A method for measuring the water content of triethylene glycol dinitrate and nitroglycerin mixed nitrate by hydrogen nuclear magnetic resonance

A technology of triethylene glycol dinitrate and proton nuclear magnetic resonance spectroscopy, which is applied in the fields of analysis by nuclear magnetic resonance, material analysis by resonance, and measuring devices, which can solve the limitations of high cost, simple and rapid quantitative analysis work. , cumbersome methods and other problems, to achieve the effect of simple and rapid testing, high sensitivity, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

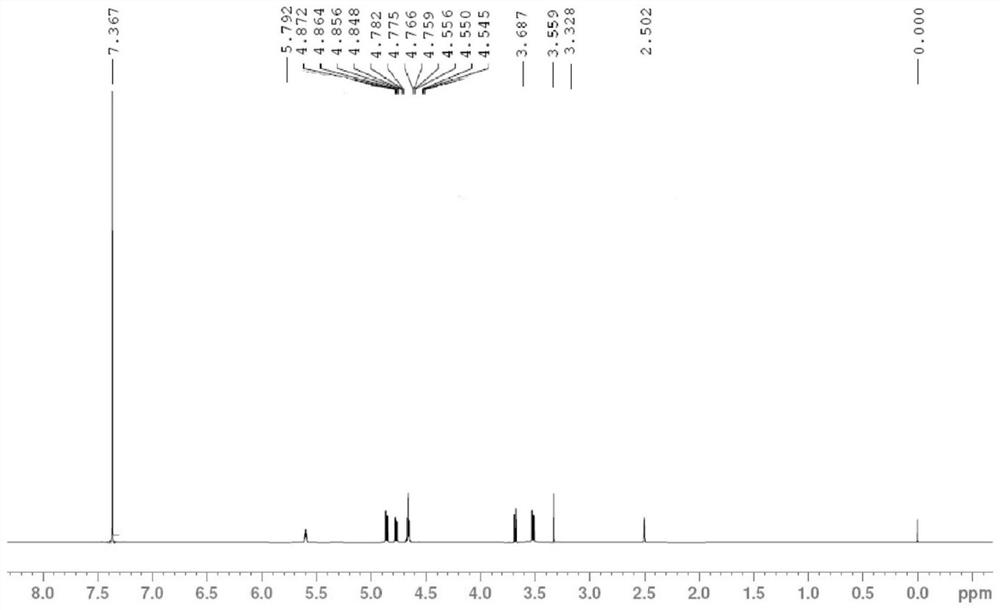

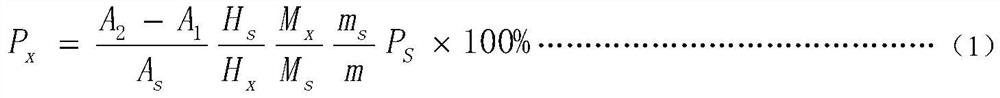

[0030] TEGDN / NG mixed nitrate 1 Construction of H NMR spectrum

[0031] 1.1 Instruments and samples

[0032] BrukerAscend 800 superconducting nuclear magnetic resonance spectrometer (German BRUKER company); MettlerToledoXP6 type one hundred thousandth balance (Switzerland METTLER company); deuterated dimethyl sulfoxide (deuterated degree > 99.8%, American CIL company); 5mm Standard NMR sample tube (NORELL, USA); Benzene purity standard substance (Tianjin Metrology Supervision and Testing Science Research Institute, batch number 0401); TEGDN / NG mixed nitrate (Xi’an Institute of Modern Chemistry, batch number 170903)

[0033] 1.2 Preparation and determination of samples to be tested

[0034] Accurately weigh 5-15mg of the internal standard benzene standard substance into a 5mm NMR tube, then add 0.6ml of deuterated dimethyl sulfoxide, mix well and seal it with a parafilm, and use the prepared NMR sample directly for 1 H NMR test. After the test is over, remove the NMR sample...

Embodiment 2

[0051] Determination of water content in different batches of TEGDN / NG mixed nitrate by 1H NMR

[0052] Accurately weigh 5.3mg of internal standard benzene into a 5mm NMR tube, then add 0.6ml deuterated dimethyl sulfoxide, mix well and seal with a parafilm, and use the prepared NMR sample directly for 1 H NMR test, test parameters and conditions are: observation frequency 800.3MHz, measurement temperature 300K, 90° pulse, spectrum width 3μs, sampling data points 65536, scan times 128 times, delay time 30s. Then remove the NMR sample tube after the test, add 15 mg of mixed nitrates and mix thoroughly, seal with a sealing film, and then carry out the sample under the same test conditions 1 H NMR test. According to the same method, three batches of different batches of TEGDN / NG mixed nitrate samples were tested, the NMR spectra were recorded, and the moisture content was calculated. The results are shown in Table 3 below.

[0053] Table 3 Determination of moisture content of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com