Hydroxyl oxidize iron modified titanium dioxide composite photocatalyst as well as preparation method and application thereof

A technology of iron oxyhydroxide and titanium dioxide, which is applied in the field of photocatalytic materials, can solve the problems of reducing the recombination rate of electron-hole pairs, few reports of photocatalytic desulfurization, and low photocatalytic efficiency, so as to alleviate the phenomenon of photocorrosion and facilitate the promotion Application, abundant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 FeOOH

[0024] Take 5g FeSO 4 ·7H 2 O was dissolved in deionized water at 70°C, and heated in a constant temperature heating magnetic stirrer to keep the water temperature stable at 70°C, and then slowly added 5g Na 2 CO 3 Powder, adjust the pH to 8 at room temperature after reacting for 1 hour, filter after aging for 3 hours, and wash with hot water at 60°C for several times until it is washed with BaCl 2 Titrate the filtrate with the solution until no obvious precipitation is formed, then dry the filter residue on a watch glass and dry it in an oven to obtain FeOOH.

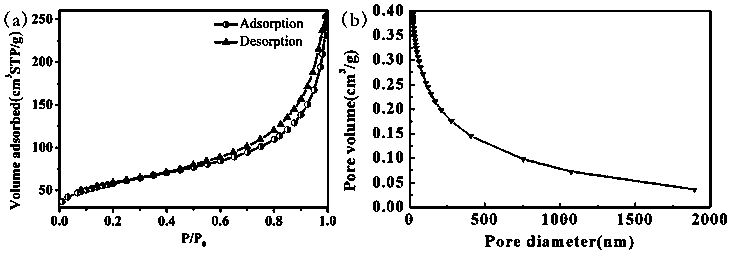

[0025] figure 1 The nitrogen adsorption-desorption curve (a) and pore size distribution (b) of the obtained FeOOH sample. After calculation, its specific surface area is 199.49m 2 / g, indicating that the prepared FeOOH sample has a larger specific surface area.

Embodiment 2

[0026] Example 2 TiO 2 preparation of

[0027] Add titanium tetrachloride to deionized water, slowly add 8wt% dilute ammonia water dropwise under vigorous stirring to adjust the pH of the solution to 12, leave the obtained white precipitate to age for 4 hours, then repeatedly filter and wash with deionized water to the pH of the eluate is 10, the filter cake is dissolved in distilled water and adjusted to pH 8 with 3.8mol / L dilute nitric acid, and TiO is obtained by ultrasonic treatment 2 Sol, which were calcined at 100°C, 200°C, and 300°C for 10-30h respectively.

Embodiment 3

[0028] Example 3 FeOOH / TiO 2 preparation of

[0029] The FeOOH that embodiment 1 makes and the TiO that does not calcined after ultrasonic in embodiment 2 2 Sol according to FeOOH and TiO 2 The molar ratio is 1:100, and mechanically stirred with a magnetic stirrer to ensure that the sample is evenly mixed, and then the mixed solution is divided into four times, and sprayed evenly on the front and back sides of the 60×80cm glass fiber sheet with a spray gun. After each side is sprayed , dry at room temperature, and then spray the next side, repeat the operation. Wait for both sides to dry naturally, put them in an oven to dry, and then calcinate at 100°C, 200°C, and 300°C for 10-30 hours to obtain a composite photocatalyst.

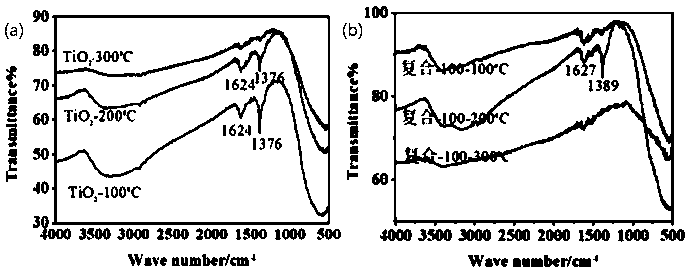

[0030] figure 2 TiO obtained by calcination at different temperatures 2 (a) with FeOOH / TiO 2 (b) FTIR spectrum. Depend on figure 2 It can be seen that the unmodified TiO 2 At 3430, 1624, 1376cm -1 TiO 2 The characteristic absorption peak of , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com