Method for preparing graphene-Nb-doped TiO<2> nanotube heterostructure photocatalyst

A photocatalyst and heterostructure technology, applied in the field of photocatalysis, can solve the problems of the photocatalytic efficiency that is difficult to reach the industrial application level, the photo-induced electron-hole recombination rate is high, and the photoresponse range is narrow, and the separation efficiency can be improved and enriched. Active sites, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

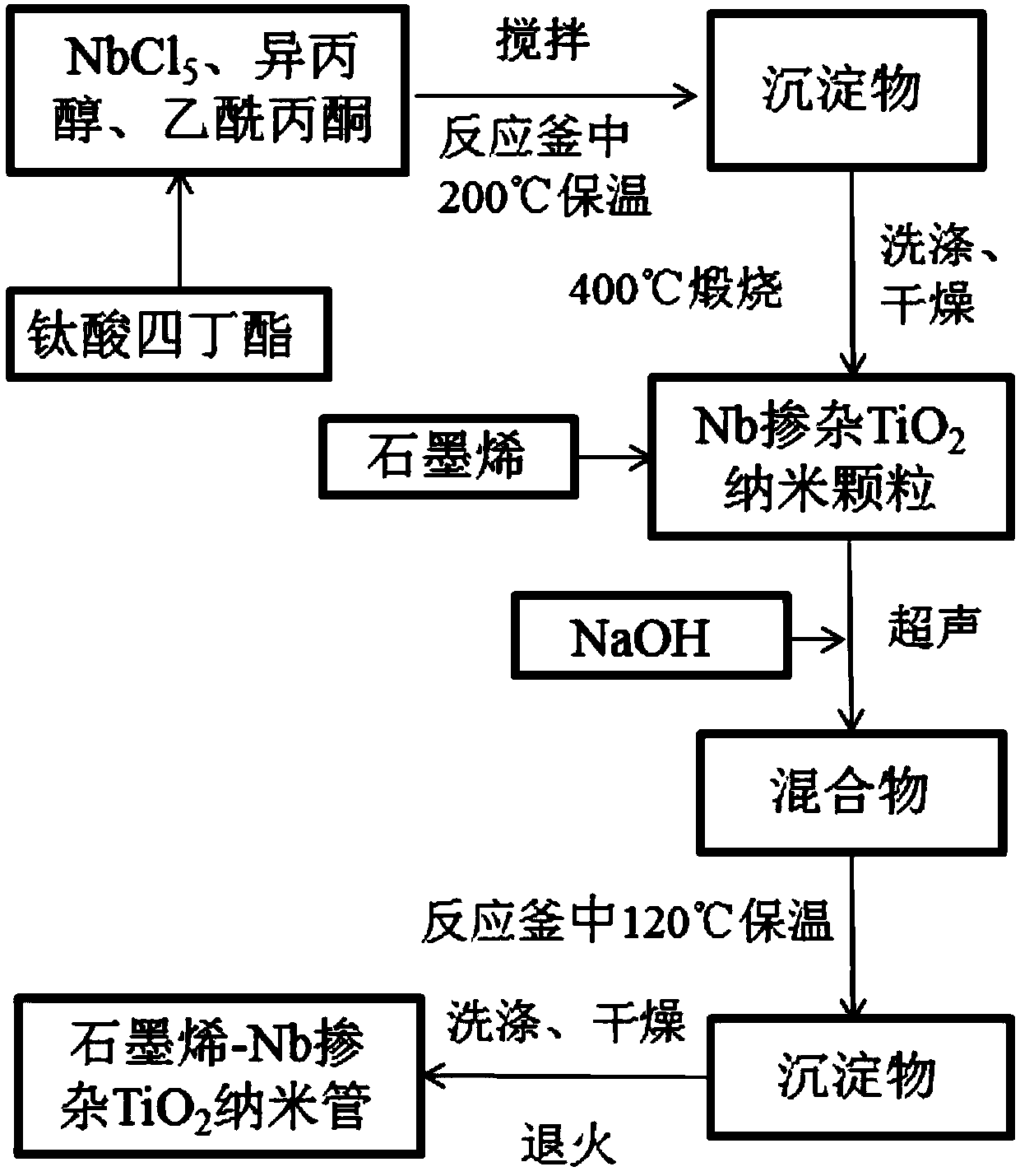

Embodiment 1

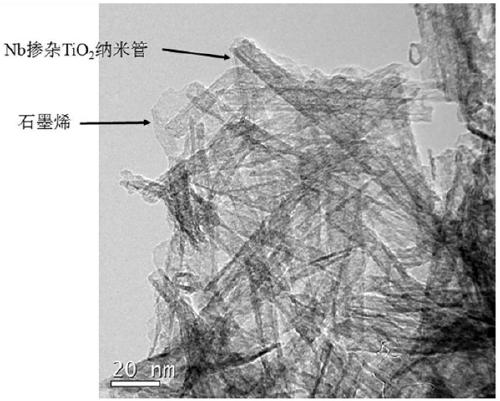

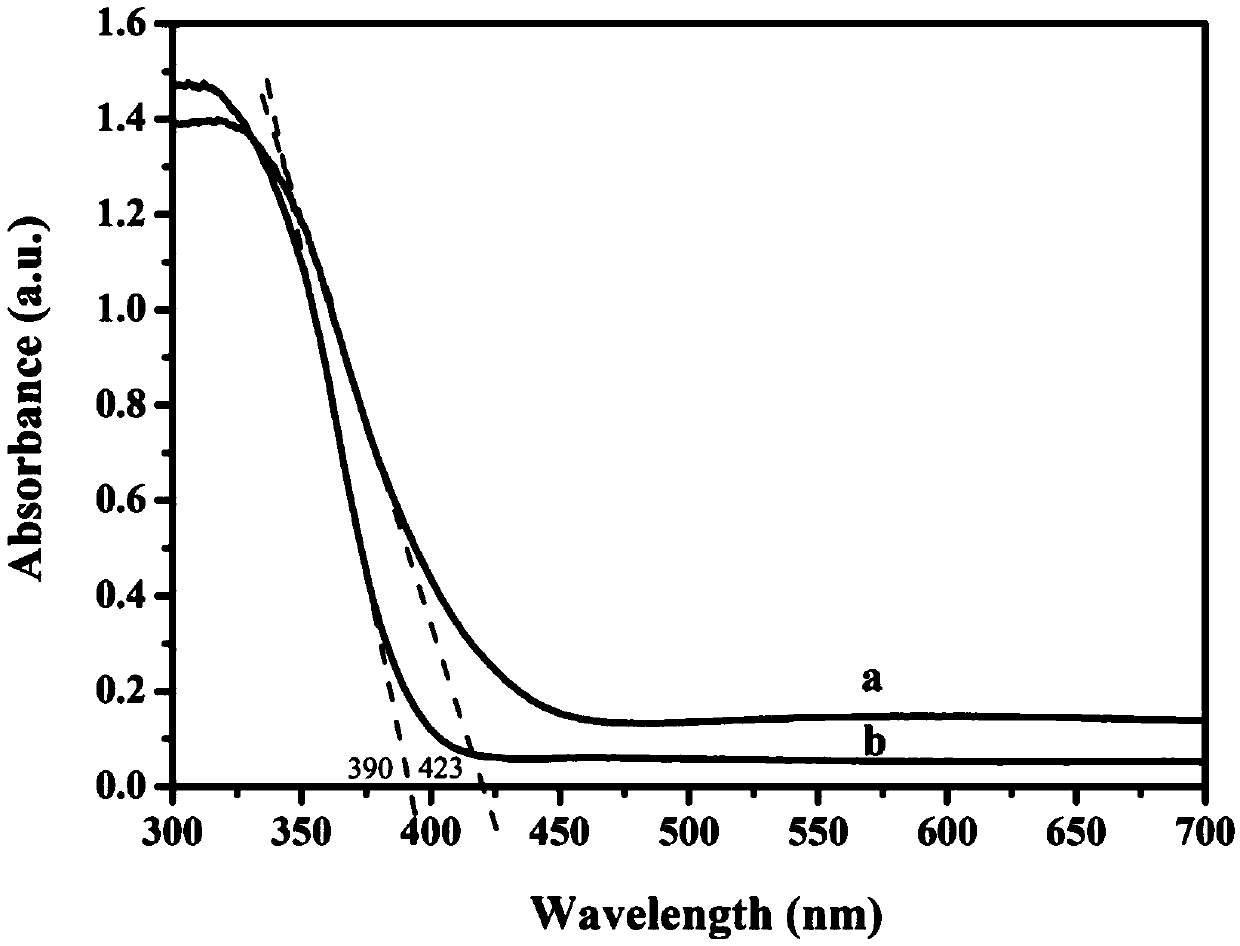

[0058] 0.18 mg of NbCl 5 Dissolve in 40ml of isopropanol and add 10ml of acetylacetone. 6 mM tetrabutyl titanate was added to the above solution, and the solution was continuously stirred at room temperature until a transparent solution was obtained, then transferred to a 100 ml reaction kettle, and kept at 200° C. for 12 hours. The obtained precipitate was washed 3 times with ethanol, dried, and then calcined at 400 °C for 1 h to obtain Nb-doped TiO 2 particles. 