Preparation method of Clostridium butyricum powder

A technology of Clostridium butyricum and bacteria powder is applied in the directions of microorganism-based methods, biochemical equipment and methods, bacteria, etc., to achieve the effects of good stability, strong process controllability and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

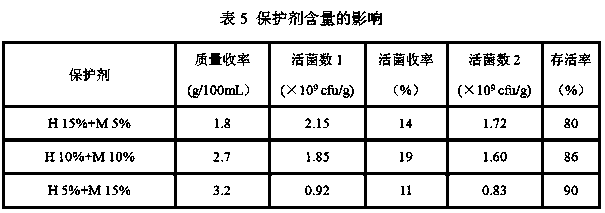

[0025] Embodiment 1 Influence of inlet temperature

[0026] Adjust the inlet temperature of the spray drying, spray and dry the untreated Clostridium butyricum fermentation broth directly, the number of live bacteria in the original bacterial liquid is 5.7×10 8 cfu / mL, the ferric sulfite plate counting method was used for the obtained bacterial powder (the plate counting method is also used in the following), and the plate counting was performed again after 10 days at 40°C. The results are shown in Table 1:

[0027] Table 1 Effect of inlet temperature

[0028]

[0029] Note: The number of viable bacteria 1 is the number of viable bacteria obtained by the instant detection of the bacteria powder obtained by spray drying, that is, the number of viable bacteria; the number of viable bacteria 2 is the number of viable bacteria after being placed at 40ºC for 10 days; the number of viable bacteria 3 is the number of viable bacteria after being placed at room temperature for 3 m...

Embodiment 2

[0030] Embodiment 2 Bacterial liquid carries out the impact of centrifugation pretreatment

[0031] Take 100 mL of Clostridium butyricum fermentation broth, centrifuge at 4000 rpm for 10 min, take the sludge, and then reduce it with an equal volume of sterile water, add 20% sodium alginate to the treated bacterial suspension; ferment with 100 mL 20% sodium alginate was directly added to the solution as a control, and the number of viable bacteria and stability of the spray-dried bacteria powder were compared. The inlet temperature of the nebulizer during spray drying was 180ºC.

[0032] Three batches of fermentation broth were tested at the same time, and the number of viable bacteria in batch 1 was 7.2×10 8 cfu / mL, the number of viable bacteria in batch 2 is 5.7×10 8 cfu / mL batch, the number of viable bacteria in batch 3 is 2.7×10 8 cfu / mL. The results are shown in Table 2:

[0033]

[0034] Note: The number of viable bacteria 1 is the number of viable bacteria imm...

Embodiment 3

[0036] Embodiment 3 The influence of centrifugation condition

[0037] Take 10 mL of fermentation broth, centrifuge under the different conditions in Table 3, discard the supernatant, add sterile water to 10 mL, and measure the number of viable bacteria in the bacterial suspension after mixing. The results are shown in Table 3 :

[0038]

[0039] The results showed that when the rotational speed was 4000 rpm and the centrifugation time was 10 min, the residual amount of viable bacteria in the sludge was the highest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com