Synthetic method of metallic oxide nanospheres

A technology of nano-microspheres and synthesis methods, applied in the direction of rare earth metal oxides/hydroxides, rare earth metal compounds, chemical instruments and methods, etc., can solve the problems of difficult process control and difficult to obtain nanostructures, and achieve easy operation, Good repeatability and controllable nanoparticle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

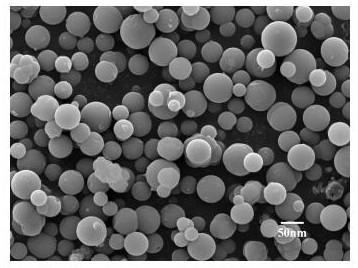

Image

Examples

Embodiment 1

[0033]Take 6.23 g of cetyl alcohol ethoxylate-20 (Brij®58) and 30 mL of cyclohexane in an oil bath environment at 50°C, stir magnetically at a rate of 500 rpm for 1 h to form a microemulsion system, and then add Add 0.6 mL of ethylene glycol and 0.45 mL of glacial acetic acid, stir well, then add 0.05 g of N-sulfonic acid butylpyridine bisulfate, stir well to obtain a mixed solution, and finally add 0.3 mL of tetra-n-titanate to the mixed solution Butyl ester, after mixing evenly, placed in 50 ° C constant temperature stirring reaction for 8 h, after the completion of the reaction, the system was cooled to room temperature, and then added ethanol and water in the final reaction liquid with a volume ratio of 1:3 prepared eluent Perform demulsification and precipitation, centrifuge to obtain solid particles, elute the solid particles with an eluent prepared with ethanol and water at a volume ratio of 1:3, then centrifuge at 8000 rpm for 30 min, repeat the elution 2 to 3 times, an...

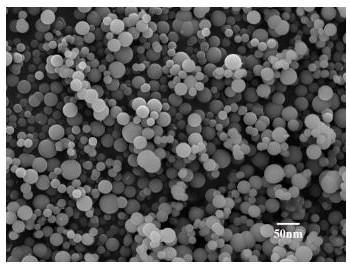

Embodiment 2

[0036] Under anhydrous conditions, take 5.98 g of nonylphenol polyoxyethylene ether and 30 mL of cyclohexane in an oil bath at 50°C, stir magnetically at a rate of 500 rpm for 1 h, then add 3 mL of butanol to form a microemulsion system, and then Add 0.6 mL of ethylene glycol and 0.45 mL of glacial acetic acid to the microemulsion system, stir well, then add 0.05 g of mixed acid (concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 1:1), stir well to obtain a mixed solution, and finally Add 0.3 mL of tetra-n-butyl titanate to the mixed solution, mix evenly, place it at 50 °C and stir for 8 h, after the reaction is completed, the system is cooled to room temperature, and then ethanol and water are added to the final reaction solution to The eluent prepared with a volume ratio of 1:3 was used for demulsification and precipitation, and the solid particles were obtained by centrifugation. The solid particles were eluted with ethanol and water with an eluent ...

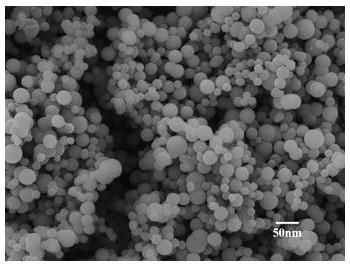

Embodiment 3

[0039] Under anhydrous conditions, take 6.67 g of isomeric tridecanol polyoxyethylene ether and 30 mL of cyclohexane in an oil bath at 50°C, stir magnetically at a rate of 500 rpm for 1 h, then add 2 mL of butanol to form a microemulsion system , then add 0.6mL ethylene glycol and 0.45 mL glacial acetic acid to the microemulsion system, stir well and then add 0.05 g Hβ molecular sieve into it, stir well to obtain a mixed solution, take 0.5mL isopropanol solution (containing 0.25 g isopropanol aluminum propoxide), and then add it to the mixed solution, after mixing evenly, place it at 50°C for constant temperature and stir for 8 h. The eluent prepared at a ratio of 1:4 was used for demulsification and precipitation, and centrifuged to obtain solid particles. The eluent prepared with acetonitrile and water at a volume ratio of 1:4 was used to elute the solid particles, and then centrifuged at 8000 rpm for 30 minutes, and the elution was repeated for 2~ Three times, the separated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com