0.1 g graphene oxide and 1 g Nb-doped TiO 2 The powder was sonicated in deionized water for 2 h to achieve uniform dispersion, and 22 g of NaOH was added. The mixture was transferred to a reactor and kept at 120°C for 24h. The resulting precipitate was washed with 0.1M HCl to pH 2, stirred for 12 h, washed with deionized water until neutral, dried, and annealed at 400 °C for 1 h under a nitrogen atmosphere to obtain graphene-Nb doped TiO 2 Nanotube composite samples.

[0059] The photocatalytic performance of th...

Embodiment 2

[0068] First, 5.46 mg of NbCl 5 Dissolve in 40ml of isopropanol and add 10ml of acetylacetone. 6 mM tetrabutyl titanate was added to the above solution, and the solution was continuously stirred at room temperature until a transparent solution was obtained, which was transferred to a reaction kettle and kept at 200° C. for 12 hours. The obtained precipitate was washed with ethanol, dried, and calcined at 300 °C for 2 h to obtain Nb-doped TiO 2 particles. 0.1 g graphene oxide and 1 g Nb-doped TiO 2 The powder was sonicated in deionized water for 2 h to achieve uniform dispersion, and 22 g of NaOH was added. The mixture was transferred to a reactor and kept at 120°C for 24h. The resulting precipitate was washed with 1M HCl solution, stirred for 12 h, washed with deionized water, and dried to obtain graphene-Nb doped TiO 2 Nanotube composite powder. Using the same photocatalytic degradation conditions as in Example 1 to test the catalytic performance of the sample, when the...

Embodiment 3

[0070] First, 1.09 mg of NbCl 5 Dissolve in 40ml of isopropanol and add 10ml of acetylacetone. 6 mM tetrabutyl titanate was added to the above solution, and the solution was continuously stirred at room temperature until a transparent solution was obtained, which was transferred to a reaction kettle and kept at 200° C. for 12 hours. The obtained precipitate was washed with ethanol, dried, and calcined at 500 °C for 2 h to obtain Nb-doped TiO 2 particles. 0.1 g graphene oxide and 10 g Nb-doped TiO 2 The powder was sonicated in deionized water for 2 h to achieve uniform dispersion, and 22 g of NaOH was added. The mixture was transferred to a reactor and kept at 120°C for 24h. The resulting precipitate was washed with 1M HCl solution, stirred for 12 h, washed with deionized water, and dried to obtain graphene-Nb doped TiO 2 Nanotube composite powder. The same photocatalytic degradation conditions as in Example 1 were used to test the catalytic performance of the sample. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com