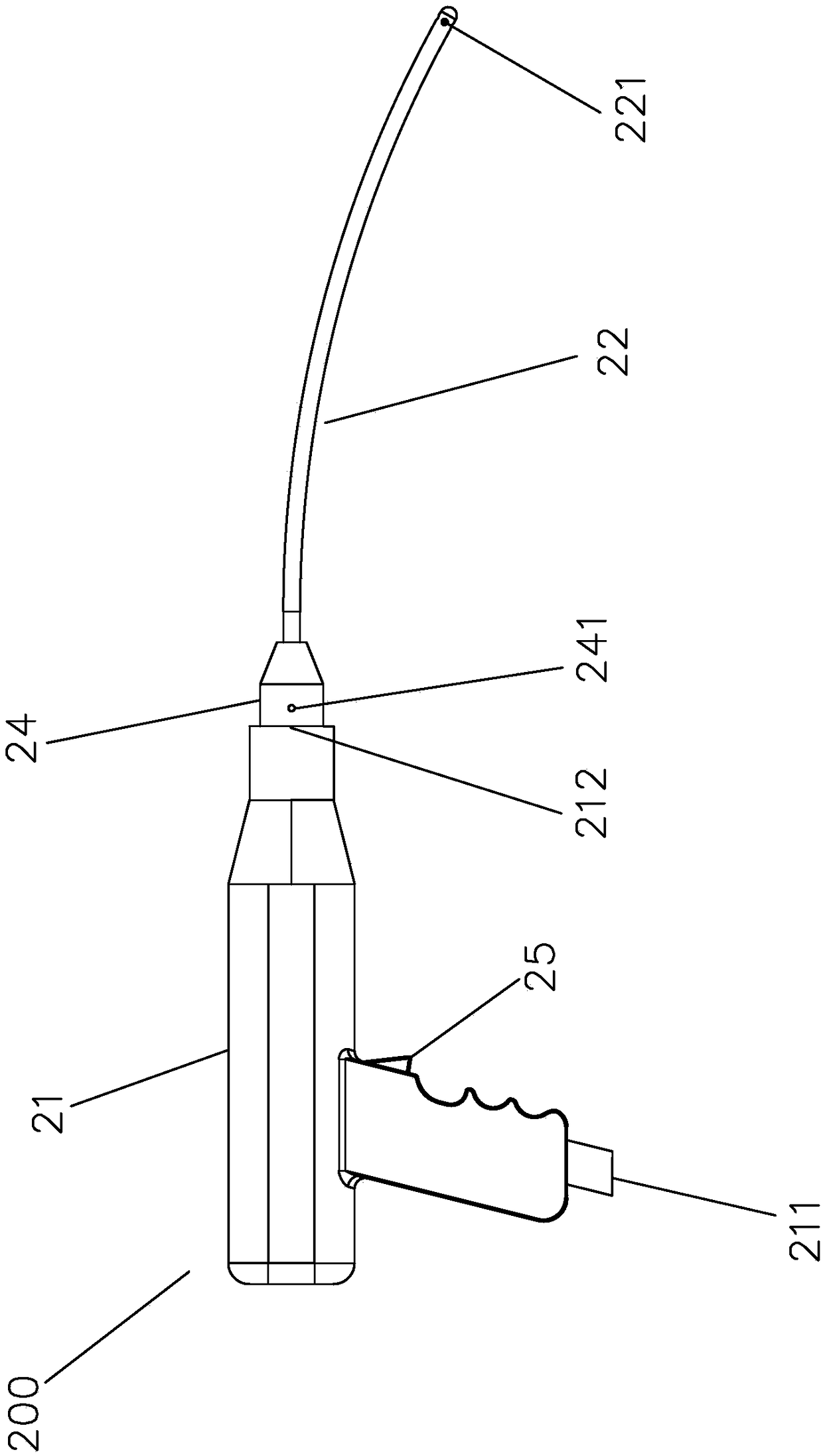

[0083] This case relates to a production process of a cast zinc alloy faucet. The present invention is mainly aimed at the zinc alloy faucet body 11 of a typical bathtub U-shaped zinc alloy faucet 100 (such as figure 1 , finished product wall thickness 2.0mm) for structural design and manufacturing process optimization. The U-shaped zinc alloy faucet body 11 passes through a food-grade polymer pipe as the inner water outlet pipe. The water inlet joint is made of lead-free brass to improve the connection strength of the pipe under the premise of ensuring lead-free. The water outlet is equipped with a bubbler.

[0084] The production process steps of the cast zinc alloy faucet are as follows:

[0085] A. The body of the zinc alloy faucet is formed by gravity casting;

[0086] B. Perform shot blasting and sandblasting pre-treatment on the zinc alloy faucet body; before shot blastin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com