Carbon-based adsorbent and preparation method thereof

An adsorbent, carbon-based technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of poor adsorption performance, single element type, etc., achieve easy recovery, wide pH range, The effect of excellent adsorption activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 100mg SiO 2 Evenly dispersed in 100mL of methanol, ultrasonic 10min. Dissolve 300mg of hexachlorotripolyphosphazene and 600mg of bisphenol S in 10mL of methanol solution, add dropwise to the ultrasonically dispersed silica suspension, and stir for 5 minutes; add 0.6mL of triethylamine dropwise to the above suspension, and stir 1 hour. The resulting product was washed three times with methanol and dried under vacuum at 60°C. The obtained product was carbonized at 400° C. under an argon atmosphere at a heating rate of 2° C. / min. Then, it was etched in 0.5 mol / L sodium hydroxide solution for 2 hours, and the product was washed with desalted water until neutral, and dried in vacuum at 60°C.

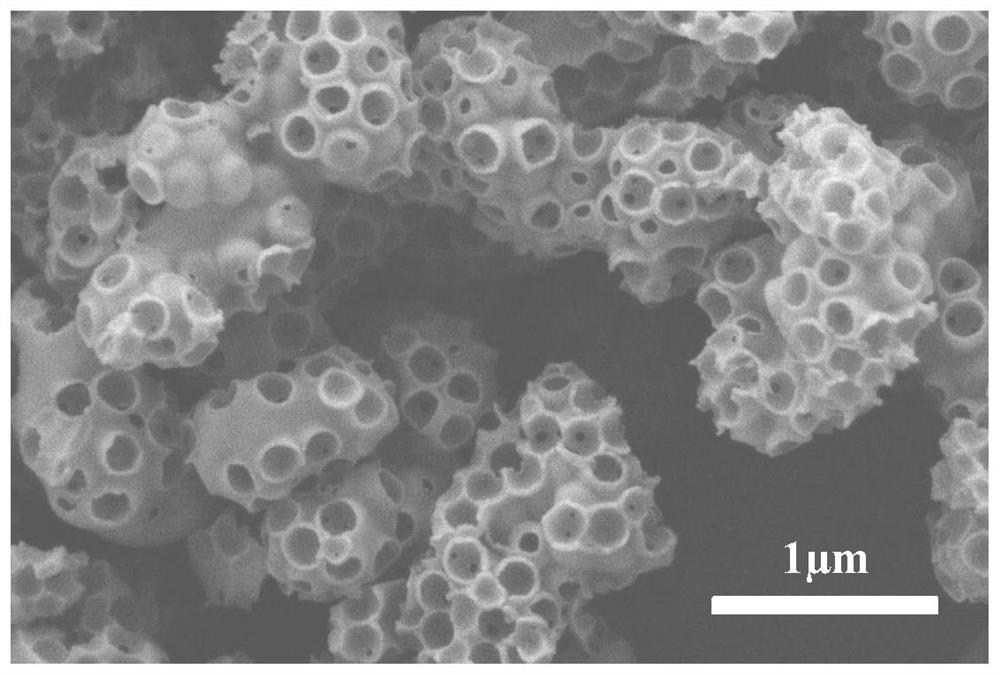

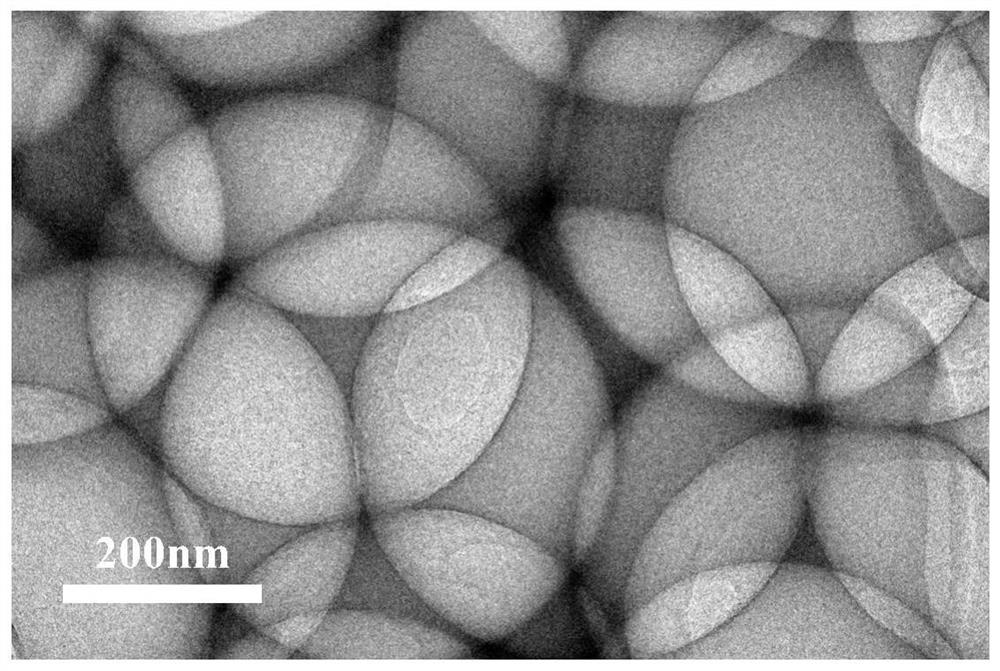

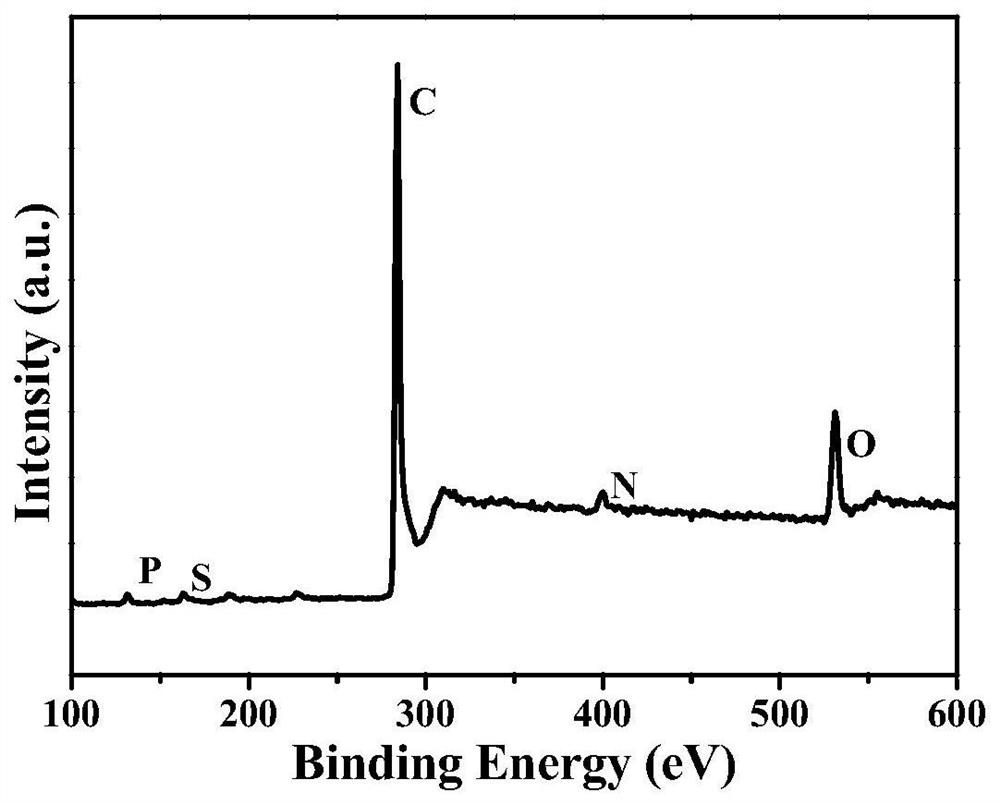

[0038] Such as figure 1 , figure 2 As shown, after removing the silica template by etching, it can be clearly seen that the adsorbent presents a three-dimensional inverse opal-type framework structure. image 3 It is the X-ray photoelectron spectroscopy (XPS) analysis of the ads...

Embodiment 2

