X-ray and gamma-ray radiation and neutron radiation protective material and preparation method thereof

A radiation protection and γ-ray technology, which is applied in shielding, nuclear engineering, reactors, etc., can solve the problems of no absorption and blocking of neutron radiation, high physical energy consumption, and inconvenient movement, and achieve good protection effect, light weight, and excellent toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

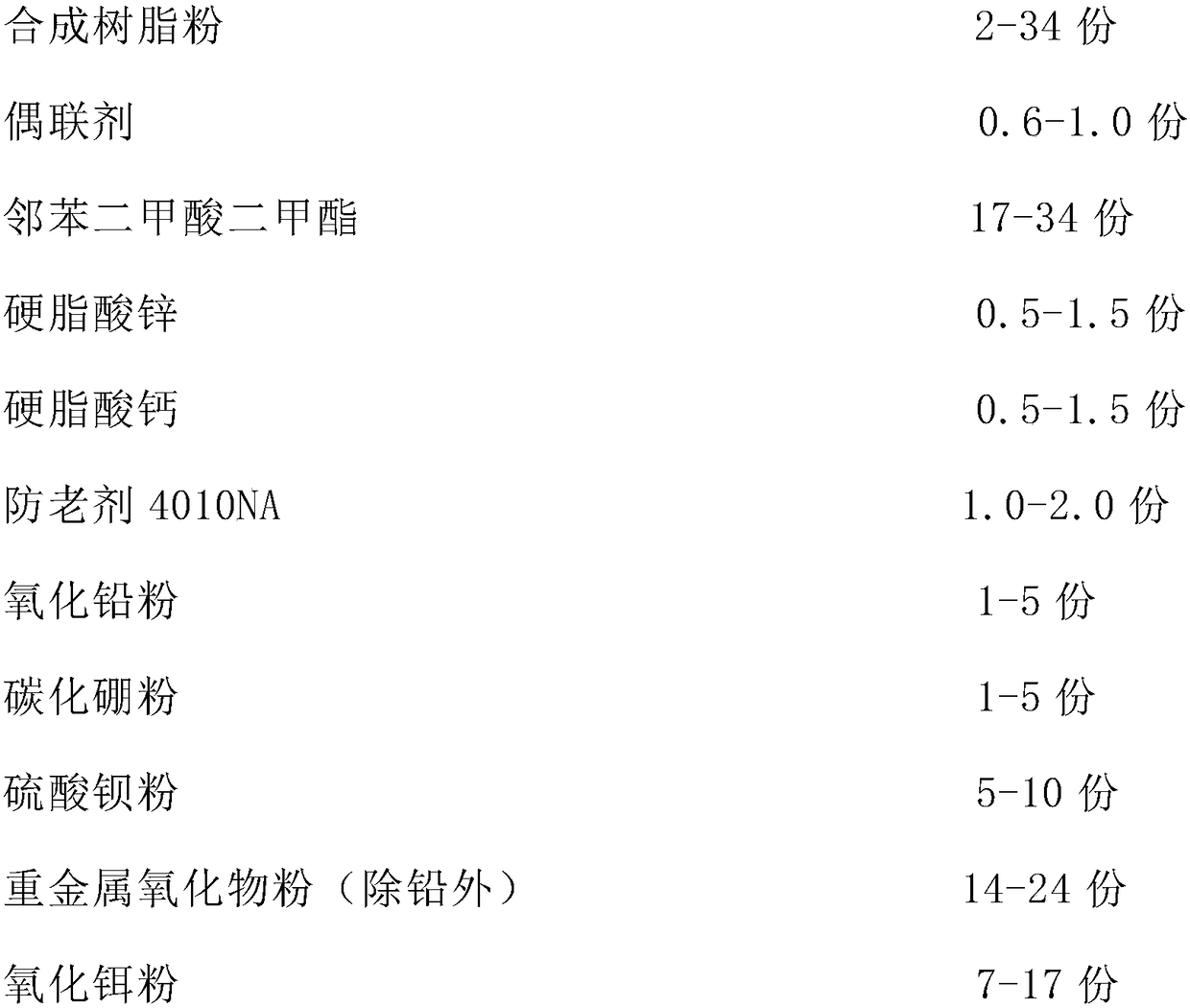

[0023] Embodiment 1, the method for preparing X, gamma ray radiation and neutron radiation protection material by emulsion polystyrene butadiene rubber

[0024] Step 1: Crush and sieve

[0025] Lead oxide powder, heavy metal oxide powder (except lead), and erbium oxide powder are processed and sieved (removing large particles and too small particles) according to their respective particle densities, and set aside for use;

[0026] With boron carbide powder and barium sulfate powder, according to the different particle densities, the powders are processed and sieved (to remove large particles and too small particles), and set aside;

[0027] Step 2: Modification and mixing

[0028] Put 2 parts of lead oxide powder, 20 parts of heavy metal oxide powder (except lead), and 8 parts of erbium oxide powder into a container filled with toluene, disperse, add excess hexamethylene diisocyanate, stir and heat After boiling for 20 minutes, cool, filter, dry, crush, and mix for 20 minute...

Embodiment 2

[0035] Embodiment 2, the method for preparing X, γ-ray radiation and neutron radiation protection material from butadiene rubber

[0036] Step 1: Crush and sieve

[0037] Lead oxide powder, heavy metal oxide powder (except lead), and erbium oxide powder are processed and sieved (removing large particles and too small particles) according to their respective particle densities, and set aside for use;

[0038] With boron carbide powder and barium sulfate powder, according to the different particle densities, the powders are processed and sieved (to remove large particles and too small particles), and set aside;

[0039] Step 2: Modification and mixing

[0040] Place 1.5 parts of lead oxide powder, 24 parts of heavy metal oxide powder (except lead), and 8 parts of erbium oxide powder into a container equipped with absolute ethanol for sampling, disperse, add excess methyl methacrylate, stir, Heat to boiling, after 20 minutes, cool, filter, dry, crush, and mix for 20 minutes wit...

Embodiment 3

[0047] Embodiment 3, the method for preparing X, gamma ray radiation and neutron radiation protection material from polyethylene

[0048] Step 1: Crush and sieve

[0049] Lead oxide powder, heavy metal oxide powder (except lead), and erbium oxide powder are processed and sieved (removing large particles and too small particles) according to their respective particle densities, and set aside for use;

[0050] With boron carbide powder and barium sulfate powder, according to the different particle densities, the powders are processed and sieved (to remove large particles and too small particles), and set aside;

[0051] Step 2: Modification and mixing

[0052] Put 2 parts of lead oxide powder, 20 parts of heavy metal oxide powder (except lead), and 8 parts of erbium oxide powder into a container filled with distilled water for sampling, disperse, add excess polyvinyl alcohol, stir, heat to boiling, After 20 minutes, cool, filter, dry, crush, and mix for 15 minutes at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lead equivalent | aaaaa | aaaaa |

| Lead equivalent | aaaaa | aaaaa |

| Lead equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com