Polydopamine particles-doped star-shaped polymer of multi-responsive self-healing hydrogel, and self-healing hydrogel and preparation method thereof

A technology of polydopamine particles and star-shaped polymers, which is applied in the field of intelligent bionic materials, can solve problems such as destruction, hydrogen bond formation, and DMAEMA solubility reduction, and achieve the effects of wide sources, good bioadhesion, and high healing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

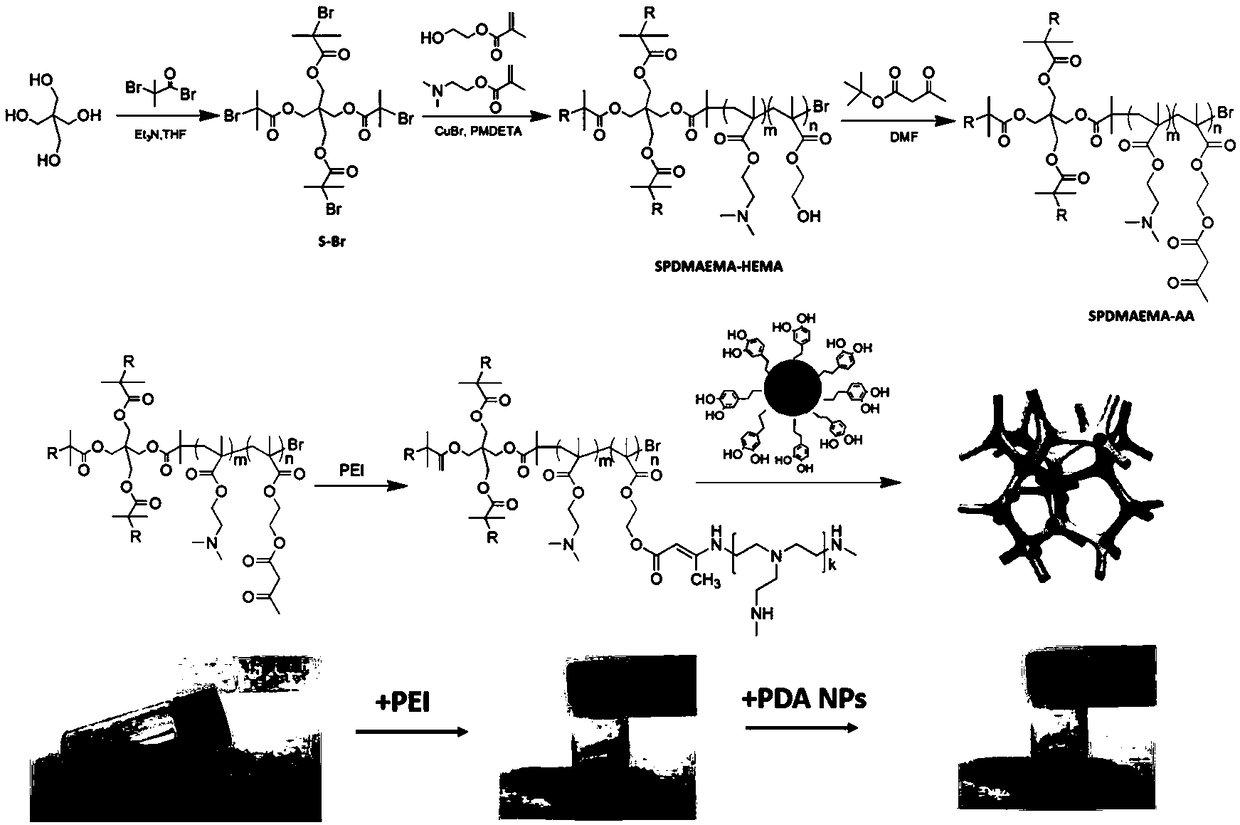

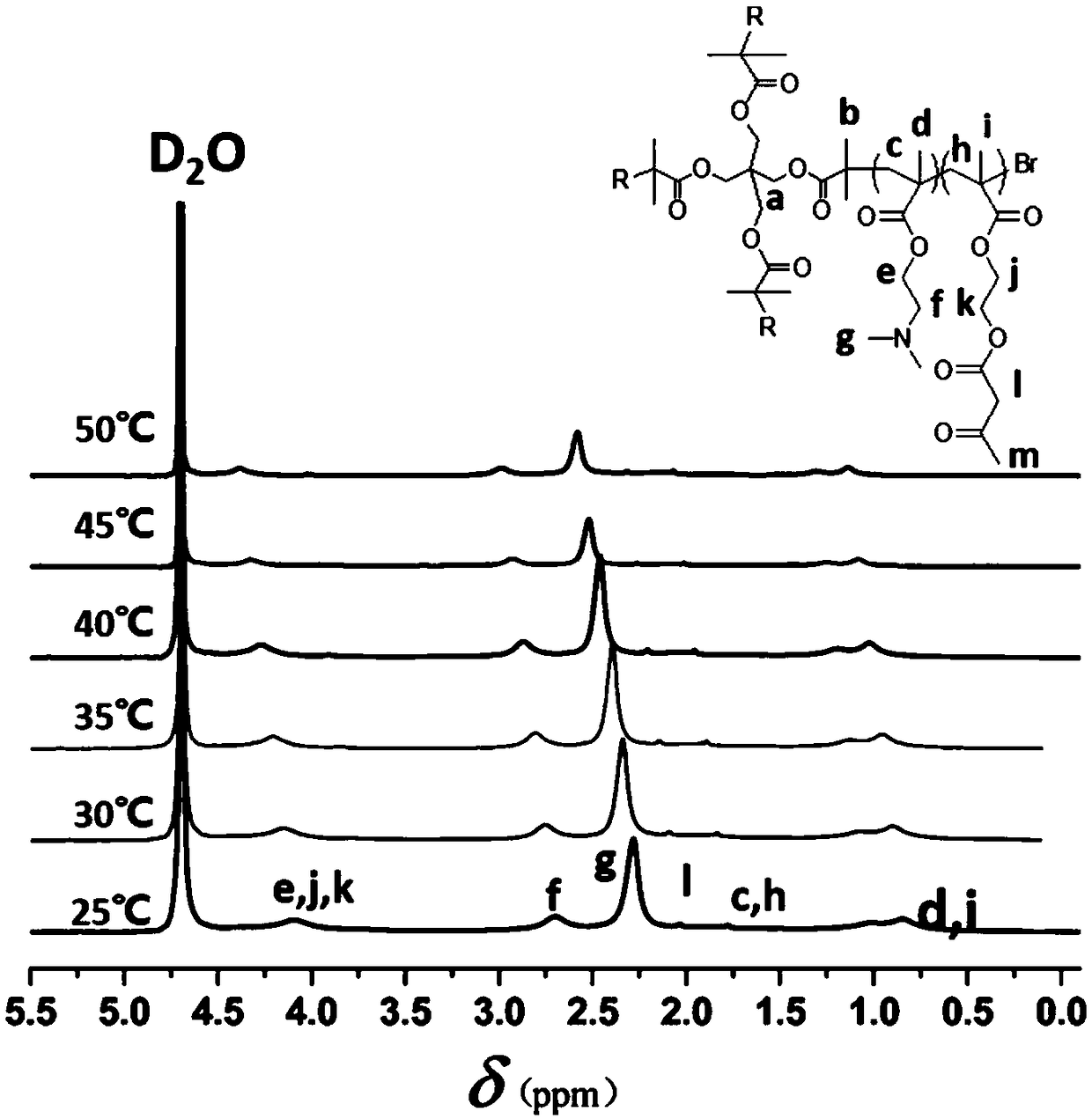

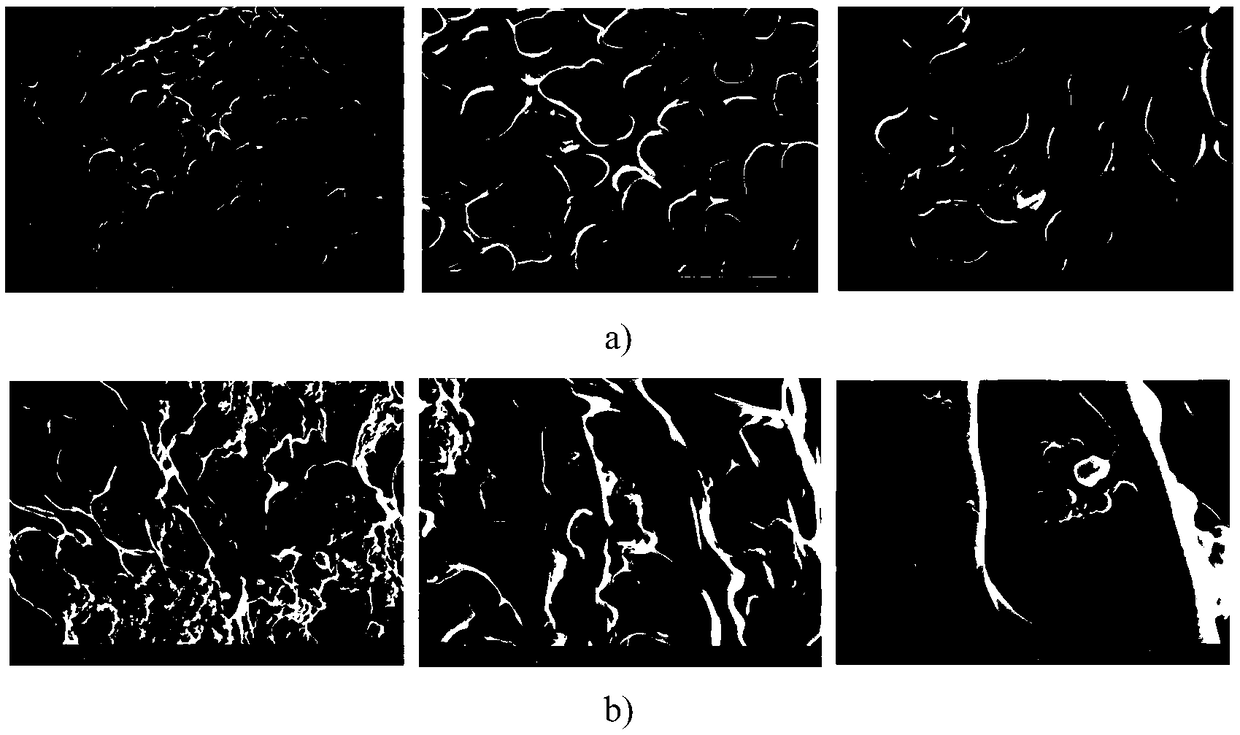

Method used

Image

Examples

Embodiment 1

[0033] Add 1.36g (0.01mol) of dry pentaerythritol, 50.00mL of dry tetrahydrofuran, and 8.22mL of dry triethylamine into the dry reaction flask, and dissolve 7.42mL (0.06mol) of 2-bromoisobutyryl bromide in 10.00 mL of tetrahydrofuran was slowly added dropwise to the flask; after sealing, it was protected from light and stirred vigorously for 24 hours; the product was mixed with a large amount of ether, and the product was washed with saturated sodium bicarbonate solution 4 times, and stood still; after obtaining the upper ether organic layer, add anhydrous Magnesium