Sulfur carbon sphere-supported noble metal catalyst and its preparation and application in synthesis of N, N'-dibenzylethylenediamine

A precious metal catalyst and catalyst technology, which is applied in the preparation of amino compounds, the preparation of organic compounds, catalysts for physical/chemical processes, etc. Complex steps and other problems, to achieve the effect of being beneficial to industrial application, excellent catalytic performance, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

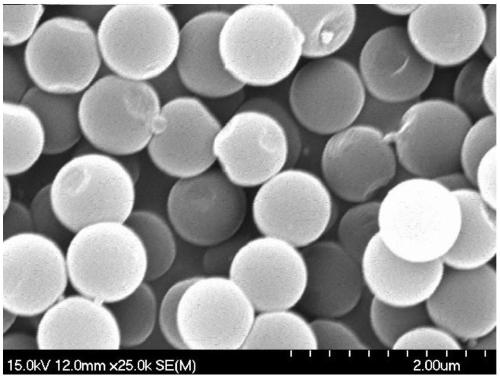

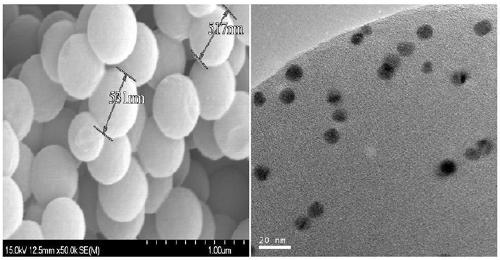

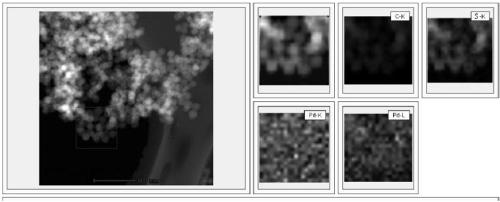

Embodiment 1

[0040] Take 100ml of deionized water in a three-necked flask, install a condensation reflux device in one port, and seal the other two ports with glass stoppers; then add 0.5g cetyltrimethylammonium bromide and 1.5g cysteine solid, set The temperature of the water bath was 30°C, and magnetic stirring was started for 1 h until the solid was completely dissolved. Subsequently, add 5 g of 4,4'-thiodisalicylic acid thiophenol solid, continue to stir for 0.5 h until the solid is completely dissolved, then open one of the glass stoppers, and slowly add 2 ml of concentrated H 2 SO 4 The solution is in the above mixed solution, and the rate of addition is strictly controlled to prevent the temperature rise caused by the heat of dissolution from exceeding 2°C. Continue magnetic stirring, from room temperature to 60°C at a heating rate of 0.1°C / min, keep for 6h, then continue to rise to 90°C at a heating rate of 0.1°C / min, keep for 6h, and finally continue to rise to boiling at a hea...

Embodiment 2

[0044] Take 100ml of deionized water in a three-necked flask, install a condensation reflux device in one port, and seal the other two ports with glass stoppers; then add 1g of cetyltrimethylammonium bromide and 2g of cysteine solid, and set the temperature of the water bath At 30°C, start magnetic stirring for 1 h until the solid is completely dissolved. Subsequently, 8 g of 4,4'-thiodisalicylic acid thiophenol solid was added, and stirring was continued for 0.5 h until the solid was completely dissolved, then one of the glass stoppers was opened, and 2 ml of concentrated H 2 SO 4 The solution is in the above mixed solution, and the rate of addition is strictly controlled to prevent the temperature rise caused by the heat of dissolution from exceeding 2°C. Continue magnetic stirring, from room temperature to 60°C at a heating rate of 0.1°C / min, keep for 8h, then continue to rise to 90°C at a heating rate of 0.1°C / min, keep for 8h, and finally continue to rise at a heating ...

Embodiment 3

[0048] Take 100ml of deionized water in a three-necked flask, install a condensation reflux device in one port, and seal the other two ports with glass stoppers; then add 1g of cetyltrimethylammonium bromide and 2g of cysteine solid, and set the temperature of the water bath At 30°C, start magnetic stirring for 1 h until the solid is completely dissolved. Subsequently, add 10 g of 4,4'-thiodisalicylic acid thiophenol solid, continue to stir for 0.5 h until the solid is completely dissolved, then open one of the glass stoppers, and slowly add 2 ml of concentrated H 2 SO 4 The solution is in the above mixed solution, and the rate of addition is strictly controlled to prevent the temperature rise caused by the heat of dissolution from exceeding 2°C. Continue magnetic stirring, raise the temperature from room temperature to 60°C at a rate of 1°C / min, keep for 12 hours, then continue to increase the rate of temperature at 1°C / min to 90°C, keep for 12 hours, and finally continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com