High-performance composite material suitable for photovoltaic frames and preparation method of composite material

A composite material and high-performance technology, which is applied in the field of high-performance composite materials and its preparation, can solve problems such as high energy consumption in the production process, environmental pollution, and expensive aluminum alloy photovoltaic frames, and achieve good weather resistance and high specific modulus , the rich effect of basalt ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

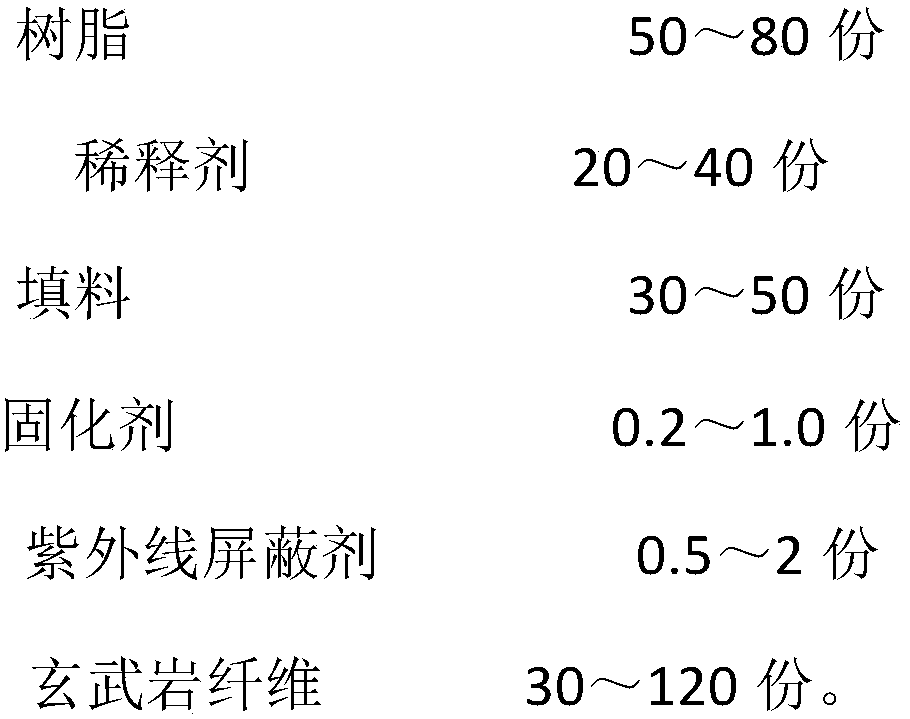

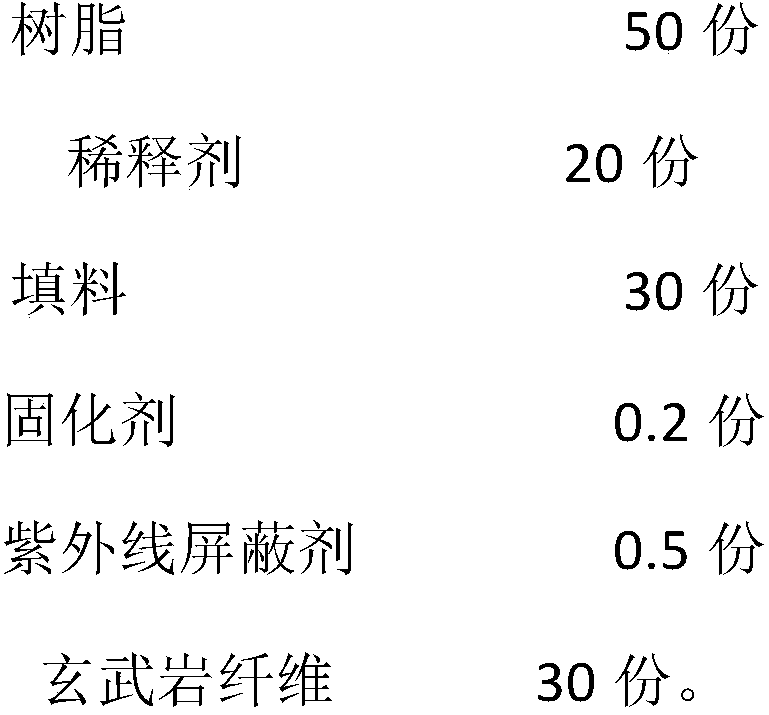

[0017] A high-performance composite material suitable for photovoltaic frames, comprising the following components in parts by weight:

[0018]

[0019] The resin is vinyl resin; the diluent is styrene monomer; the filler is kaolin; the curing agent is t-butyl peroxide; the ultraviolet shielding agent is titanium dioxide; the basalt fiber Direct yarn of 4800tex.

