A kind of corrosion-resistant polyvinyl chloride resin and preparation method thereof

A polyvinyl chloride resin and corrosion-resistant technology, which is applied in the field of corrosion-resistant polyvinyl chloride resin and its preparation, can solve the problems of deteriorating the chemical resistance of the polyvinyl chloride resin, and achieves ensuring corrosion resistance, improving corrosion resistance, Density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

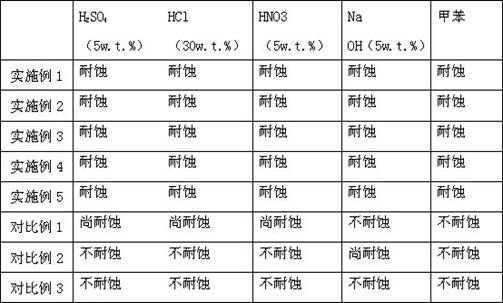

Examples

Embodiment 1

[0027] A preparation method of corrosion-resistant polyvinyl chloride resin, the specific steps are as follows:

[0028] (1) Dissolve the first dispersant in deionized water, then add the initiator and vinyl chloride monomer, disperse evenly and transfer to the polymerization kettle;

[0029] (2) Add the first part of cross-linking agent and heat to 50°C for polymerization;

[0030] (3) When the conversion rate of vinyl chloride monomer reaches 42%, add silane coupling agent, second dispersant, second part of crosslinking agent, toluene diisocyanate, isophorone diisocyanate, butyl acrylate, benzene peroxide Formyl, heat up to 75°C at a heating rate of 12°C / min for polymerization until the conversion rate of vinyl chloride monomer reaches 85%, end the polymerization, recover unreacted monomers, centrifuge and dry the obtained slurry to obtain polyvinyl chloride resin ;

[0031] (4) Kneading and extruding the polyvinyl chloride resin obtained in step (3) with rock wool and hig...

Embodiment 2

[0042] A preparation method of corrosion-resistant polyvinyl chloride resin, the specific steps are as follows:

[0043] (1) Dissolve the first dispersant in deionized water, then add the initiator and vinyl chloride monomer, disperse evenly and transfer to the polymerization kettle;

[0044] (2) Add the first part of cross-linking agent and heat to 60°C for polymerization;

[0045] (3) When the conversion rate of vinyl chloride monomer reaches 46%, add silane coupling agent, second dispersant, second part of crosslinking agent, toluene diisocyanate, isophorone diisocyanate, butyl acrylate, benzene peroxide Formyl, heat up to 80°C at a heating rate of 15°C / min for polymerization until the conversion rate of vinyl chloride monomer reaches 85%, then end the polymerization, recover unreacted monomers, centrifuge and dry the obtained slurry to obtain polyvinyl chloride resin ;

[0046] (4) kneading and extruding the polyvinyl chloride resin obtained in step (3) with rock wool an...

Embodiment 3

[0057] A preparation method of corrosion-resistant polyvinyl chloride resin, the specific steps are as follows:

[0058] (1) Dissolve the first dispersant in deionized water, then add the initiator and vinyl chloride monomer, disperse evenly and transfer to the polymerization kettle;

[0059] (2) Add the first part of cross-linking agent and heat to 50°C for polymerization;

[0060] (3) When the conversion rate of vinyl chloride monomer reaches 46%, add silane coupling agent, second dispersant, second part of crosslinking agent, toluene diisocyanate, isophorone diisocyanate, butyl acrylate, benzene peroxide Formyl, heat up to 80°C at a heating rate of 12°C / min for polymerization until the conversion rate of vinyl chloride monomer reaches 85%, end the polymerization, recover unreacted monomers, centrifuge and dry the obtained slurry to obtain polyvinyl chloride resin ;

[0061] (4) Kneading and extruding the polyvinyl chloride resin obtained in step (3) with rock wool and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com