Method for separating and purifying p-hydroxyl ethyl cinnamate from camellia pollen, and uses of p-hydroxyl ethyl cinnamate

A technology for the separation and purification of ethyl cinnamate, which is applied in the separation/purification of carboxylic acid esters, chemical instruments and methods, and medical preparations containing active ingredients, etc. It can solve the problems of reducing product activity, long separation time, dead adsorption, etc. problem, to achieve the effect of reducing the cumulative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

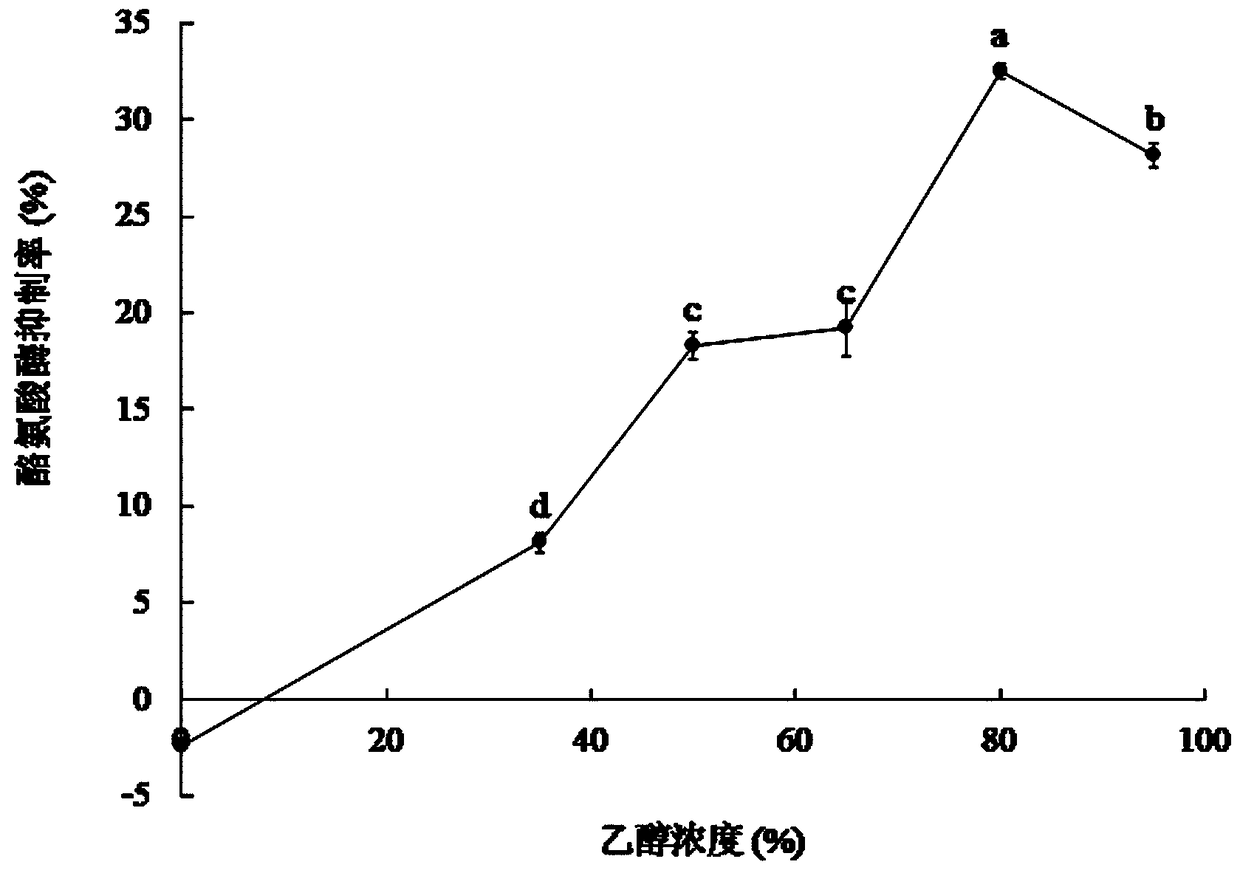

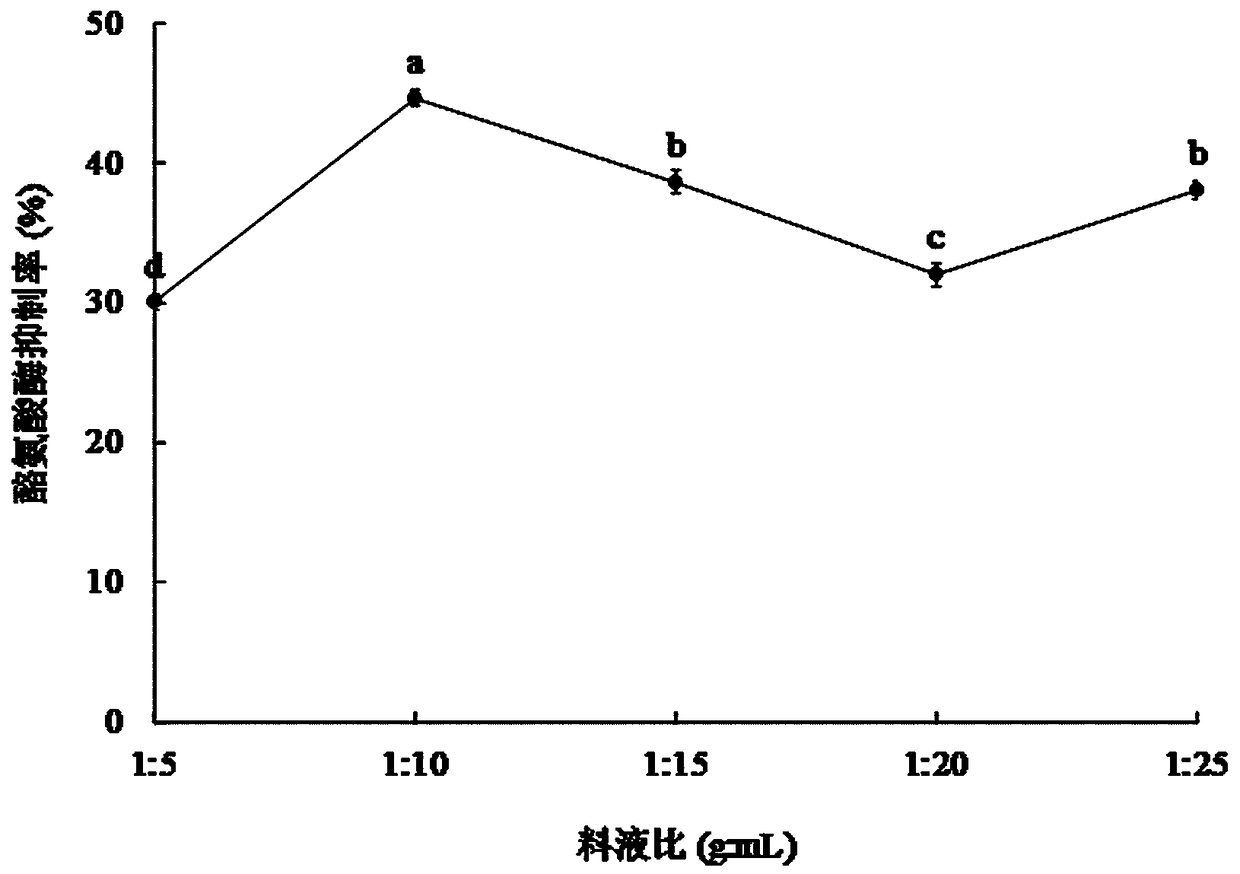

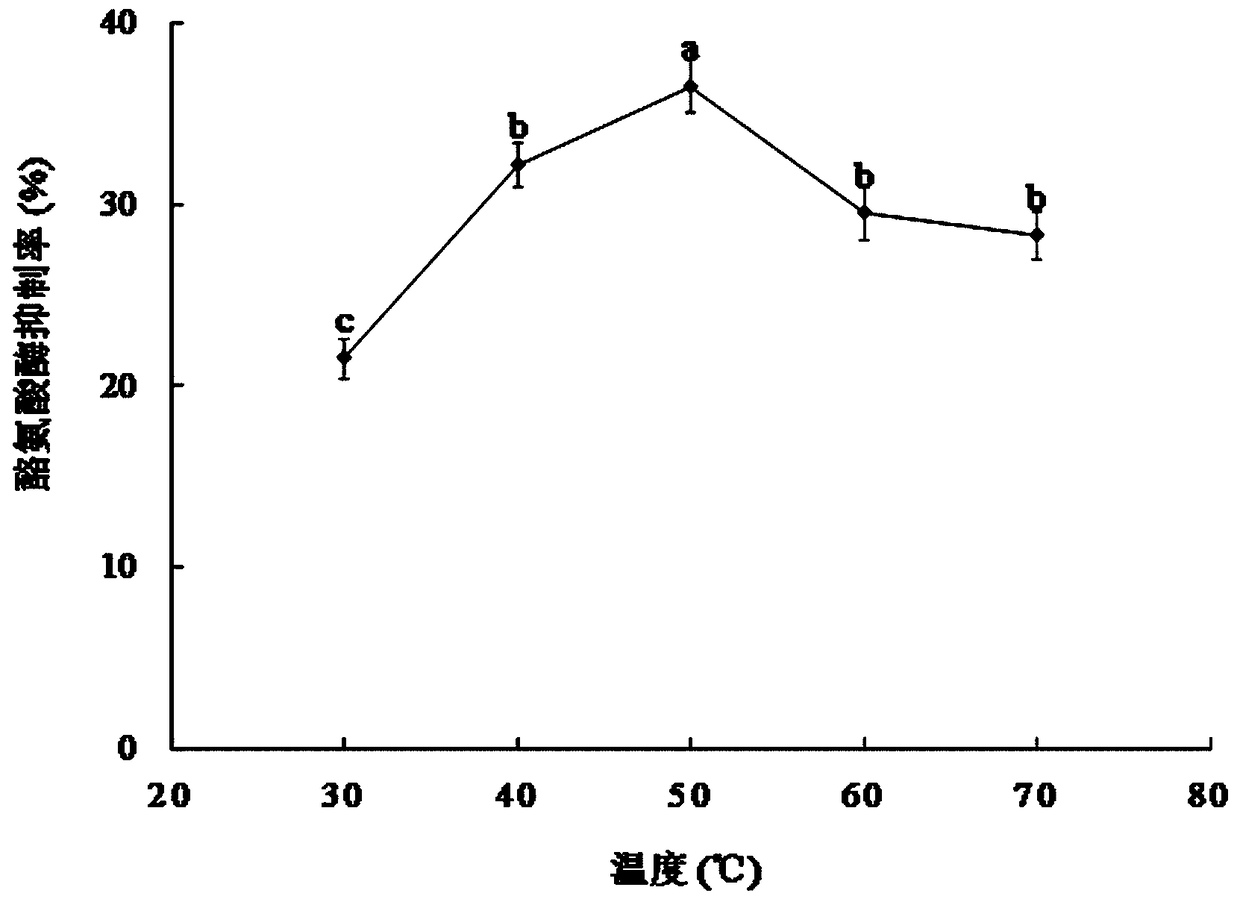

[0039] The influence of embodiment one ethanol concentration, solid-liquid ratio, temperature

[0040] S1. Extraction

[0041] Accurately weigh 1000g of camellia powder that has been pulverized by a high-speed universal pulverizer and sieved (40 mesh), add 0%-95% ethanol according to the ratio of material to liquid 1g:5mL-25mL, and store at 30°C-70°C Extracted under water bath conditions for 6 hours, extracted 3 times in total, obtained the supernatant by suction filtration, combined the supernatants, and concentrated under reduced pressure at 50°C to obtain an extract to obtain a crude extract, which was refrigerated at 4°C for later use.