[0020] A method for preparing a high-performance composite material suitable for a photovoltaic frame, comprising the following steps:

[0021] 1) Put the resin in a stirring tank, then add curing agent, diluent, filler, ultraviolet shielding, stir for 2.5 hours and pour it into the glue tank;

[0022] 2) Place the basalt fiber on the creel, and the warp board enters the glue tank for impregnation, and then passes through the preforming mold and then puts it into the forming mold for curing and molding at 80°C.

Embodiment 2

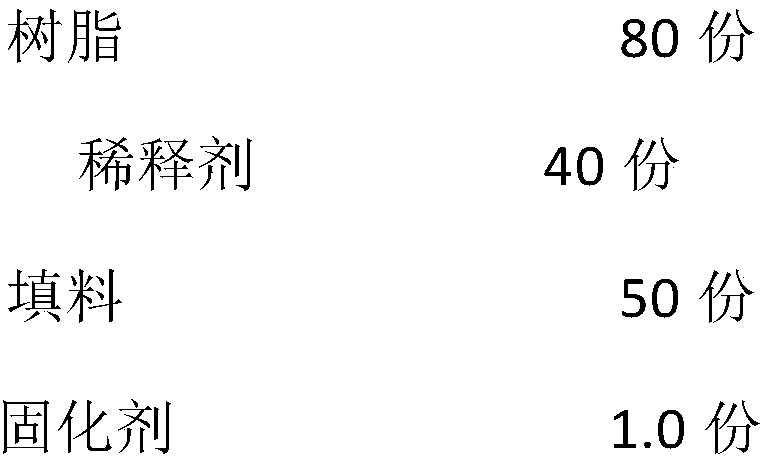

[0024] A high-performance composite material suitable for photovoltaic frames, comprising the following components in parts by weight:

[0025]

[0026]

[0027] The resin is an o-phthalic unsaturated resin; the diluent is a styrene monomer; the filler is a mixture of calcium carbonate and aluminum hydroxide; the curing agent is a mixture of methyl ethyl ketone peroxide and benzoyl peroxide; the ultraviolet shielding agent is A mixture of zinc oxide and UV326; the basalt fiber is 2400tex twisted yarn and 9600tex direct yarn.

[0028] A method for preparing a high-performance composite material suitable for a photovoltaic frame, comprising the following steps:

[0029] 1) Put the resin in a stirring tank, then add curing agent, diluent, filler, and ultraviolet shielding to it, stir for 2 hours and pour it into the glue tank;

[0030] 2) Place the basalt fiber on the creel, and the warp board enters the glue tank to impregnate, and then passes through the preforming mold ...

Embodiment 3

[0032] A high-performance composite material suitable for photovoltaic frames, comprising the following components in parts by weight:

[0033]

[0034] Described resin is vinyl resin and m-benzene unsaturated resin; Diluent is styrene monomer; Described filler is the mixture of calcium carbonate, talcum powder and mica powder; Described curing agent is benzoyl peroxide The mixture of acyl and cumene hydroperoxide; the ultraviolet shielding agent is a mixture of iron oxide and UV531; the basalt fiber is a direct yarn of 2400tex and a direct yarn of 9600tex.

[0035] A method for preparing a high-performance 21 composite material suitable for a photovoltaic frame, comprising the following steps:

[0036] 1) Put the resin in a stirring tank, then add curing agent, diluent, filler, ultraviolet shielding, stir for 3 hours and pour it into the glue tank;

[0037] 2) Put the basalt fiber on the creel, and the warp board enters the glue tank to impregnate, and then passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com