Electroplating method and electroplating solution for anti-corrosion and wear-resistant workpiece

A technology for electroplating solutions and metal workpieces, applied in chemical instruments and methods, electrolytic coatings, ceramic products, etc., can solve the problems of low fusion, low hardness, poor corrosion resistance, etc., and achieve the effect of improving wear resistance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

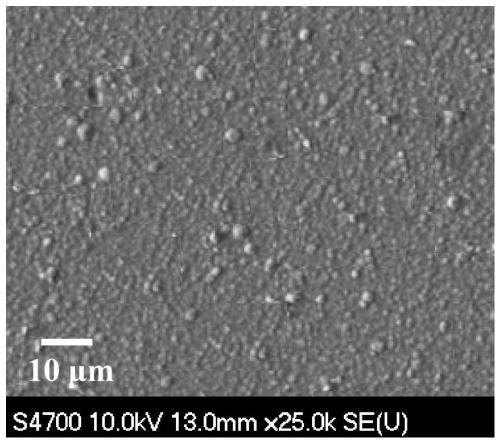

[0038] S1: Pretreatment: the surface of the metal workpiece is pretreated by grinding, chemical degreasing, electrochemical activation and deionized water washing in sequence;

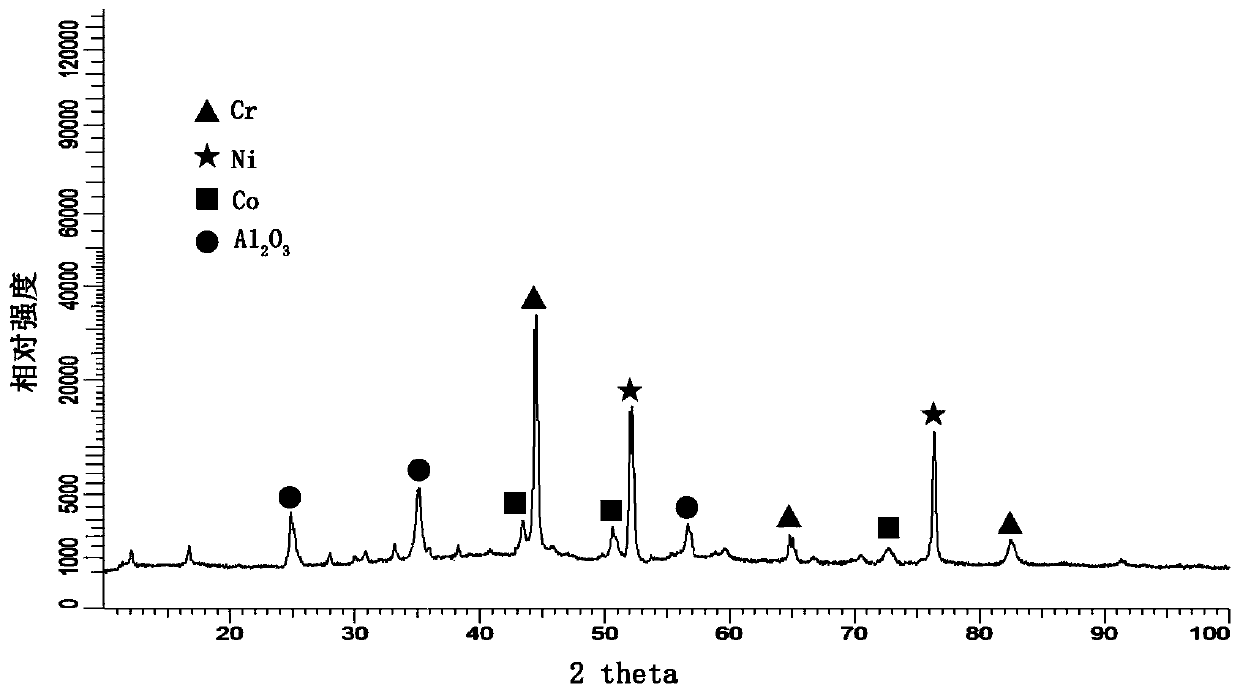

[0039] S2: Preparation of electroplating solution: Prepare electroplating solution according to the following concentrations: chromium sulfate 75g / L, nickel sulfate 50g / L, cobalt sulfate 25g / L, hollow porous alumina microspheres 15g / L, boric acid 55g / L, ammonium chloride 60g / L, citric acid 120g / L, sodium octadecyl sulfonate 3g / L;

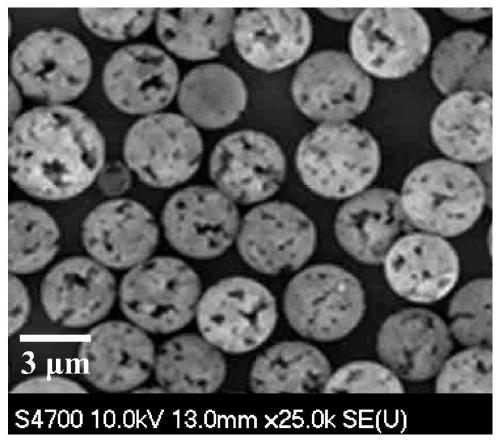

[0040] The preparation method of the hollow porous alumina microspheres comprises the following steps:

[0041] Step 1, add 15 parts of monomer mixture, 0.4 part of polyvinylpyrrolidone, 0.3 part of initiator azobisisobutyronitrile to 120 parts of absolute ethanol according to parts by weight, mix uniformly with the aid of ultrasonic, and then add nitrogen The polymerization reaction is carried out in the atmosphere, the polymerization temperature is 80 ° C, and the reactio...

Embodiment 2

[0046] S1: Pretreatment: the surface of the metal workpiece is pretreated by grinding, chemical degreasing, electrochemical activation and deionized water washing in sequence;

[0047] S2: Preparation of electroplating solution: Prepare electroplating solution according to the following concentrations: chromium sulfate 50g / L, nickel sulfate 40g / L, cobalt sulfate 20g / L, hollow porous alumina microspheres 12g / L, boric acid 35g / L, ammonium chloride 55g / L, citric acid 100g / L, sodium octadecyl sulfonate 1g / L;

[0048] The preparation method of the hollow porous alumina microspheres comprises the following steps:

[0049] Step 1, according to weight parts, add 10 parts of monomer mixture, 0.2 part of polyvinylpyrrolidone, 0.1 part of initiator azobisisobutyronitrile to 100 parts of anhydrous ethanol, mix well with the aid of ultrasonic, and then under nitrogen The polymerization reaction is carried out in the atmosphere, the polymerization reaction temperature is 75 ° C, and the re...

Embodiment 3

[0054] S1: Pretreatment: the surface of the metal workpiece is pretreated by grinding, chemical degreasing, electrochemical activation and deionized water washing in sequence;

[0055] S2: Preparation of electroplating solution: Prepare electroplating solution according to the following concentrations: chromium sulfate 60g / L, nickel sulfate 45g / L, cobalt sulfate 22g / L, hollow porous alumina microspheres 14g / L, boric acid 40g / L, ammonium chloride 58g / L, citric acid 110g / L, sodium octadecyl sulfonate 2g / L;

[0056] The preparation method of the hollow porous alumina microspheres comprises the following steps:

[0057] Step 1, according to weight parts, add 12 parts of monomer mixture, 0.3 part of polyvinylpyrrolidone, 0.3 part of initiator azobisisobutyronitrile to 110 parts of absolute ethanol, mix uniformly with the aid of ultrasound, and then add nitrogen The polymerization reaction is carried out in the atmosphere, the polymerization temperature is 77 ° C, and the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com