Fatty alcohol ether carboxylic acid preparation method

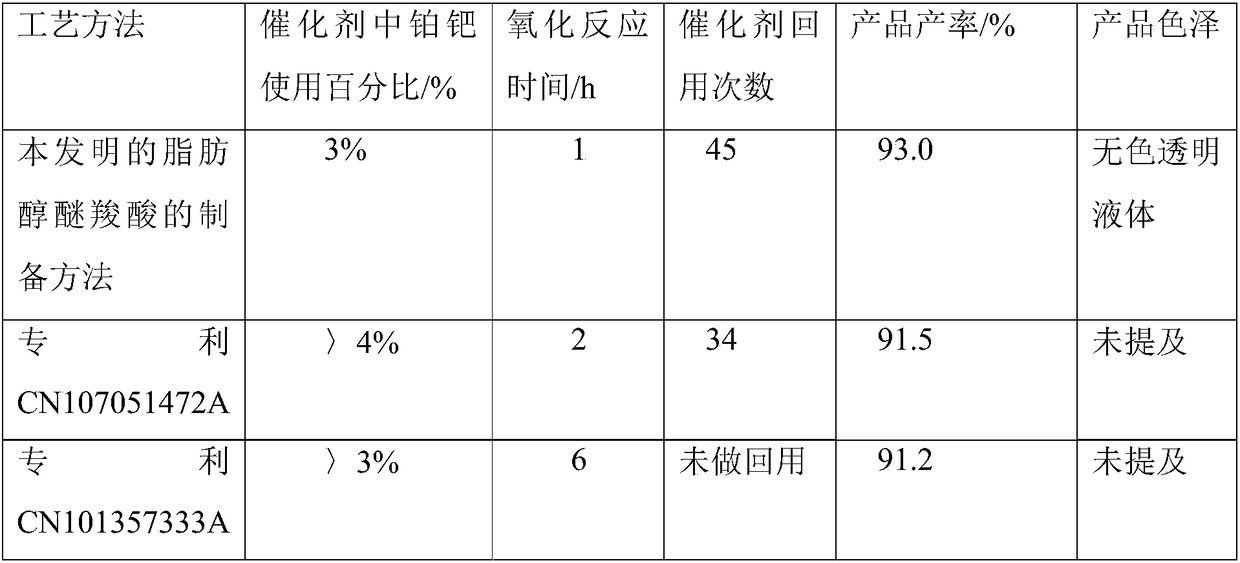

An alcohol ether carboxylic acid and aliphatic alcohol ether technology, which is applied in the field of surfactant preparation, can solve the problems of difficult recovery of precious metal catalysts, weakened catalyst activity, reduced catalyst activity, etc., and achieves easy control of production process, low energy consumption, and reaction rate. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