[0042] S2, extraction

[0043]The crude extract obtained in step S1 was added into distilled water according to the ratio of solid to liquid 1g:10mL, stirred and dissolved, extracted with petroleum ether, ethyl acetate and n-butanol in sequence, all extracted 3 times, and then placed in a rotary evaporator at 50°C Concentrate under reduc...

Embodiment 2

[0056] Embodiment 2 The influence of rotating speed

[0057] The principle and steps of the method for separating and purifying ethyl p-hydroxycinnamate from tea pollen in this embodiment are basically the same as in Example 1, and the same places will not be described in detail, only the different places will be described, and the difference lies in: the steps In S1, the ethanol concentration is 80%, the solid-liquid ratio of camellia powder and 80% ethanol is 1 g:10 mL, and the extraction temperature is 50°C; in step S5, the rotating speed is 700rpm-900rpm; in step S5, the mobile phase The flow rate was 3 mL / min.

[0058] Result analysis:

[0059] Such as Figure 4 As shown, the greater the rotational speed, the greater the retention rate of the stationary phase. When the rotational speed was 700 rpm, the retention rate of the stationary phase exceeded 70%, reaching 70.66%. When the rotational speed continued to increase, the retention rate of the stationary phase reache...

Embodiment 3

[0060] Embodiment 3 The influence of flow rate

[0061] The principle and steps of the method for separating and purifying ethyl p-hydroxycinnamate from tea pollen in this embodiment are basically the same as in Example 1, and the same places will not be described in detail, only the different places will be described, and the difference lies in: the steps In S1, the ethanol concentration is 80%, the solid-liquid ratio of camellia powder and 80% ethanol is 1 g:10 mL, and the extraction temperature is 50° C.; in step S5, the rotating speed is 850 rpm; in step S5, the flow rate of mobile phase is 3mL / min-6mL / min.

[0062] Result analysis:

[0063] Such as Figure 5 As shown, with the increase of flow rate, the stationary phase retention rate showed a downward trend. When the flow rate is 3 mL / min, the maximum retention rate of the stationary phase is 75.83%, while when the flow rate is 6 mL / min, the retention rate of the stationary phase is only 66.66%. In order to obtain a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com