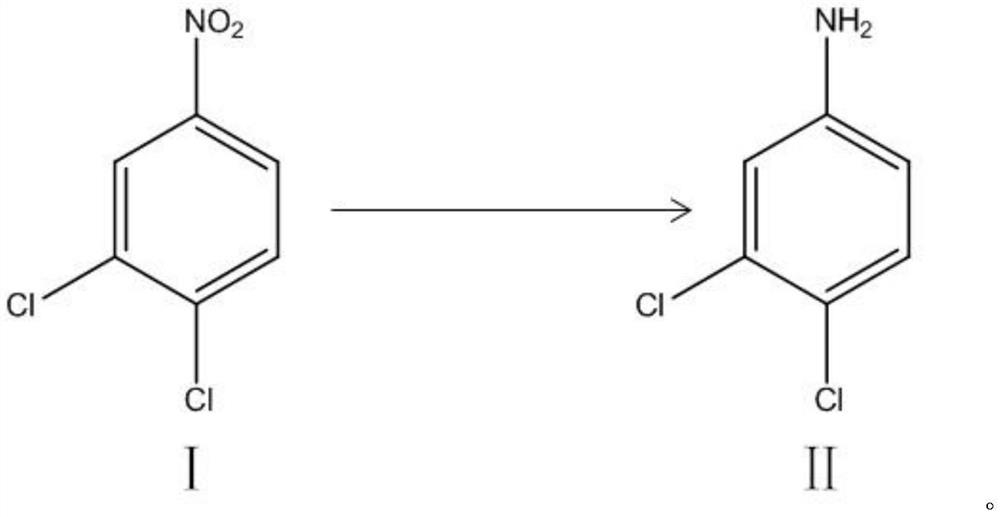

A photothermal catalytic hydrogenation catalyst and its preparation and application in the selective hydrogenation of 3,4-dichloronitrobenzene

A technology of hydrogenation catalyst and photothermal catalysis, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, amino compound preparation, etc., and can solve the problem of low yield of 3,4-dichloroaniline , complex operation steps and other issues, to achieve good stability, simple and controllable groups, and eliminate the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

