An integrated particle-type immobilized enzyme biosensor and its preparation method and application

A biosensor and immobilized enzyme technology, applied in the direction of biological testing, material inspection products, etc., can solve the problems of rarely using MOF response characteristics, and achieve good reusability, simplified detection steps, and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] Application of 3,5-diethyl-1,2,4-triazole copper (I), or Hdetz and cuprous ions in the preparation of immobilized enzyme biosensors.

[0040] Preferably, the immobilized enzyme biosensor has both enzyme catalytic performance and optical oxygen sensing performance.

[0041] Preferably, the enzyme is an enzyme that generates oxygen or consumes oxygen during the catalytic reaction.

[0042] More preferably, the enzyme is glucose oxidase, uric acid oxidase, D-amino acid oxidase, L-amino acid oxidase, L-α-hydroxy acid oxidase, peroxidase and the forms of these enzymes with fluorescent labels .

[0043] Preferably, the peroxidase includes catalase and horseradish peroxidase.

[0044] Preferably, the immobilized enzyme biosensor is of particle type.

[0045] An immobilized enzyme biosensor, which contains 3,5-diethyl-1,2,4-triazole copper (I) and enzyme, wherein the enzyme is immobilized on 3,5-diethyl-1,2 , within the framework of 4-triazole copper (I); or it is made of e...