[0042] 200mg SiO 2 Evenly dispersed in 100mL ethanol, ultrasonic 15min. Dissolve 300mg of hexachlorotripolyphosphazene and 1000mg of bisphenol S in 50mL of methanol solution, add dropwise to the ultrasonically dispersed silica suspension, and stir for 10min; add 0.9mL of triethylamine dropwise to the above suspension, and stir 3 hours. The resulting product was washed three times with methanol and dried under vacuum at 60°C. The obtained product was carbonized at 500° C. under an argon atmosphere at a heating rate of 3° C. / min. Then, it was etched in 5.0 mol / L sodium hydroxide solution for 6 hours, and the product was washed with desalted water until it was neutral, and dried in vacuum at 60°C.

Embodiment 3

[0044] 300mg SiO 2 Evenly dispersed in 100mL of methanol, ultrasonic 20min. Dissolve 300mg of hexachlorotripolyphosphazene and 1500mg of bisphenol S in 100mL of methanol solution, add dropwise the ultrasonically dispersed silica suspension, and stir for 15 minutes; add 1.2mL of triethylamine dropwise to the above suspension, and stir 5 hours. The resulting product was washed three times with methanol and dried under vacuum at 60°C. The obtained product was carbonized at 600° C. under a nitrogen atmosphere at a heating rate of 5° C. / min. Then, it was etched in 0.5 mol / L potassium hydroxide solution for 10 hours, and the product was washed with desalted water to neutrality, and dried in vacuum at 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com