A treatment process and complete set of equipment for near-zero emission of waste tire pyrolysis waste gas pollution

A waste tire, near-zero emission technology, used in gas treatment, lighting and heating equipment, petroleum industry and other directions, can solve the problems of slow cooling of high-temperature flue gas, existing problems in treatment, and no treatment and purification, shortening the residence time and suppressing low temperature. The effect of resynthesis and suppression of high temperature generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

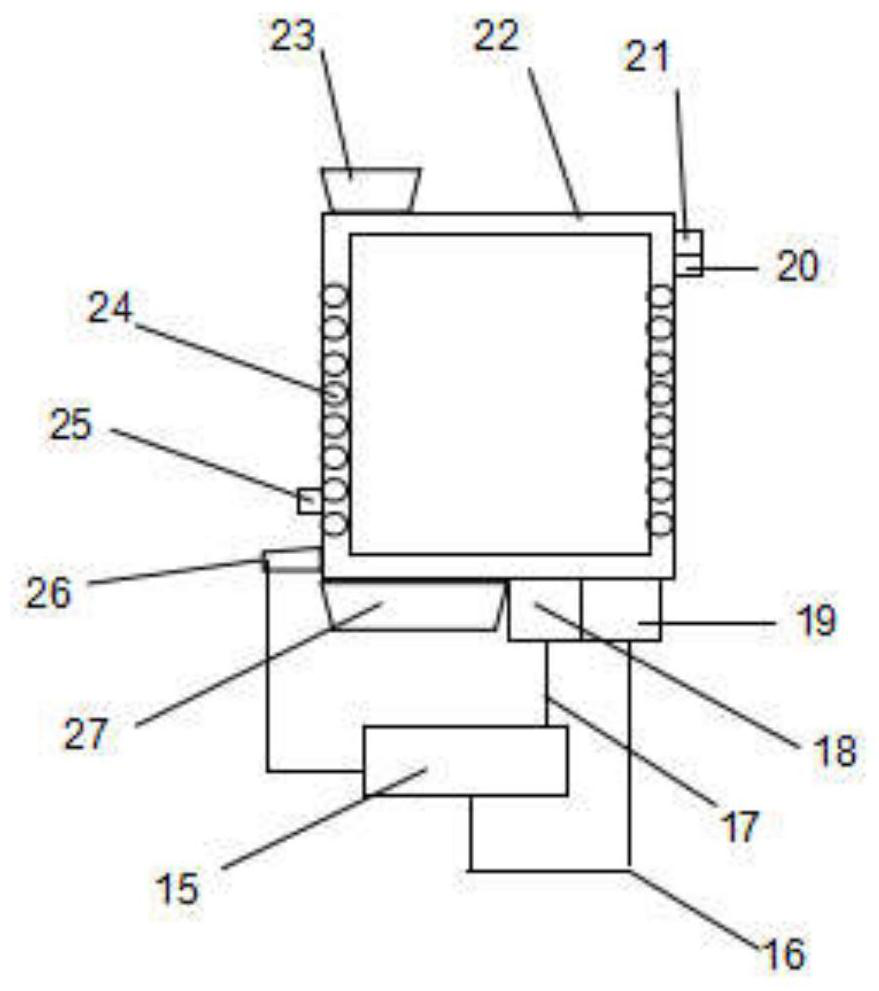

[0032] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

[0033] The ammonia water-lime circulation spraying device described in the embodiment of the present invention can adopt various ammonia water-lime desulfurization and denitrification devices in the field, and the high pressure in the high-pressure steel pipe adopts an air compressor to realize high pressure, thereby achieving ammonia water, Lime can be ejected from the rotary nozzle 11 under high pressure.

[0034] The Venturi scrubber, cyclone separator, bag filter, and condensing oil and gas recovery device described in the embodiments of the present invention are products of the prior art.

[0035] The rotary scraper described in the embodiment of the present invention can be a four-bladed rotary scraper, or various conventional rotary scrapers in the field.

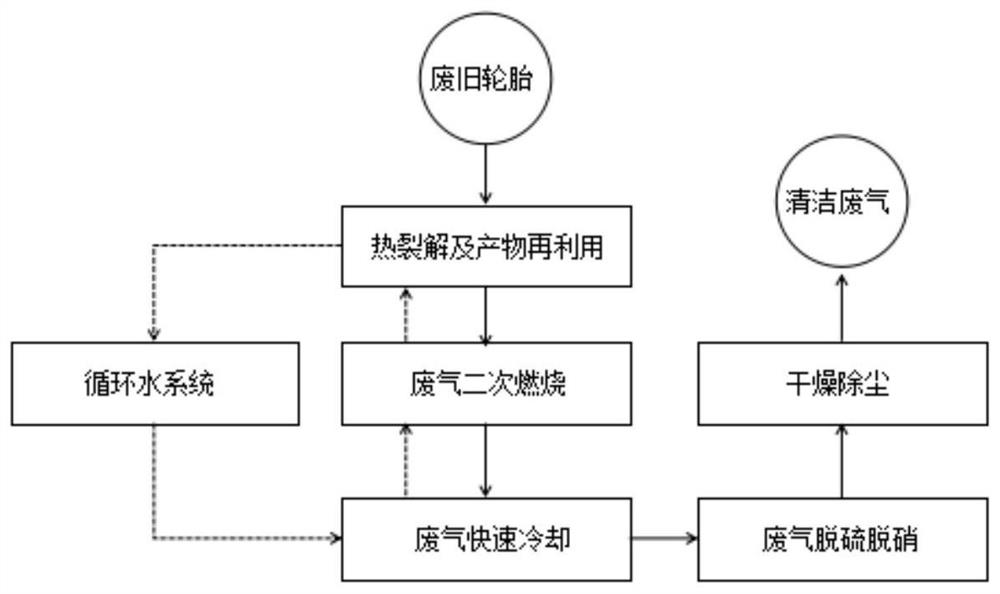

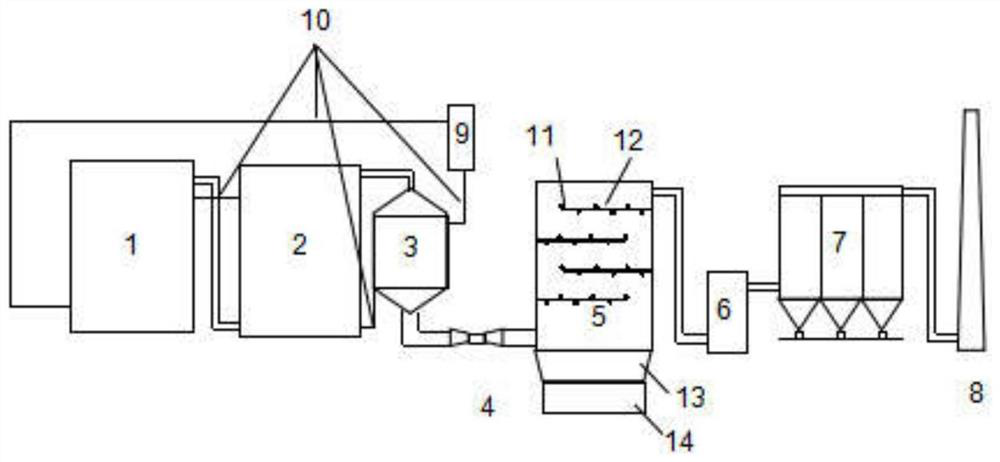

[0036] Such as figure 1 , figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com