Preparation method and oil-water separation membrane of high-strength and high-flux oil-water separation membrane

An oil-water separation membrane and high-throughput technology, which is applied in the preparation of oil-water separation membranes and the preparation of oil-water separation membranes, can solve the problems of poor mechanical properties of electrospun membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Experimental Materials:

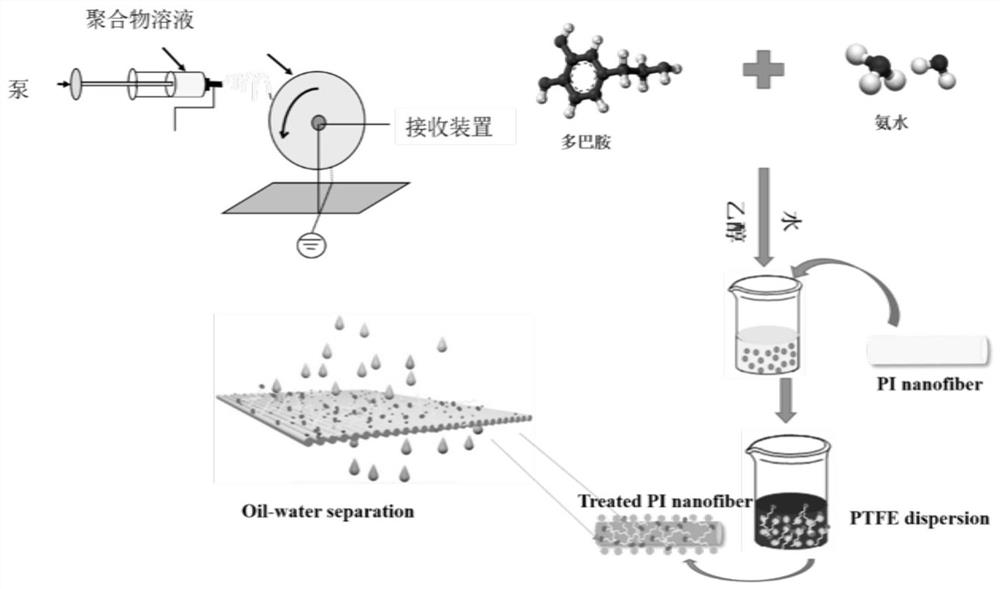

[0037] p-Phenylenediamine, 3,3′, 4,4′biphenyltetracarboxylic dianhydride (BPDA), N,N-dimethylacetamide (DMAC), dichloromethane (DCM), chloroform, tetrachloromethane Carbon dioxide and other solution solvents, cetyltrimethylammonium bromide (CTAB) and dopamine hydrochloride (PDA) and aqueous polytetrafluoroethylene (PTFE) dispersion (solid content is 60%).

[0038] Preparation process of oil-water separation membrane:

[0039] Polyamic acid synthesis:

[0040] Preparation of polyamic acid (PAA) by low-temperature ring-opening addition polymerization: BPDA (2.9422g, 0.01mol), p-phenylenediamine (1.0814g, 0.01mol) and 40mLDMAc were added to a three-necked flask at the same time, and the temperature was reduced to minus 5 in a nitrogen atmosphere. Under the environment of degree Celsius, the reaction was completed after 24 hours of reaction, and the molecular weight distribution of polyamic acid was measured by gel permeation chromatography.

[...

Embodiment 2

[0046] Oil-water separation test:

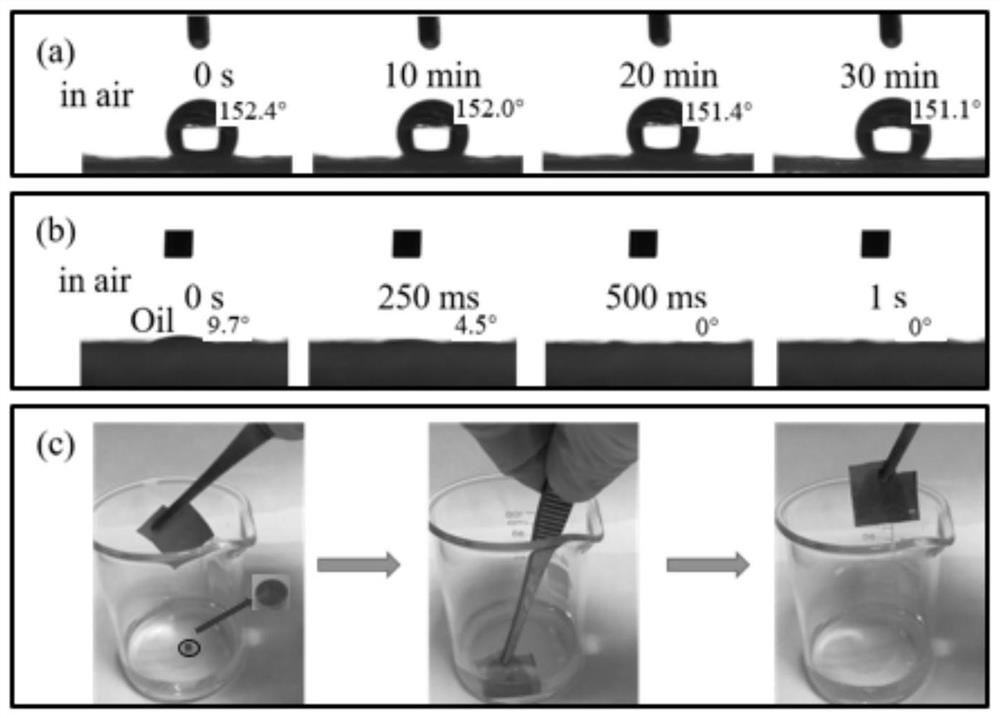

[0047] (1) Measure 10 mL of dichloromethane and water respectively, wherein the dichloromethane is dyed with oil red, and the water is dyed blue with methylene blue. After the oil-water mixture solution was left to stand for 1 min, the oil-water separation occurred. The water dyed blue is on the upper layer, the red oil is on the lower layer, and the PDA / PTFE-PI nanofiber membrane is fixed between two glass tubes. Then pour the layered mixed solution into the upper glass tube for oil-water separation. The red water is as fast as permeating through the PDA / PTFE-PI nanofiber membrane and flows into the beaker below, while the blue water remains in the upper glass tube, and the time when the oil and water are completely separated and the time before and after the separation are measured. volume of water, such as Figure 4 .

[0048] (2) Select different oil-water mixtures (dichloromethane-water, bromobenzene-water, carbon tetrachloride-wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com