Preparation method and application of pitch-based low graphitized carbon material

A graphitized carbon, pitch-based technology, applied in carbon preparation/purification, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of limited lithium ion storage capacity and small graphite layer spacing, and achieve excellent cycle performance, operation The effect of few steps and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of preparation method of pitch-based low graphitization carbon material of the present invention, comprises the following steps:

[0018] Step 1. Heat the coal tar pitch to 400-430°C, react under normal pressure for 1-3 hours, and vacuum distill for 0.5-1 hour to obtain molten coal tar pitch;

[0019] Step 2, adding epoxy resin to the molten coal tar pitch under stirring conditions to obtain a mixture of coal tar pitch and epoxy resin, the mass ratio of epoxy resin to coal tar pitch is 0.1 to 2:1; after cooling to room temperature, crush the mixture;

[0020] Step 3. Put the mixture powder prepared in step 2) into a carbonization furnace, heat to 700-1000° C. under an inert atmosphere, and obtain a pitch-based low graphitization carbon material after cooling.

[0021] A pitch-based low-graphitizable carbon material for use as an anode for lithium-ion batteries.

Embodiment 1

[0024] In this example, the process of preparing pitch-based low graphitized carbon material is as follows:

[0025] 1) Heat 50 g of coal tar pitch with a softening point of 65°C to 400°C, react at normal pressure for 3 hours, and vacuum distill for 0.5 hour to obtain molten coal pitch;

[0026] 2) Add 20g of epoxy resin to the above-mentioned molten coal tar pitch and stir, after mixing evenly, cool to room temperature and pulverize the mixture;

[0027] 3) Carbonize the obtained mixture powder, raise the temperature to 700°C at 5°C / min under the protection of an inert gas in a tube furnace and maintain it for 2h, take it out after cooling, and obtain a pitch-based low graphitizable carbon material.

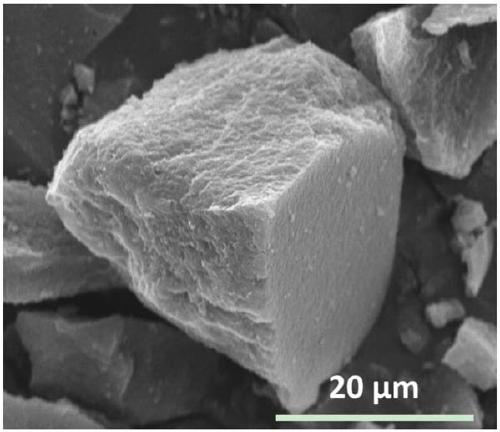

[0028] The scanning electron micrographs of the prepared pitch-based low graphitized carbon materials are as follows: figure 1 shown.

[0029] The prepared pitch-based low-graphitized carbon material, acetylene black, and PVDF (polyvinylidene fluoride) were prepared as negativ...

Embodiment 2

[0032] In this example, the process of preparing pitch-based low graphitized carbon material is as follows:

[0033] 1) heating 30 g of coal tar pitch with a softening point of 65°C to 430°C, reacting at normal pressure for 1 hour, and vacuum distillation for 1 hour to obtain molten coal tar pitch;

[0034] 2) Add 30g of epoxy resin to the above-mentioned molten coal tar pitch and stir, mix evenly, after cooling to room temperature, pulverize the mixture;

[0035] 3) Carbonize the obtained mixture powder, raise the temperature to 800°C at 3°C / min under the protection of an inert gas in a tube furnace and maintain it for 1h, take it out after cooling, and obtain a pitch-based low graphitizable carbon material.

[0036] The prepared pitch-based low-graphitized carbon material, acetylene black, and PVDF (polyvinylidene fluoride) were prepared as negative electrode materials in a mass ratio of 7:2:1. The current collector was copper foil, and a lithium-ion battery was assembled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com