High-barrier graphene masterbatch for degradable packaging plastic and preparation method thereof

A technology for packaging plastics and graphene, applied in the field of high-barrier graphene masterbatch and preparation, can solve the problems of serious agglomeration, secondary agglomeration, poor dispersion, etc., reduce the probability of secondary agglomeration, improve barrier performance, and tightly bonded Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

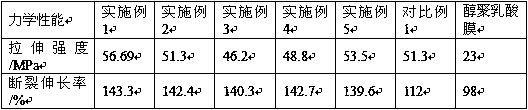

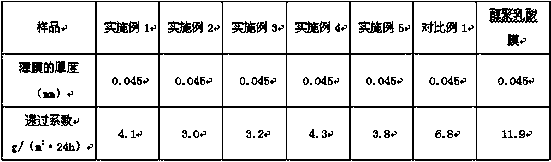

Examples

Embodiment 1

[0028] The preparation of a high-barrier graphene master batch for degradable packaging plastics of the present invention comprises the following steps:

[0029]a. Add graphene into organic solvent, stir and disperse, add acrylic acid monomer, initiator, reducing agent, adjust the pH value of the solution to 7, react under nitrogen environment, generate polyacrylic acid as anion polyelectrolyte to modify graphene, filter, Obtain the graphene of the polyacrylic acid modification of negative charge; Described organic solvent is NMP; The mass ratio of described graphene, organic solvent, acrylic acid monomer is 12:30:25; Described initiator is ammonium persulfate; Described Reducing agent is sodium borohydride; The mass ratio of described acrylic acid monomer, initiator, reducing agent is 8:5:9;

[0030] b, the negatively charged polyacrylic acid-modified graphene obtained in step a is formulated into a negatively charged PAA-graphene dispersion, calcium aluminum hydrotalcite is ...

Embodiment 2

[0033] The preparation of a high-barrier graphene master batch for degradable packaging plastics of the present invention comprises the following steps:

[0034] a. Add graphene into organic solvent, stir and disperse, add acrylic acid monomer, initiator, reducing agent, adjust the pH value of the solution to 8, react under nitrogen environment, generate polyacrylic acid as anion polyelectrolyte to modify graphene, filter, Obtain the graphene of the polyacrylic acid modification of negative charge; Described organic solvent is DMF; The mass ratio of described graphene, organic solvent, acrylic acid monomer is 6:27:30; Described initiator is reducing agent sodium bisulfite ; The reducing agent is lithium aluminum hydride; The mass ratio of the acrylic acid monomer, initiator, and reducing agent is 10:7:10;

[0035] b, the negatively charged polyacrylic acid-modified graphene obtained in step a is formulated into a negatively charged PAA-graphene dispersion, calcium aluminum hyd...

Embodiment 3

[0038] The preparation of a high-barrier graphene master batch for degradable packaging plastics of the present invention comprises the following steps:

[0039] a. Add graphene into organic solvent, stir and disperse, add acrylic acid monomer, initiator, reducing agent, adjust the pH value of the solution to 7.5, react under nitrogen environment, generate polyacrylic acid as anion polyelectrolyte to modify graphene, filter, Obtain the graphene of negatively charged polyacrylic acid modification; Described organic solvent is NMP; The mass ratio of described graphene, organic solvent, acrylic acid monomer is 10:40:25; Described initiator is azobisisobutyronitrile ; The reducing agent is hydrazine hydrate; the mass ratio of the acrylic acid monomer, initiator, and reducing agent is 7:4:11;

[0040] b, the negatively charged polyacrylic acid-modified graphene obtained in step a is formulated into a negatively charged PAA-graphene dispersion, calcium aluminum hydrotalcite is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com