Method for chemically modifying waterborne wood coatings with nanocellulose dispersed graphene

A technology of nano-cellulose and dispersed graphite, which is applied in cellulose coatings, hemi-cellulose coatings, conductive coatings, etc., and can solve problems such as poor dispersion of nanoparticles and poor mechanical properties of water-based paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

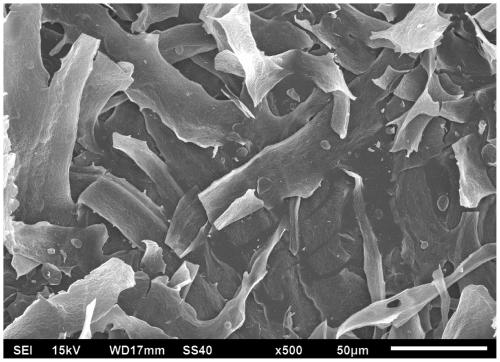

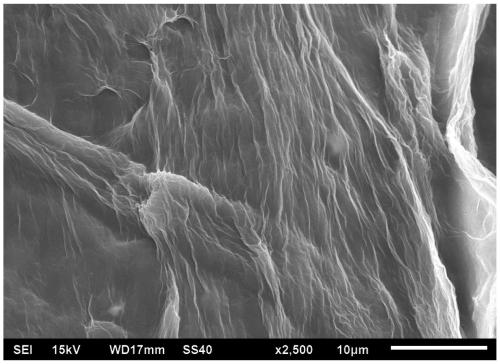

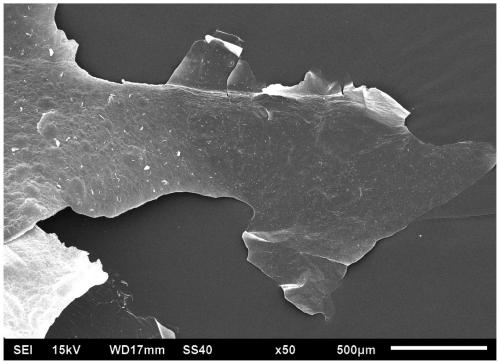

[0053] Specific embodiment one: the method for present embodiment nano-cellulose disperses graphene chemically modified water-based wood coating, comprises the following steps:

[0054] One, the preparation of the nanocellulose aqueous dispersion containing hemicellulose:

[0055] The cellulose raw material is sequentially subjected to extraction treatment and delignification treatment to obtain hemicellulose, and then mechanical pretreatment or chemical mechanical mixing pretreatment is performed to obtain a nanocellulose aqueous dispersion containing hemicellulose;

[0056] Described mechanical pretreatment, concrete operation steps are as follows:

[0057] ① Adding deionized water to the helium cellulose until the mass fraction of the helium cellulose is 0.1% to 0.3%;

[0058] ② Then use a 600bar high-pressure homogeneous mechanical treatment for 30-40 minutes to obtain a nano-cellulose aqueous dispersion containing hemicellulose, wherein the hemicellulose accounts for 20%...

specific Embodiment approach 2

[0075] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the specific steps of the extraction process described in step one are:

[0076] Crush the cellulose raw material into 90-120-mesh powder, and then carry out extraction treatment with benzyl alcohol for 10-12 hours; the benzyl alcohol is a mixture of toluene and absolute ethanol in a volume ratio of 2:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0077] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the specific steps of delignification treatment described in step one are:

[0078] ① Immerse the extracted cellulose powder in a sodium chlorite solution with a mass concentration of 1% to 1.2%, adjust the pH value of the solution to 4 to 5 with glacial acetic acid, and then magnetically place it in a constant temperature water bath at 75 to 80°C. Heat and stir for 1 to 1.5 hours;

[0079] ②Immerse the cellulose powder obtained in step ① into a sodium chlorite solution with a mass concentration of 1% to 1.2%, adjust the pH value of the solution to 4 to 5 with glacial acetic acid, and then magnetically heat it in a constant temperature water bath at 75 to 80°C Stir for 1~1.5h;

[0080] ③ Repeat step ② for 5-6 times to basically remove the lignin, then filter and wash the obtained liquid with a Buchner funnel until the filtrate is neutral, and finally obtain hedophilic cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com