High-emulsification-performance yolk powder liable to be dispersed and preparation method thereof

A technology of emulsification and egg yolk powder, which is applied in the direction of food ingredients as antioxidants, food ingredients as pH value modifiers, food ingredients, etc., can solve the problems of low rehydration rate, easy oxidation, and low emulsification of egg yolk powder. Achieve the effect of reducing direct denaturation or aggregation of egg yolk, improving dispersion and strong emulsifying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

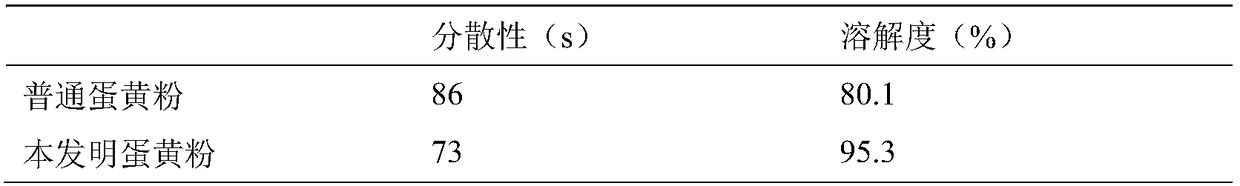

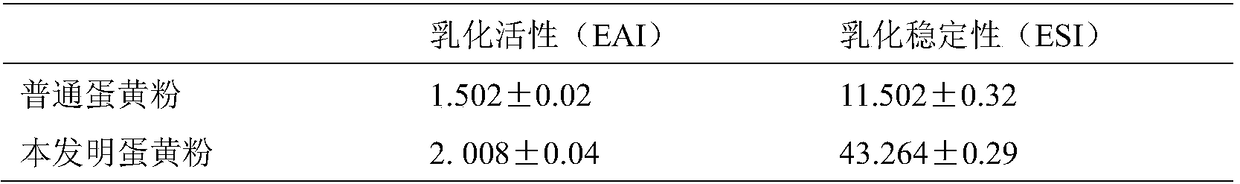

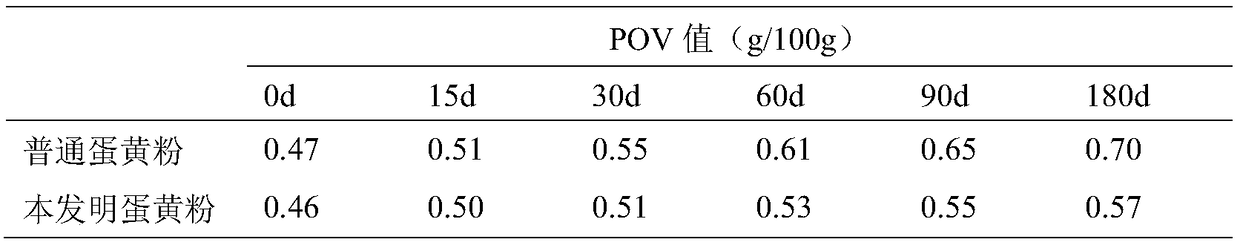

[0039] Purchase 10kg of fresh poultry eggs, wash and disinfect, dry the surface moisture, carefully crack the shell, separate the egg white and egg yolk, collect the egg yolk liquid, stir at room temperature at a stirring speed of 200r / min, filter and remove impurities, and obtain a uniform, impurity-free egg yolk liquid . Then, the egg yolk liquid was processed by ultrasonic wave, and the process was performed for 30 min under the conditions of ultrasonic frequency 20 kHz and output power 600 W. Then, use disodium hydrogen phosphate / sodium dihydrogen phosphate to adjust the pH value of the egg yolk liquid to 7.5-8.0, add phospholipase A1 to the egg liquid, the addition amount is 0.1% (w / w) of the yellow liquid mass, at 28 ℃ Under the condition of hydrolysis reaction 120min. Put maltodextrin, lecithin, potassium sorbate, and calcium lactate into egg yolk hydrolyzate, the addition amount is 3.0%, and the ratio of maltodextrin, lecithin, calcium lactate, and potassium sorbate i...

Embodiment 2

[0041] Purchase 10kg of fresh poultry eggs, wash and disinfect, dry the surface moisture, carefully crack the shell, separate the egg white and egg yolk, collect the egg yolk liquid, stir at room temperature at a stirring speed of 200r / min, filter and remove impurities, and obtain a uniform, impurity-free egg yolk liquid . Then, the egg yolk liquid was treated with ultrasonic waves, and the ultrasonic frequency was 30 kHz, and the output power was 500 W for 20 min. Then, use calcium dihydrogen phosphate / tricalcium phosphate to adjust the pH value of the egg yolk liquid to 8.5-9.0, add phospholipase A2 to the egg liquid, the addition amount is 0.1% (w / w) of the yellow liquid mass, at 28 ° C Under the hydrolysis reaction 150min. Put cyclodextrin, lecithin, potassium sorbate, and calcium lactate into the egg yolk hydrolyzate, the addition amount is 4.0%, and the ratio of lecithin, calcium lactate, and potassium sorbate is 5:2:2:1. Then perform phacoemulsification treatment for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com