Tin-antimony oxide nanoparticles with peroxidase-like characteristic and preparation method and application thereof

An antimony tin oxide, nanoparticle technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of large-scale use, decreased HRP activity, and reaction conditions. Advanced problems, to achieve the effect of high yield, simple preparation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

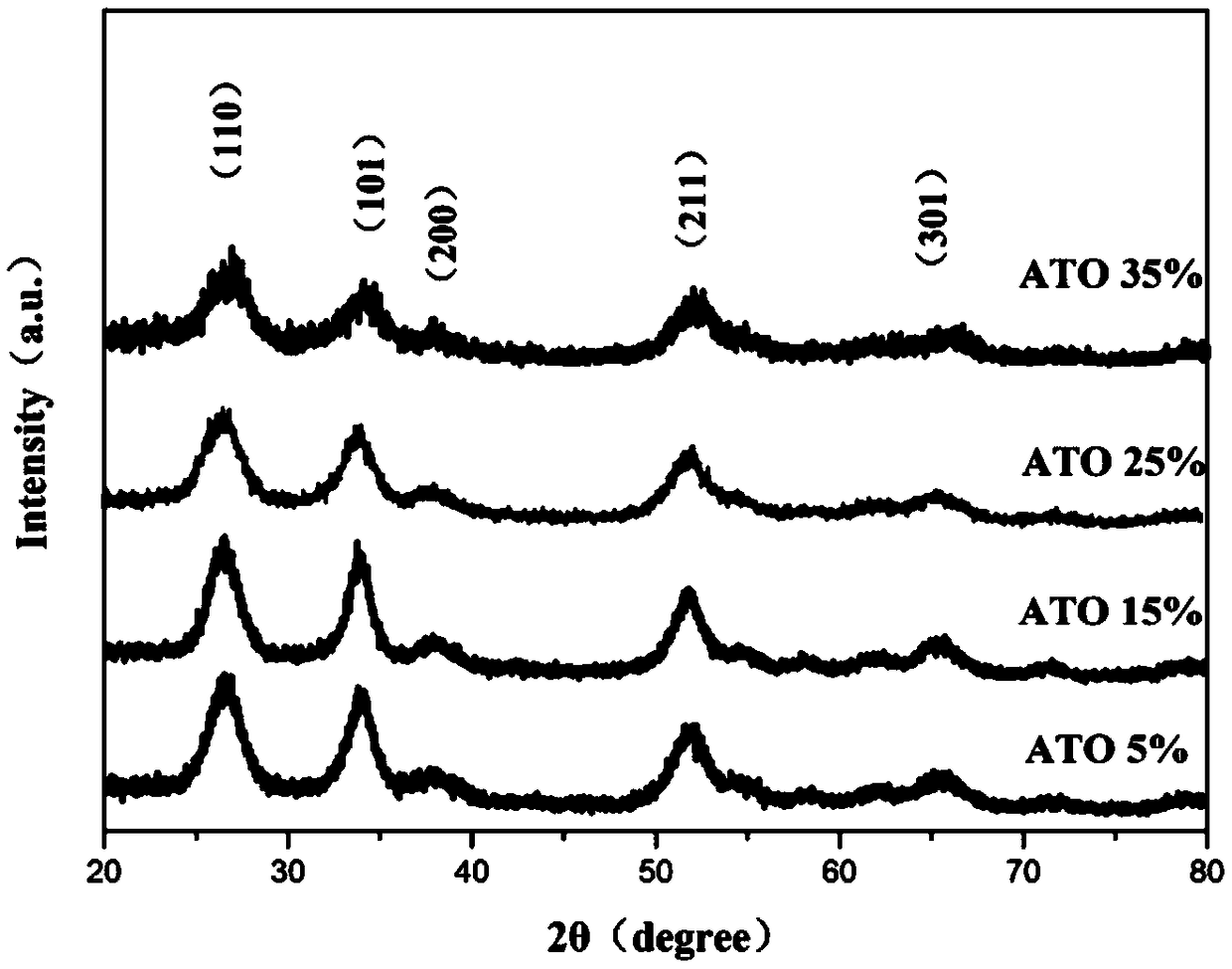

Embodiment 1

[0028] Weigh 1g of tin particles and 0.44g of antimony trioxide powder into a 100mL three-necked flask, and add 8mL of concentrated sulfuric acid. Then the mixed solution was magnetically stirred and heated at 95° C. for 10 hours. After the heating was completed, the solution was mixed in an ice-water bath, and 32 mL of hydrogen peroxide was slowly added dropwise. After 20 minutes, 24 mL of ultrapure water was added under the condition of magnetic stirring, and stirred for 20 minutes. Finally, the mixed solution was transferred to a 100 mL autoclave, and reacted in an oven at 160° C. for 10 hours. After the reaction, the mixed liquid was centrifuged (rotating speed 5500rpm, 5 minutes), and the precipitate was washed 3 times with ultra-pure water, then 1 time with ethanol, dried, and ground into powder to obtain 35% antimony-doped oxidation Tin-antimony nanopowder, sealed and preserved for future use.

Embodiment 2

[0030] Weigh 1g of tin particles and 0.31g of antimony trioxide powder into a 100mL three-necked flask, and add 8mL of concentrated sulfuric acid. Then the mixed solution was magnetically stirred and heated at 95° C. for 10 hours. After the heating was completed, the solution was mixed in an ice-water bath, and 32 mL of hydrogen peroxide was slowly added dropwise. After 20 minutes, 24 mL of ultrapure water was added under the condition of magnetic stirring, and stirred for 20 minutes. Finally, the mixed solution was transferred to a 100 mL autoclave, and reacted in an oven at 160° C. for 10 hours. After the reaction is over, centrifuge the mixed liquid (5500 rpm for 5 minutes), take the precipitate, wash it with ultrapure water for 3 times, then wash it with ethanol once, dry it, and grind it into powder to obtain tin oxide with 25% antimony doping Antimony nanopowder, sealed for future use.

Embodiment 3

[0032] Weigh 1g of tin particles and 0.18g of antimony trioxide powder into a 100mL three-necked flask, and add 8mL of concentrated sulfuric acid. Then the mixed solution was magnetically stirred and heated at 95° C. for 10 hours. After the heating was completed, the solution was mixed in an ice-water bath, and 32 mL of hydrogen peroxide was slowly added dropwise. After 20 minutes, 24 mL of ultrapure water was added under the condition of magnetic stirring, and stirred for 20 minutes. Finally, the mixed solution was transferred to a 100 mL autoclave, and reacted in an oven at 160° C. for 10 hours. After the reaction, the mixed liquid was centrifuged (rotating speed 5500rpm, 5 minutes), and the precipitate was washed 3 times with ultrapure water, then 1 time with ethanol, dried, and ground into powder to obtain 15% antimony-doped oxidation Tin-antimony nanopowder, sealed and preserved for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com