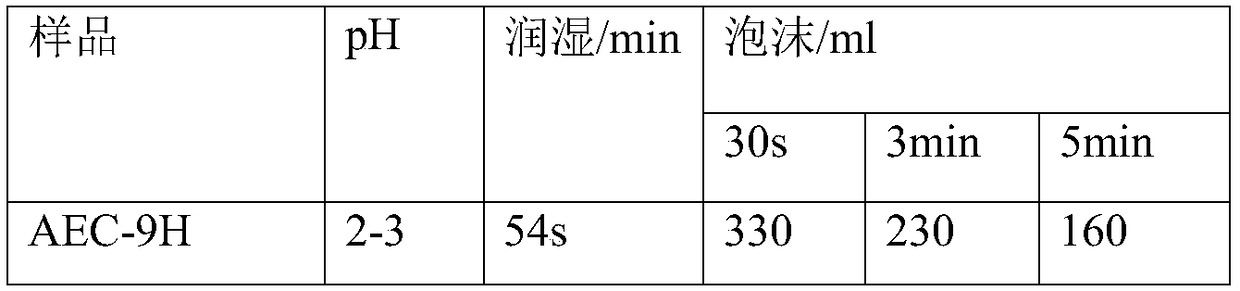

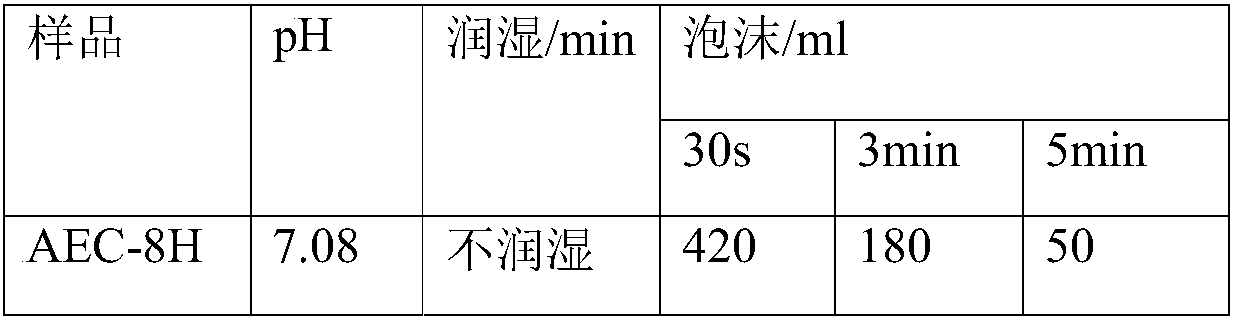

Examples

Embodiment 1

[0041] In a 1L high-pressure reactor, according to the molar ratio of alcohol ether and sodium hydroxide being 1:1, and the concentration of alcohol ether dissolved in deionized water is 20% (80 / (320+80)=20%), add 0.13 mol 80g of AEO9 alcohol ether and 320g of deionized water, add 0.13mol 5.2g of sodium hydroxide, start stirring, the stirring speed is 100rpm, heat up to 80°C to make it dissolve evenly, at 80°C, add 14g of palladium The carbon composite catalyst is fed with oxygen and replaced twice. The oxygen is industrial oxygen with a content of >99%. Under the condition of a stirring speed of 200rpm, the oxygen pressure of the system is kept at an absolute pressure of 0.11MPa, and it is kept constant by intermittent or continuous oxygen feeding. Oxygen pressure, turn on the oxygen circulation pump, react until the oxygen pressure does not change, use the circulation pump to realize the circulation of oxygen in the reactor from above the liquid level into the liquid, the oxi...

Embodiment 2

[0045] In a 1L high-pressure reactor, according to the molar ratio of alcohol ether and sodium hydroxide feeding 1:1.08, the concentration of alcohol ether dissolved in deionized water is 20%, add 0.13mol 80g of AEO9 alcohol ether and 320g of deionized water , add 0.14mol 5.6g of sodium hydroxide, start stirring, the stirring speed is 300rpm, raise the temperature to 70°C to make it dissolve evenly, under the condition of 70°C, add 10g of palladium-carbon composite catalyst, pass in oxygen and replace twice, Oxygen is industrial oxygen with a content >99%. Under the condition of stirring speed of 100rpm, the oxygen pressure of the system is kept at an absolute pressure of 0.13MPa, and the oxygen pressure is kept constant by intermittent or continuous oxygen feeding. The pressure does not change anymore, and the circulation pump is used to realize the circulation of oxygen in the reactor from above the liquid level into the liquid. The oxidation reaction time is 1h and the react...

Embodiment 3

[0049] In a 1L high-pressure reactor, according to the molar ratio of alcohol ether and sodium hydroxide as 1:1.125, the concentration of alcohol ether dissolved in deionized water is 25%, add 0.16mol 100g of narrow distribution AEO9 alcohol ether and 300g of deionized water Ionized water, add 0.18mol7.2g of sodium hydroxide, start stirring, the stirring speed is 200rpm, heat up to 80°C to make it dissolve evenly, under the condition of 80°C, add 15g of platinum-carbon composite catalyst, pass in oxygen and replace the two Second, oxygen is industrial oxygen with a content >99%. Under the condition of a stirring speed of 300rpm, the oxygen pressure of the system is kept at an absolute pressure of 0.15MPa, and the oxygen pressure is kept constant by intermittent or continuous oxygen feeding. The oxygen circulation pump is turned on, and the reaction Until the oxygen pressure no longer changes, the circulation pump is used to realize the circulation of oxygen in the reactor from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com