Fluff Separators for Deposition-Type Slurry Batteries

A slurry battery and deposition-type technology, which is applied in the field of fluff diaphragm, can solve the problems of unsuitable fluidized slurry, insufficient mechanical strength of fluff, and reduce capacity attenuation, so as to improve service life, safety, and mechanical strength , the possible effect of slowing down the occurrence of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

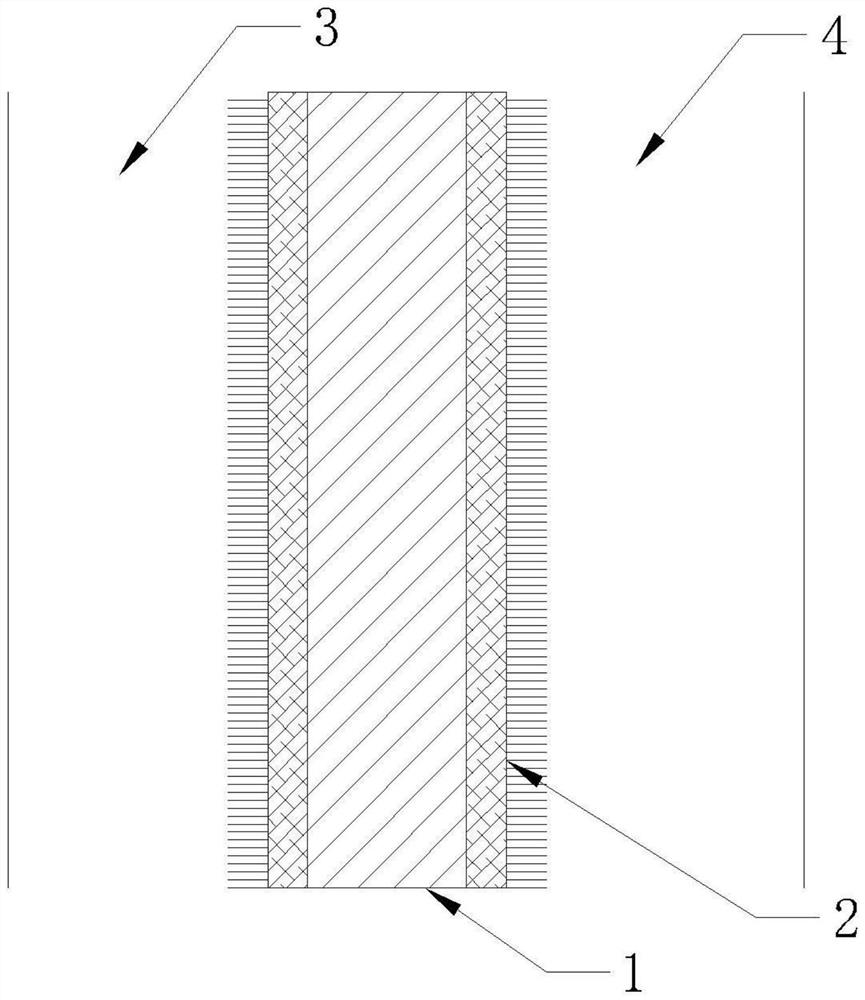

[0021] Such as figure 1 As shown, the present embodiment provides a fluff separator suitable for deposition-type slurry batteries, which includes an isolation layer 1, and a fluff layer 2 arranged on both sides of the isolation layer 1, one layer of the fluff layer 2, One layer of the isolation layer 1 and one layer of the fluff layer 2 are sequentially laminated and bonded together; wherein, the fluff of the fluff layer 2 always faces outward, and the gap between two adjacent layers is not greater than 10 μm. In this embodiment, two adjacent layers are combined into one by vacuum evaporation, electroplating, electroless plating, casting, spin coating, spray coating, hot pressing, screen printing, inkjet printing, bonding or mechanical pressing.

[0022] In this embodiment, compared with the lithium-ion battery separator in the prior art, the velvet separator can effectively reduce the frictional resistance of the slurry during the movement of the chamber, and can greatly redu...

Embodiment 2

[0032] On the basis of Example 1, this example further provides a specific preparation method for the villous diaphragm suitable for deposition-type slurry batteries:

[0033] The fluff layer 2 is set to be woven into a fabric with fluff on one side by using polytetrafluoroethylene fibers (fluorocarbon), wherein the weaving process is divided into three parts: weaving, jacquard, and cut pile. Specifically, the ground warp density is 43.8 root / cm, velvet warp density 32.7 strands / cm, weft density 36 strands / cm, fluff diameter is about 10 μm, fluff length is about 0.8mm, and the thickness of described fluff layer 2 is about 1mm; Described isolation layer 1 is set as The isolation layer 1 supported by a single-layer PE diaphragm is stretched by a dry method, the thickness of the isolation layer 1 is 26 μm, and the porosity of the isolation layer 1 is 50%.

[0034] During production, the combination process adopts a hot-pressing fusion process, one layer of the fluff layer 2, one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com