sulfate, remove water overnight; filter with suction, then transfer the obtained liquid into a flask, spin dry the solvent with a rotary evaporator, dissolve the product of the previous step with petroleum ether, freeze the product in the refrigerator for 1 hour for recrystallization, filter while cold, and then Wash the product several times with ethanol, put the product in a vacuum oven and dry it for 24 hours to ...

Embodiment 2

[0039] Add 1.36g (0.01mol) of dry pentaerythritol, 50.00mL of dry tetrahydrofuran, and 8.22mL of dry triethylamine into the dry reaction flask, and dissolve 7.42mL (0.06mol) of 2-bromoisobutyryl bromide in 10.00 mL of tetrahydrofuran was slowly added dropwise to the flask; after sealing, it was protected from light and stirred vigorously for 24 hours; the product was mixed with a large amount of ether, and the product was washed with saturated sodium bicarbonate solution 4 times, and stood still; after obtaining the upper ether organic layer, add anhydrous Magnesium sulfate, remove water overnight; filter with suction, then transfer the obtained liquid into a flask, spin dry the solvent with a rotary evaporator, dissolve the product of the previous step with petroleum ether, freeze the product in the refrigerator for 1 hour for recrystallization, filter while cold, and then Wash the product several times with ethanol, put the product in a vacuum oven and dry it for 24 hours to ...

Embodiment 3

[0044] Add 1.36g (0.01mol) of dry pentaerythritol, 50.00mL of dry tetrahydrofuran, and 8.22mL of dry triethylamine into the dry reaction flask, and dissolve 7.42mL (0.06mol) of 2-bromoisobutyryl bromide in 10.00 mL of tetrahydrofuran was slowly added dropwise to the flask; after sealing, it was protected from light and stirred vigorously for 24 hours; the product was mixed with a large amount of ether, and the product was washed with saturated sodium bicarbonate solution 4 times, and stood still; after obtaining the upper ether organic layer, add anhydrous Magnesium sulfate, remove water overnight; filter with suction, then transfer the obtained liquid into a flask, spin dry the solvent with a rotary evaporator, dissolve the product of the previous step with petroleum ether, freeze the product in the refrigerator for 1 hour for recrystallization, filter while cold, and then Wash the product several times with ethanol, put the product in a vacuum oven and dry it for 24 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com