Preparation and application of natural vegetable oil modified MOF structure polyoxides

A vegetable oil and oxide technology, applied in structural parts, electrical components, electrochemical generators, etc., can solve the problems of poor cycle stability, rate performance, significant volume expansion effect, low first coulomb efficiency, etc. Poor performance and cycle performance, easy to implement and control, enhance the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

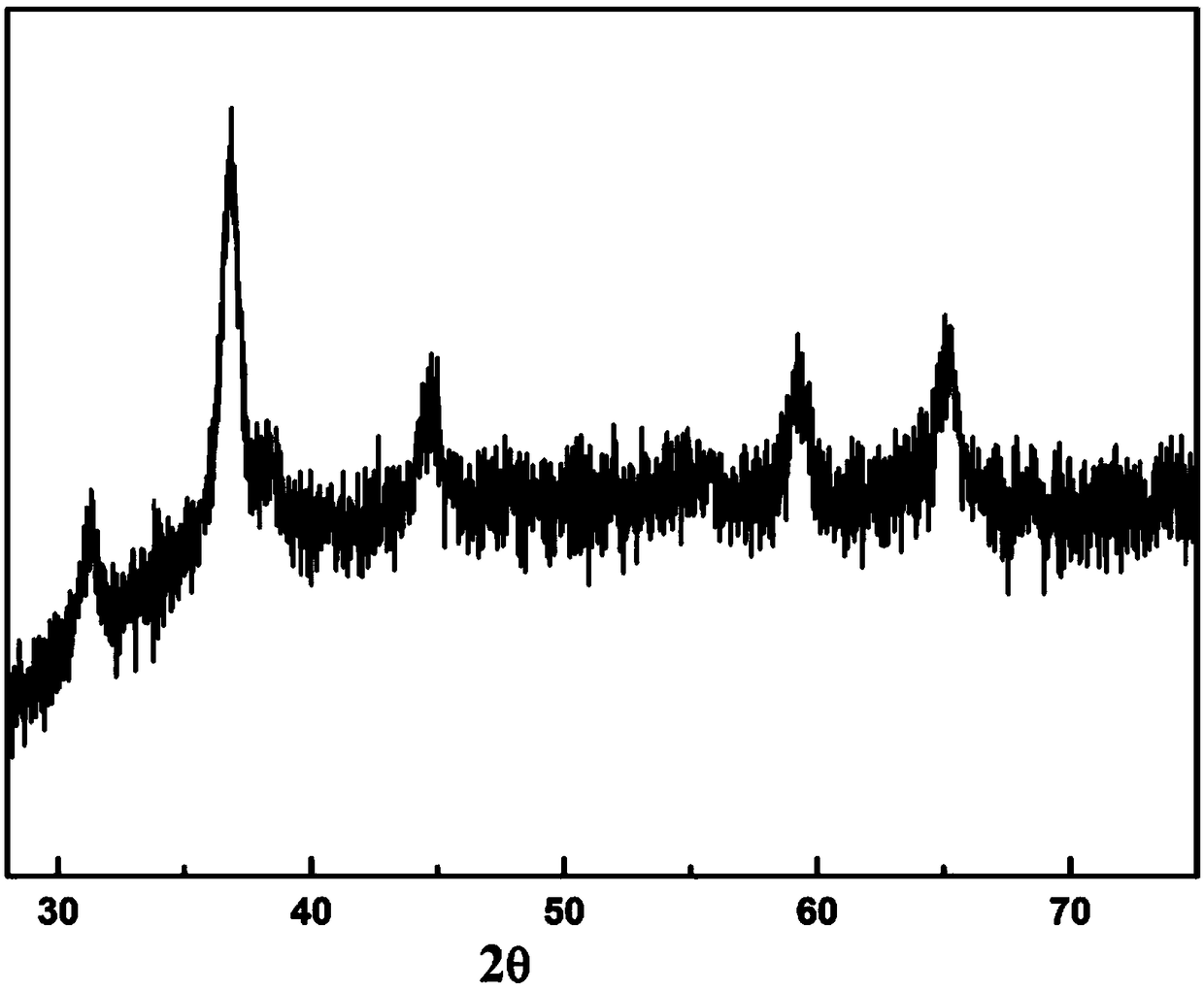

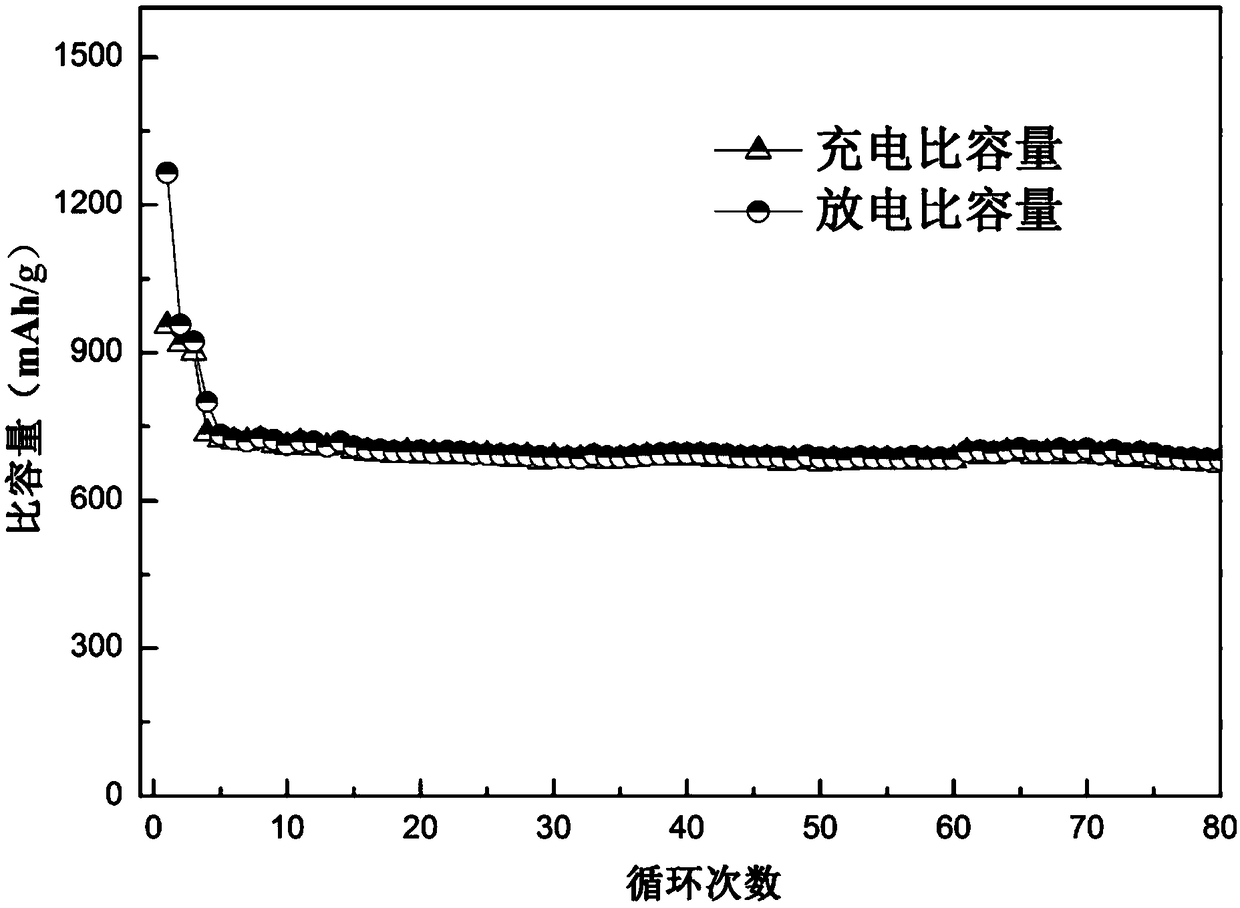

[0031]The preparation method of the multiple oxides of natural vegetable oil modified MOF structure of the present invention comprises the following steps:

[0032] (1) Precursor preparation:

[0033] Mix natural vegetable oil, surfactant and co-surfactant to prepare solution A; dissolve nickel salt and cobalt salt in water to prepare solution B; use the dispersion of nano-titanium dioxide as solution C; The organic acid of carboxyl functional group is mixed with water to prepare D solution;

[0034] Under the condition of stirring in a water bath at 30-60°C, mix solution A and solution D, then add solution B and solution C dropwise in turn to form a water-in-oil type emulsion, continue to stir under the condition of a water bath at 30-60°C, and then carry out After cooling, separating and drying, the precursor is obtained.

[0035] Wherein, the natural vegetable oil is obtained by pressing or extracting, and is one or more of soybean oil, linseed oil, peanut oil, corn oil, ...

Embodiment 1

[0044] In this embodiment, the steps for preparing the multi-component oxide of natural vegetable oil modified MOF structure are as follows:

[0045] (1) Precursor preparation:

