Super-hydrophobic self-cleaning heat-insulating building external wall coating

A technology for thermal insulation, exterior wall coating, applied in building construction, antifouling/underwater coatings, construction, etc., can solve problems such as poor self-cleaning effect, achieve good chemical stability, high optical properties, excellent The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of above-mentioned insulating coating is as follows:

[0045] (1) After mixing pure acrylic elastic emulsion and flexible acrylic emulsion water-based epoxy resin emulsion, add redispersible latex powder, wollastonite powder, water town powder and 2-hydroxyethyl cellulose under high-speed stirring at 3000r / min , adhesion promoter, obtain mixed material A;

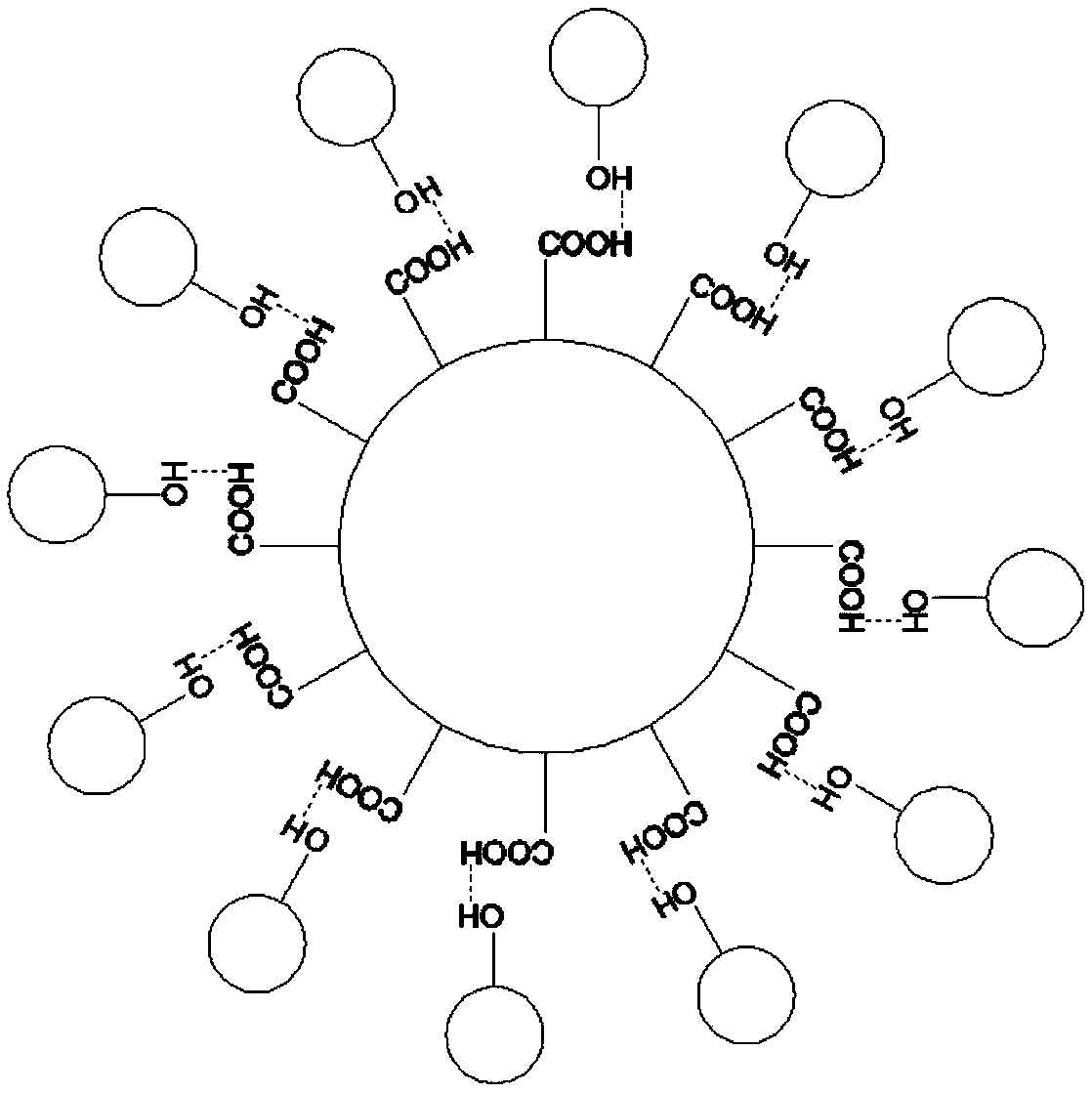

[0046] (2) Add polyacrylic acid hollow spheres into water, add modified nano-ceramic hollow microspheres in batches under high-speed stirring at 2000r / min, and continue high-speed stirring for 30-50min to obtain mixture B;

[0047] (3) Add the mixed material B into the mixed material A, and stir at 2000r / min for 10min to obtain the thermal insulation coating.

