Compound carbon source agent for wastewater treatment

A technology of compound carbon sources and chemicals, applied in the field of water treatment, can solve the problems of lower denitrification rate than methanol and sodium acetate, increase effluent COD, affect effluent quality, etc., so as to reduce treatment costs and sewage volume, and adapt to sludge bacteria species. Fast, low sludge yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

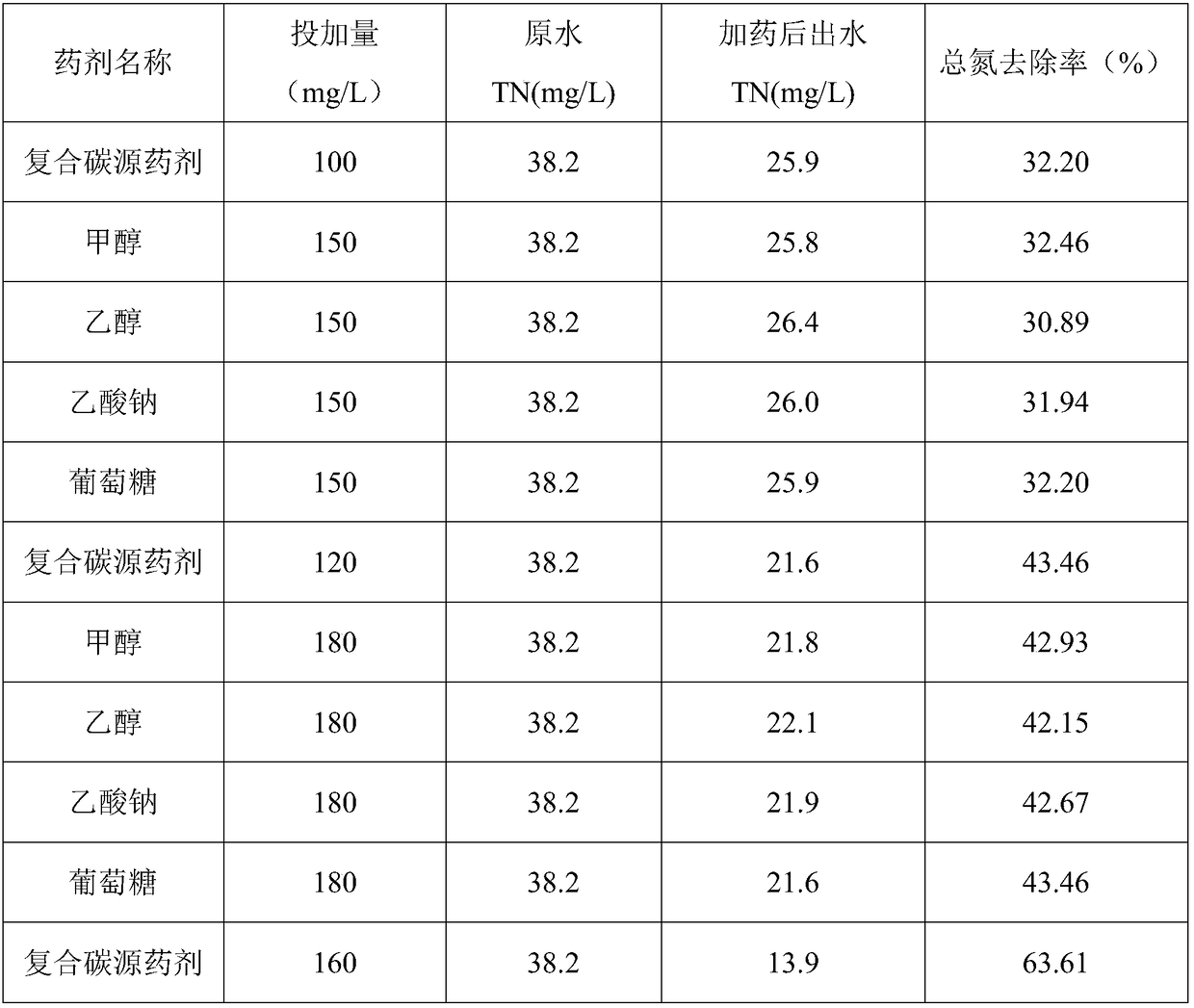

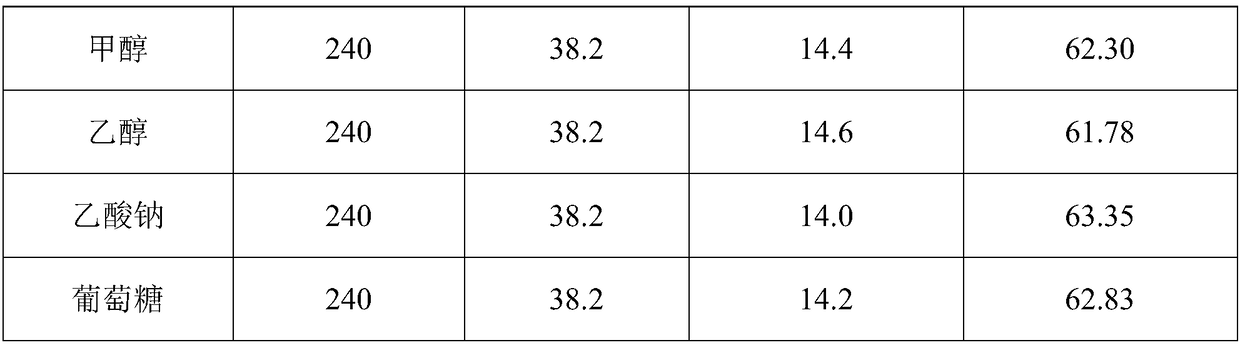

Examples

Embodiment 1

[0042] In the obtained composite carbon source agent: 0.5% of sodium formate, 5.5% of sodium acetate, 5.5% of sodium propionate, 44.5% of carbohydrates (glucose and fructose with a mass ratio of 2:1), and the rest is water.

[0043] Put the formic acid solution with a mass concentration of 20%, the acetic acid solution with a mass concentration of 20%, and the propionic acid solution with a mass concentration of 20% into the reactor in sequence according to the weight of 1.5%, 19%, and 19%, and gradually add the weight It is 16% sodium hydroxide solution with a mass concentration of 32%, and the rest is water. Start stirring, and after stirring for half an hour, control the temperature to 65-75°C, pH6.5-7.5, stop adding sodium hydroxide solution, and then slowly add glucose and fructose (mass ratio 2:1), continue to stir for 1 hour to mature, the reaction end temperature is 50°C (at this time COD 20-250,000 mg / L), filter to obtain a composite carbon source agent.

Embodiment 2

[0045] In the obtained composite carbon source agent: 0.7% of sodium formate, 5% of sodium acetate, 5% of sodium propionate, 45.5% of carbohydrates (xylose and fructose with a mass ratio of 1:1), and the rest is water.