[0046] To prepare solution A, mix and stir 200ml of soybean oil, 6g of cetyltrimethylammonium bromide (CTAB) and 10ml of n-pentanol in a water bath at 40°C until uniformly dispersed to obtain solution A.

[0047] To prepare solution B, mix and stir 20ml of deionized water, 4mmol of nickel nitrate and 8mmol of cobalt nitrate in a water bath at 40°C until it becomes clear and transparent to obtain solution B.

[0048] To prepare solution C, disperse 0.1 g of nano-titanium dioxide in 20 ml of deionized water to obtain solution C.

[0049] To prepare solution D, mix and stir 20ml of deionized water and 10mmol oxalic acid in a water bath at 40°C until it becomes clear and transparent to obtain solution D.

[0050] Under the condition of stirring in a water bath at 40°C, mix solution A and solution D, the...

Embodiment 2

[0056] In this embodiment, the steps for preparing the multi-component oxide of natural vegetable oil modified MOF structure are as follows:

[0057] (1) Precursor preparation:

[0058] To prepare solution A, mix and stir 200ml linseed oil, 6g lauryltrimethylammonium chloride (DTAC) and 10ml n-amyl alcohol in a water bath at 40°C until uniformly dispersed to obtain solution A.

[0059] To prepare solution B, mix and stir 20ml of deionized water, 4mmol of nickel nitrate and 8mmol of cobalt nitrate in a water bath at 40°C until it becomes clear and transparent to obtain solution B.

[0060] To prepare solution C, disperse 0.1 g of nano-titanium dioxide in 20 ml of deionized water to obtain solution C.

[0061] To prepare solution D, mix and stir 20ml of deionized water and 10mmol of citric acid in a water bath at 40°C until it becomes clear and transparent to obtain solution D.

[0062] Under the condition of stirring in a water bath at 40°C, mix solution A and solution D, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com