[0048] The preparation method of above-mentioned self-cleaning paint is as follows:

[0049] (1) Add dispersant NNO and ammonia water to water, disperse ultrasonically for 30 minutes under high-speed stirring at 2000r / min, then add mod...

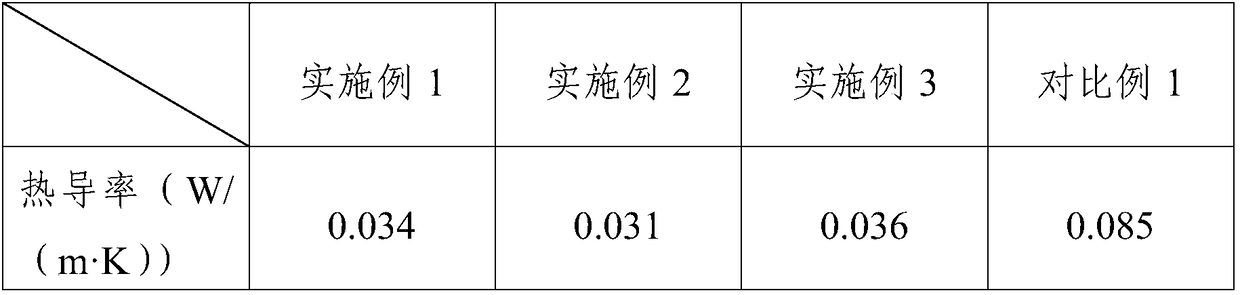

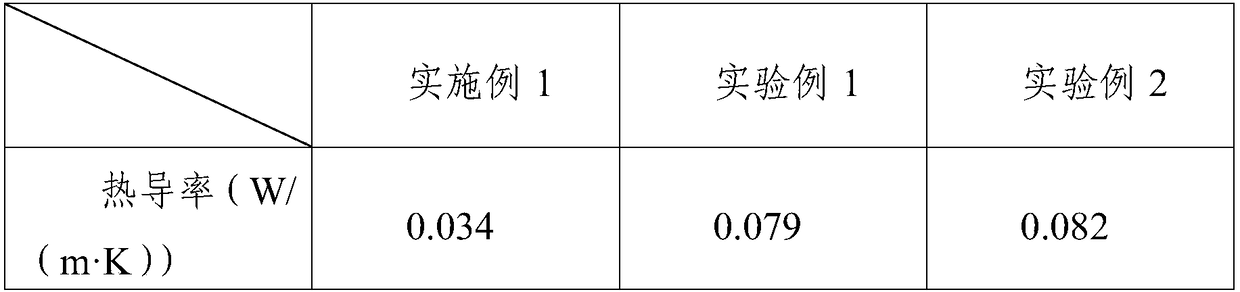

Embodiment 1

[0052] A superhydrophobic self-cleaning thermal insulation building exterior wall coating, comprising a putty layer from inside to outside, thermal insulation coating and self-cleaning coating, the thickness of the putty layer is 5mm, the thickness of thermal insulation coating is 1mm, and the thickness of self-cleaning coating is 0.5mm;

[0053] The thermal insulation coating is composed of component A and component B in a weight ratio of 50:3. Component A includes the following components in parts by weight: 50 parts of pure acrylic elastic emulsion, 40 parts of flexible acrylic emulsion, and 30 parts of water-based epoxy resin emulsion , 15 parts of redispersible latex powder, 15 parts of wollastonite powder, 25 parts of modified nano-ceramic hollow microspheres (with a particle size of 20-50nm), 25 parts of polyacrylic acid hollow spheres (with a particle size of 0.5-5μm), township 4 parts of water powder, 3 parts of 2-hydroxyethyl cellulose, 2 parts of β-(3,4 epoxycyclohex...

Embodiment 2

[0065] A superhydrophobic self-cleaning thermal insulation building exterior wall coating, comprising a putty layer from inside to outside, thermal insulation coating and self-cleaning coating, the thickness of the putty layer is 5mm, the thickness of thermal insulation coating is 1mm, and the thickness of self-cleaning coating is 0.5mm;

[0066] The thermal insulation coating is composed of component A and component B at a weight ratio of 50:1. Component A includes the following components in parts by weight: 40 parts of pure acrylic elastic emulsion, 30 parts of flexible acrylic emulsion, and 20 parts of water-based epoxy resin emulsion , 10 parts of redispersible latex powder, 10 parts of wollastonite powder, 20 parts of modified nano-ceramic hollow microspheres (with a particle size of 20-50nm), 20 parts of polyacrylic acid hollow spheres (with a particle size of 0.5-5μm), township 1 part of water powder, 1 part of 2-hydroxyethyl cellulose, 1 part of γ-mercaptopropyltrimeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com