Graphene/carbon nanotube composite electromagnetic shielding paper and preparation method thereof

A carbon nanotube composite and electromagnetic shielding technology, which is applied in papermaking, paper coating, textiles, and papermaking, can solve the problems of low shielding efficiency, poor mechanical properties, and complicated preparation process of electromagnetic shielding paper, and achieve low cost and improved electrical conductivity. The effect of simple performance and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

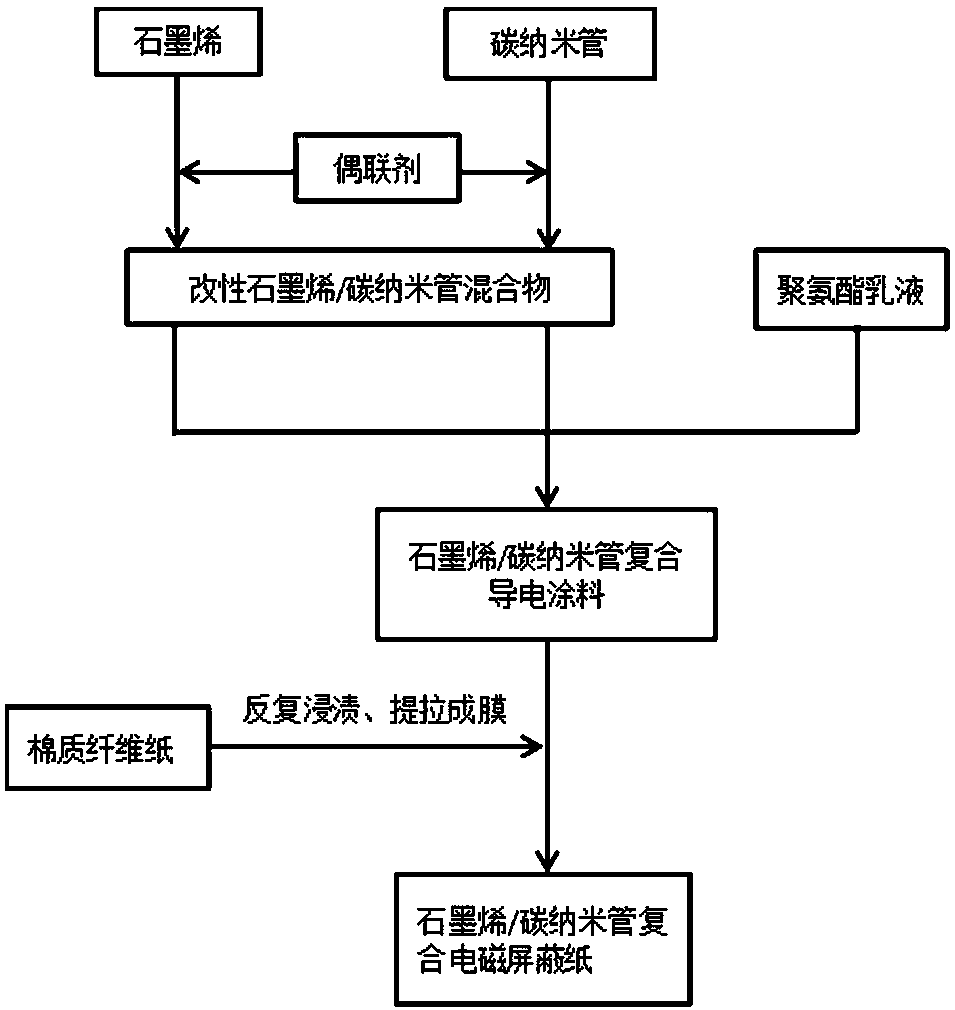

[0028] A graphene / carbon nanotube composite electromagnetic shielding paper and a preparation method thereof, comprising the following raw materials in parts by weight: 100 parts of polyurethane resin, 10 to 75 parts of graphene, 5 to 50 parts of carbon nanotubes, and 20 to 100 parts of silane coupling agent parts, 8~40 parts of deionized water, 72~360 parts of ethanol, 3~6 parts of surfactant, graphene and carbon nanotubes are lapped together by silane coupling agent, and the bonded graphene and carbon nanotubes are bonded together by polyurethane resin. Carbon nanotubes are fully dispersed and adsorbed on the surface of paper fibers.

[0029] The silane coupling agent is at least one of γ-aminopropyltriethoxysilane, γ-aminopropyltrimethoxysilane and anilinomethyltriethoxysilane.

[0030] The surfactant is at least one of sodium lauryl sulfate, sodium lauryl sulfate, cetyltrimethylammonium bromide, and polyvinylpyrrolidone.

[0031] figure 1 It is the process flow of the pr...

Embodiment 1

[0033] S1. Take 20 parts of γ-aminopropyltriethoxysilane, 8 parts of deionized water, and 72 parts of ethanol, mix and mechanically stir for 30 minutes to prepare a silane coupling agent dispersion;

[0034] S2. Weigh 10 parts of graphene and 5 parts of carbon nanotubes and add them to the S1 silane coupling agent dispersion. Under the heating condition of 60°C, the mixed solution is continuously stirred for 12 hours, the mixed solution is vacuum filtered, and the product is washed with ethanol for 3 Once, dry in an oven at 80°C to obtain a surface-modified graphene / carbon nanotube mixture;

[0035] S3. Add the surface-modified graphene / carbon nanotube mixture obtained in S2 and 3 parts of sodium lauryl sulfate to an aqueous polyurethane emulsion (containing 100 parts of polyurethane) with a solid content of 20%, and use them alternately at room temperature Ultrasonic and high-speed shear dispersion 3 times, each ultrasonic dispersion time is 2h, high-speed shear dispersion ti...

Embodiment 2

[0039] S1. Take 50 parts of γ-aminopropyltrimethoxysilane, 20 parts of deionized water, and 180 parts of ethanol, mix and mechanically stir for 30 minutes to prepare a silane coupling agent dispersion;

[0040]S2. Weigh 30 parts of graphene and 50 parts of carbon nanotubes and add them to the S1 silane coupling agent dispersion. Under the heating condition of 60°C, the mixed solution is continuously stirred for 12 hours, the mixed solution is vacuum filtered, and the product is washed with ethanol for 3 Once, dry in an oven at 80°C to obtain a surface-modified graphene / carbon nanotube mixture;

[0041] S3. Add the surface-modified graphene / carbon nanotube mixture obtained in S2 and 5 parts of polyvinylpyrrolidone to an aqueous polyurethane emulsion (containing 100 parts of polyurethane) with a solid content of 15%, and alternately use ultrasound and high-speed at room temperature Shear dispersion 3 times, each ultrasonic dispersion time is 2h, high-speed shear dispersion time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com