Preparation method of compact ash-wrapping cigarette paper

A cigarette paper, dense technology, applied in the field of papermaking, can solve the problems of high beating degree of hemp pulp fiber, soot flying around, poor ash wrapping effect, etc., to achieve the effect of easy degradation, improved opacity and whiteness, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

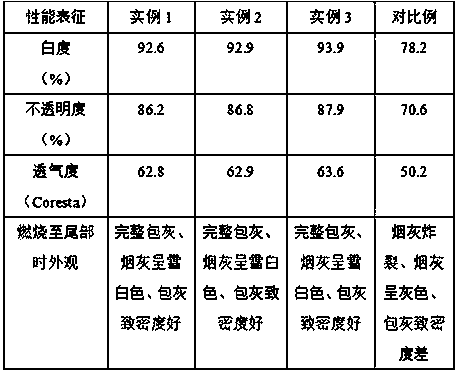

Examples

example 1

[0025] Mix the fiber slurry and sulfuric acid solution with a mass fraction of 50% at a mass ratio of 1:10, soak at room temperature for 10 minutes, and then place it in a constant temperature water bath at 50°C for 30 minutes to obtain a mixed solution. Ionized water, after diluting the acid concentration to 10%, stop the reaction to obtain suspension A, centrifuge at 3000r / min for 15min, discard the supernatant to obtain precipitate A, adjust with 2mol / L sodium hydroxide solution The system was neutral, then centrifuged and washed 4 times repeatedly, discarded the supernatant to obtain the precipitate B, put it in an oven with a temperature of 60°C and dried it to a constant weight to obtain cellulose whiskers; the mass ratio was 1:1 Cellulose whiskers and whisker calcium carbonate are evenly mixed to obtain fillers; in parts by weight, respectively weigh 50 parts of fiber slurry, 20 parts of fillers, and 1 part of combustion enhancer, and mix the fiber slurry in the mixing t...

example 2

[0027] Mix the fiber slurry and sulfuric acid solution with a mass fraction of 50% at a mass ratio of 1:10, soak at room temperature for 13 minutes, and then place it in a constant temperature water bath at 55°C for 35 minutes to react to obtain a mixed solution. Ionized water, after diluting the concentration of acid solution to 15%, stop the reaction to obtain suspension A, centrifuge at 3500r / min for 17min, discard the supernatant to obtain precipitate A, adjust with 2mol / L sodium hydroxide solution The system was neutral, then centrifuged and washed 4 times repeatedly, discarded the supernatant to obtain precipitate B, placed in an oven at 70°C and dried to constant weight to obtain cellulose whiskers; according to the mass ratio of 1:1, Cellulose whiskers and whisker calcium carbonate are evenly mixed to obtain fillers; in parts by weight, respectively weigh 60 parts of fiber slurry, 28 parts of fillers, and 4 parts of combustion enhancer, and mix the fiber slurry in the m...

example 3

[0029]Mix the fiber slurry and sulfuric acid solution with a mass fraction of 50% according to the mass ratio of 1:10, soak at room temperature for 15 minutes, and then place it in a constant temperature water bath at 60°C for 40 minutes to react to obtain a mixed solution, which is added to the mixed solution Ionized water, after diluting the concentration of acid solution to 20%, stop the reaction to obtain suspension A, centrifuge at 4000r / min for 20min, discard the supernatant to obtain precipitate A, adjust with 2mol / L sodium hydroxide solution The system was neutral, then centrifuged and washed 5 times repeatedly, discarded the supernatant to obtain precipitate B, placed in an oven at 80°C and dried to constant weight to obtain cellulose whiskers; according to the mass ratio of 1:1, Cellulose whiskers and whisker calcium carbonate are evenly mixed to obtain fillers; in parts by weight, 70 parts of fiber slurry, 36 parts of fillers, and 6 parts of combustion enhancer are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com