Preparation method of trimesic acid complex/titanium dioxide composite photoanode

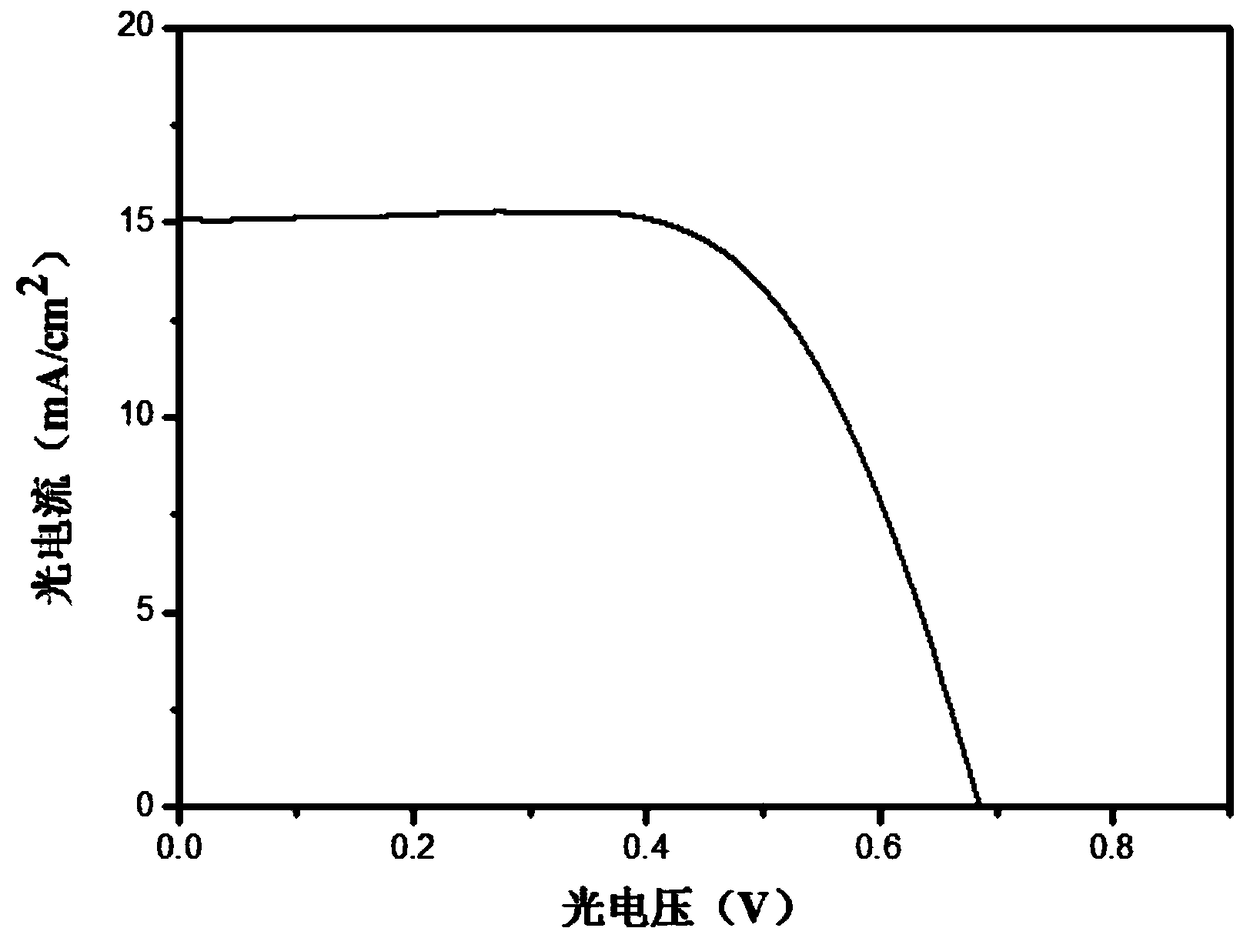

A technology of trimesic acid and titanium dioxide, which is applied in the direction of photosensitive equipment, photovoltaic power generation, electrolytic capacitors, etc., to achieve the effect of improving photocurrent and light utilization rate, simple equipment, and improving capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] Specific embodiment one: a preparation method of a trimesic acid complex / titanium dioxide composite photoanode described in this embodiment, the method includes the following steps:

[0035] Step 1, dissolving solid trimesic acid with an organic solvent, adding it to solution A after the dissolution is completed, and stirring evenly, the solution A is a mixed solution composed of europium chloride solution and yttrium chloride solution;

[0036] The mass ratio of solid trimesic acid to organic solvent is 1: (3590~3650);

[0037] The mol ratio of the europium chloride in the europium chloride solution and the yttrium chloride in the yttrium chloride solution is 1:(2~20):

[0038] The volume ratio of solution A to organic solvent is 1:(4~50);

[0039] Step 2, heat-treating the uniformly stirred mixed solution for 2 hours to 48 hours, and the temperature range of the heat treatment is 55°C to 80°C, to obtain nanocrystals of trimesic acid complexes containing impurities; ...

specific Embodiment approach 2

[0045] Embodiment 2: The difference between this embodiment and the method for preparing a trimesic acid complex / titanium dioxide composite photoanode described in Embodiment 1 is that in step 5, the coating thickness is 5 um to 10 um. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and the preparation method of a trimesic acid complex / titanium dioxide composite photoanode described in specific embodiment one is that in step one, the amount of europium chloride solution and yttrium chloride solution The concentrations are all 0.05mol / L-2mol / L, and the solutes in the europium chloride solution and the yttrium chloride solution are both hexahydrate chlorides, and the solvents of both are distilled water. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com