Method for efficiently recovering iron, scandium and aluminum from limonite type lateritic nickel ores

A technology for recovering iron from laterite nickel ore, which is applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of low metal recovery rate, high production cost, high equipment requirements, etc., and is beneficial to iron enrichment, simple and effective separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

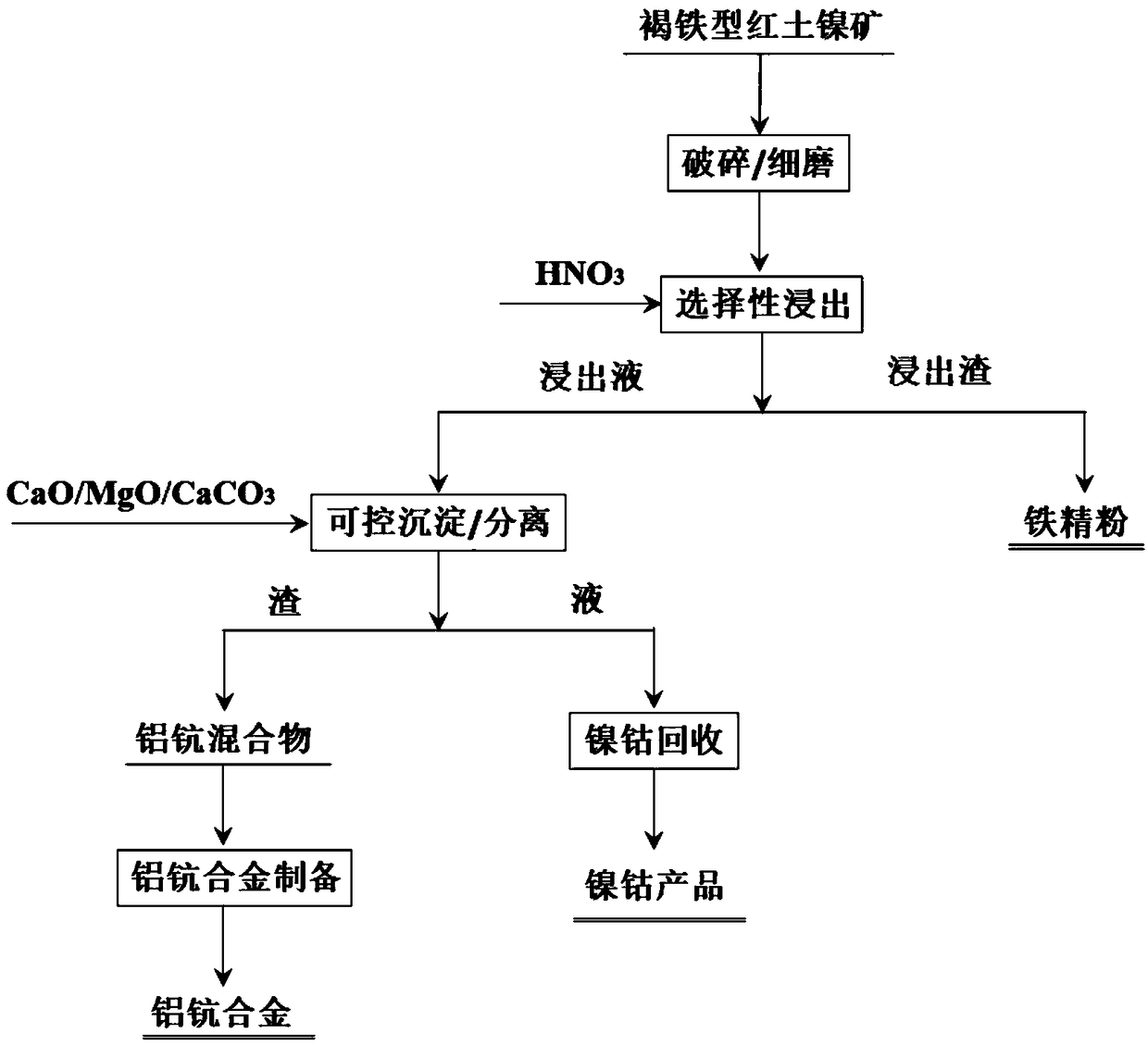

[0036] Such as figure 1As shown, a method for efficiently recovering iron, scandium and aluminum from limonite-type laterite-nickel ore includes: taking 2 tons of limonite-type laterite-nickel ore for crushing / fine grinding, so that the ore in the ore powder has a particle size of less than 74 μm Accounting for 100% of the total weight of the crushed / finely ground ore. Take an appropriate amount of mineral powder, add nitric acid with an initial acidity of 300g / L to the mixture, under the conditions of leaching temperature of 180°C, leaching time of 1h, liquid-solid ratio of 1:1g / mL, and stirring speed of 500rpm , to carry out selective leaching to obtain iron concentrate with an iron content of 60%; the leaching solution is subjected to controlled precipitation / separation operation, and the pH is controlled to 4.3 by adding calcium oxide, the precipitation temperature is 50°C, the precipitation time is 2h, and the stirring speed is 200rpm The aluminum-scandium mixture is obt...

Embodiment 2

[0038] A method for efficiently recovering iron, scandium and aluminum from limonite-type laterite-nickel ore, comprising: taking 2 tons of limonite-type laterite-nickel ore ore for crushing / fine grinding, so that the ore with a particle size of less than 74 μm in the ore powder accounts for the 80% of the total weight of ore after crushing / fine grinding. Take an appropriate amount of mineral powder, add nitric acid with an initial acidity of 300g / L to the mixture, and leaching at a temperature of 150°C, a leaching time of 2 hours, a liquid-solid ratio of 1:3g / mL, and a stirring speed of 600rpm. , to carry out selective leaching to obtain iron concentrate with an iron content of 61%; the leaching solution is subjected to controllable precipitation / separation operation, the pH is controlled to 4.2 by adding magnesium oxide, the precipitation temperature is 80°C, the precipitation time is 1h, and the stirring speed is 150rpm The aluminum-scandium mixture is obtained. After the a...

Embodiment 3

[0040] A method for efficiently recovering iron, scandium and aluminum from limonite-type laterite-nickel ore, comprising: taking 2t of limonite-type laterite-nickel ore ore for crushing / fine grinding, so that the ore with a particle size of less than 74 μm in the ore powder accounts for the 70% of the total weight of ore after crushing / fine grinding. Take an appropriate amount of mineral powder, add nitric acid with an initial acidity of 200g / L to the mixture, under the conditions of a leaching temperature of 200°C, a leaching time of 0.5h, a liquid-solid ratio of 1:5g / mL, and a stirring speed of 300rpm Selective leaching was carried out to obtain iron concentrate with an iron content of 60%; the leaching solution was subjected to controlled precipitation / separation operation, and the pH was controlled to 4.0 by adding calcium carbonate, the precipitation temperature was 30°C, the precipitation time was 3 hours, and the stirring speed was 150rpm to obtain an aluminum-scandium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com