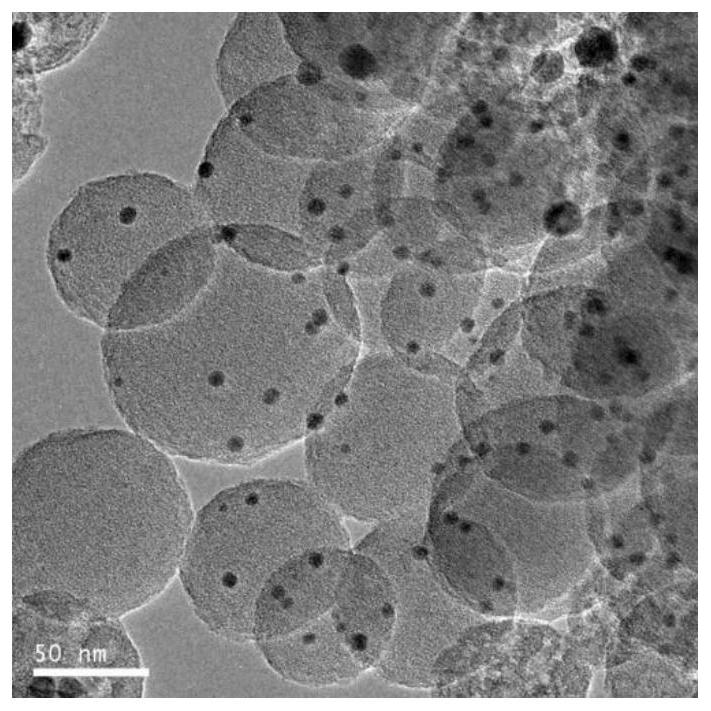

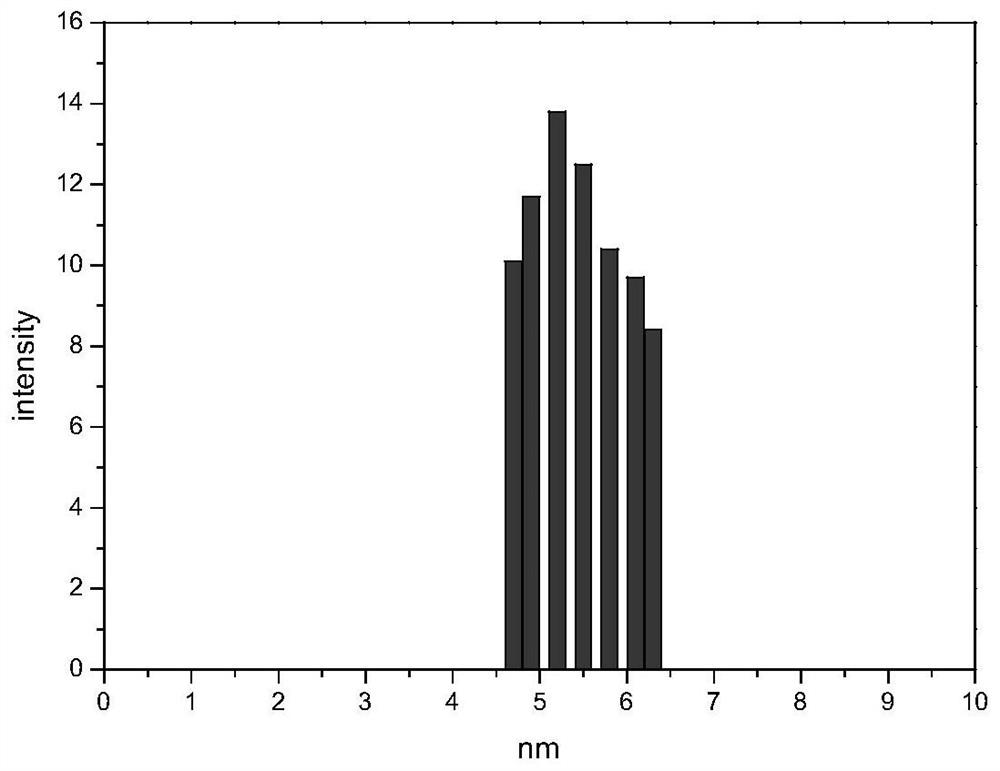

Image

Examples

Embodiment 1

[0039] Measure 1ml of ammonia water with a mass concentration of 23%, 32ml of ethanol and 80ml of deionized water and mix them thoroughly, then add 3.5g of 3-aminophenol, stir until completely dissolved, then drop in 5ml of formaldehyde solution with a mass concentration of 35%, and leave at room temperature After stirring at low temperature for 4 hours, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 200°C for 24 hours. After cooling to room temperature, it was placed in an oven and dried at 60°C for 24 hours to obtain polymer microspheres.

[0040] Weigh 1g of polymer microspheres and 15ml of deionized water and stir evenly, then put the prepared mixed slurry into a microwave digestion apparatus, set the temperature at 195°C, and microwave reaction time of 25 minutes, carry out microwave reaction, take out the mixed slurry after cooling down Put the slurry into a vacuum oven, and dry at 60° C. for 24 hours at a relative vacuum degree of -0.09...

Embodiment 2

[0045] Measure 1ml of ammonia water with a mass concentration of 20%, 20ml of ethanol and 70ml of deionized water and mix them thoroughly, then add 2g of 3-aminophenol, stir until completely dissolved, and then drop in 2ml of formaldehyde solution with a mass concentration of 33%. After stirring for 2 hours, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 100°C for 12 hours. After cooling to room temperature, it was put into an oven and dried at 20°C for 12 hours.

[0046] Weigh 1g of polymer microspheres and 15ml of deionized water and stir evenly, then put the prepared mixed slurry into a microwave digestion apparatus, set the temperature at 195°C, and microwave reaction time of 25 minutes, carry out microwave reaction, take out the mixed slurry after cooling down Put the slurry into a vacuum oven, and dry at 60° C. for 24 hours at a relative vacuum degree of -0.099 to -0.05 MPa to obtain a solid powder.

[0047] After mixing 1g of the carbo...

Embodiment 3

[0051] Measure 1ml of ammonia water with a mass concentration of 25%, 60ml of ethanol and 100ml of deionized water and mix them thoroughly, then add 5g of 3-aminophenol, stir until completely dissolved, and then drop in 8ml of formaldehyde solution with a mass concentration of 38%. After stirring for 10 hours, it was transferred to a hydrothermal reaction kettle for hydrothermal reaction at 300° C. for 48 hours. After cooling to room temperature, it was put into an oven and dried at 80° C. for 48 hours.

[0052] Weigh 1g of polymer microspheres and 15ml of deionized water and stir evenly, then put the prepared mixed slurry into a microwave digestion apparatus, set the temperature at 195°C, and microwave reaction time of 25 minutes, carry out microwave reaction, take out the mixed slurry after cooling down Put the slurry into a vacuum oven, and dry at 60° C. for 24 hours at a relative vacuum degree of -0.099 to -0.05 MPa to obtain a solid powder.

[0053] After mixing 1g of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com