[0046] Put the formic acid solution with a mass concentration of 20%, the acetic acid solution with a mass concentration of 20%, and the propionic acid solution with a mass concentration of 20% according to the weight of 2%, 18.5%, and 18.5% into the reactor in sequence, and slowly add the weight 15.5%, the mass concentration is 32% sodium hydroxide solution, the rest is water, and start stirring, after stirring for half an hour, control the temperature at 65-75°C, pH6.5-7.5, then slowly add xylose and fructose (mass Ratio 1:1), continue to stir for 1 hour to mature, the reaction end point temperature is about 50°C (at this time, COD reaches 200,000-250,000 mg / L), filter to obtain a composite carbon source agent.

[0047] Dosing point during wastewater treatme...

Embodiment 3

[0050] The obtained compound carbon source agent: contains 0.6% of sodium formate, 5.3% of sodium acetate, 5% of sodium propionate, 44.9% of carbohydrates (xylose and sucrose with a mass ratio of 1:1), and the rest is water.

[0051] Put the formic acid solution with a mass concentration of 20%, the acetic acid solution with a mass concentration of 20%, and the propionic acid solution with a mass concentration of 20% according to the weight of 1.8%, 18.8%, and 18.5% into the reactor in sequence, and slowly add the materials in batches The weight is 16%, the mass concentration is 32% sodium hydroxide solution, the rest is water, start stirring, after stirring for half an hour, control the temperature to 65-75°C, pH6.5-7.5, stop adding sodium hydroxide solution, and then slowly Add carbohydrates, continue to stir for 1 hour to mature, and the temperature at the end of the reaction is about 50°C (at this time, the COD reaches 200,000-250,000 mg / L), and filter to obtain a composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com