Superhydrophobic coating and preparation method thereof

A technology of super-hydrophobic coating and hydrophobic layer, which can be used in coatings, devices for coating liquids on surfaces, special surfaces, etc., which can solve the problems of poor marine environment and human health, unsuitable for large-area preparation, and expensive instruments. , to achieve the effect of good superhydrophobicity, low price, and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

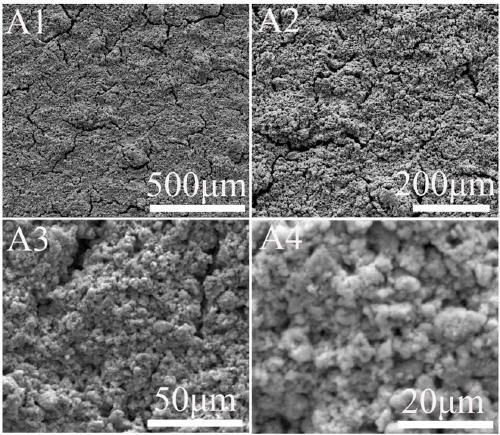

Image

Examples

Embodiment 1

[0032] (1) Grinding and cleaning of the substrate: Use an aluminum sheet as the metal substrate with a specification of 50*100*5mm, polish the aluminum sheet with 600# sandpaper for 10 minutes, and clean it with acetone, ethanol and distilled water for 1 minute respectively;

[0033] (2) Preparation of the hydrophobic layer suspension: mix nano-zinc oxide particles with silane coupling agent hexadecyltrimethoxysilane in a molar ratio of 4:1 to make modified nano-zinc oxide particles; The oxide particles are added to the ethanol solution of heptadecafluorodecyltriethoxysilane and left to stand to obtain modified nano-nickel particles;

[0034] Mix modified nano-zinc oxide particles, modified nano-nickel particles, and modified silicon dioxide in a mass ratio of 2:1:3 to form mixed particles, mix the mixed particles with acetone and water to form a suspension, and mix 1g of mixed particles with Mix 20ml of acetone aqueous solution, the volume of acetone in the acetone aqueous so...

Embodiment 2

[0040] (1) Grinding and cleaning of the substrate: Use an aluminum sheet as the metal substrate with a specification of 50*100*5mm, polish the aluminum sheet with 600# sandpaper for 10 minutes, and clean it with acetone, ethanol and distilled water for 1 minute respectively;

[0041] (2) Preparation of hydrophobic layer suspension: mix nano-zinc oxide particles with silane coupling agent hexadecyltrimethoxysilane in a molar ratio of 3:1 to make modified nano-zinc oxide particles; The oxide particles are added to the ethanol solution of heptadecafluorodecyltriethoxysilane and left to stand to obtain modified nano-nickel particles;

[0042] Mix modified nano-zinc oxide particles, modified nano-nickel particles, and modified silicon dioxide in a mass ratio of 4:0.5:2 to form mixed particles, mix the mixed particles with acetone and water to form a suspension, and mix 1g of mixed particles with Mix 20ml of acetone aqueous solution, the volume of acetone in the acetone aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com