Embodiment 1

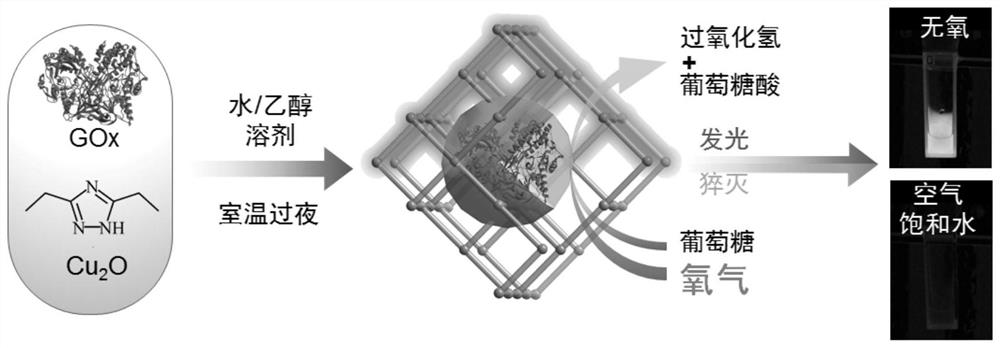

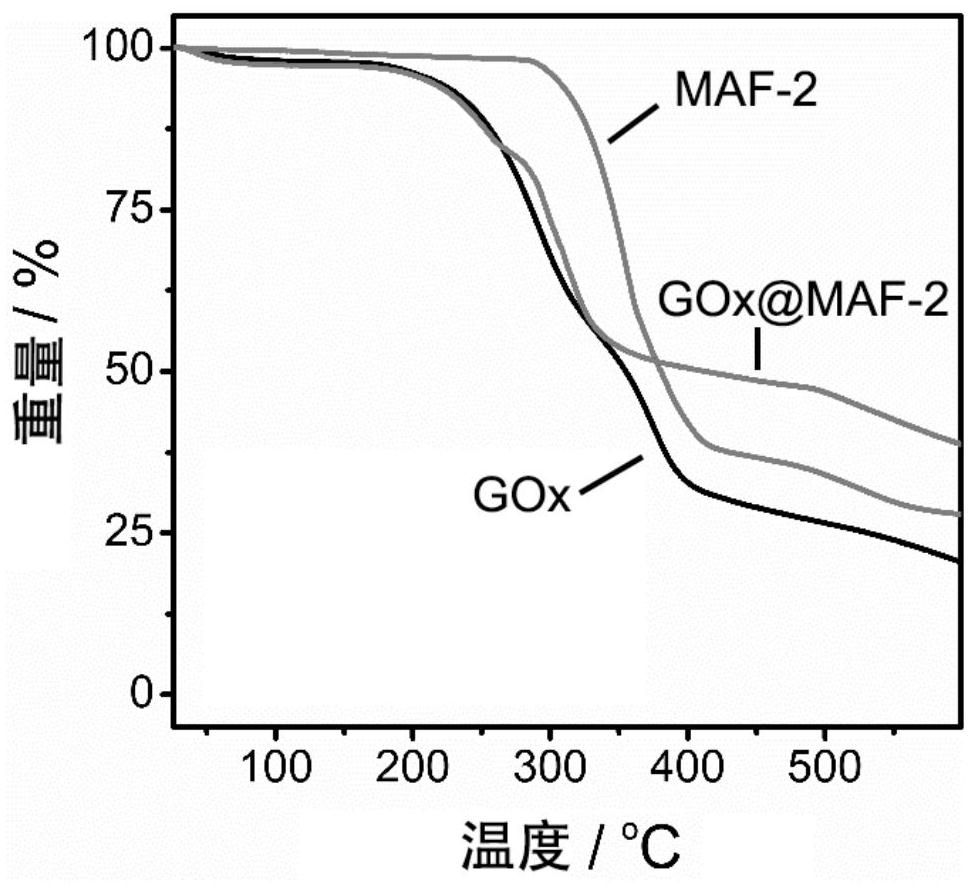

[0061] Example 1 Preparation method of an integrated particle-type immobilized enzyme biosensor

[0062] containing 0.25mmol Cu(NO 3 ) 2 Add 1gNaOH to 20mL solution of 0.25mmol ascorbic acid, quickly generate Cu 2 O nanoparticles, washed after centrifugation. Dissolve the resulting nanoparticles in 20 mL of ethanol and add a drop of hydrazine hydrate or ascorbic acid. Under nitrogen protection, the mixture was added to the ) in 15 mL of aqueous solution. After stirring overnight (12 h) at 800 rpm at room temperature, the product was collected by centrifugation at 9000 rpm for 3 minutes, washed three times with deionized water, and then lyophilized into powder to obtain the immobilized enzyme biosensor GOx@MAF-2.

Embodiment 2

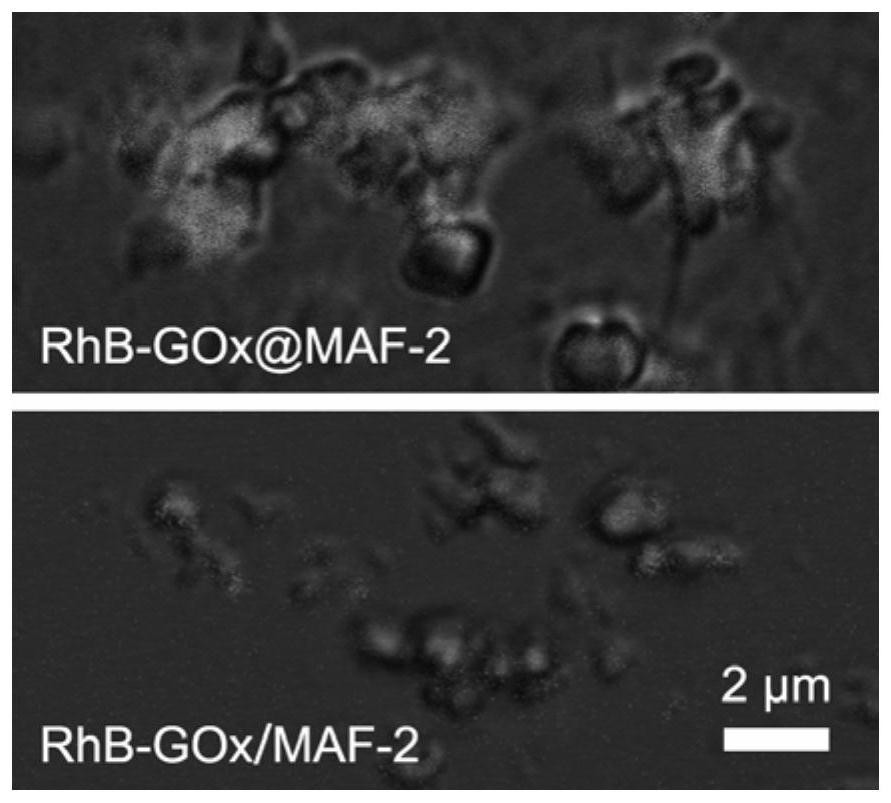

[0063] Example 2 A preparation method of an integrated particle-type immobilized enzyme biosensor

[0064] The method is the same as in Example 1, the only difference being that GOx in Example 1 is replaced by rhodamine B isothiocyanate (RhB)-labeled GOx (denoted as RhB-GOx). The immobilized enzyme biosensor finally prepared in Example 2 was designated as RhB-GOx@MAF-2.

[0065] The specific preparation method of the above-mentioned RhB-GOx is as follows: 9 mg rhodamine B isothiocyanate (RhB) was dissolved in 4 mL DMSO, and added dropwise to 2 mL GOx solution (10 mg mL -1 , 0.5M pH 9.5 carbonate buffer). The solution was stirred at room temperature at 300 rpm in the dark for 6 hours. Excess RhB was removed by acetone precipitation at -80°C for 1 hour and then centrifuged, and the enzyme labeled with fluorescent molecules was dried to obtain RhB-GOx.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com