Biomass-based super-hydrophobic paper and preparation method thereof

A super-hydrophobic paper and biomass technology, applied in pulp beating method, non-woody plant/crop pulp, papermaking, etc., can solve the problem of high cost, and achieve mild reaction conditions, good super-hydrophobic properties, and good friction resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of biomass-based super-hydrophobic paper, which comprises the following processing steps:

[0030] 1) Take the coniferous wood fiber pulp board, rinse it with ethanol and deionized water in sequence, and then put it in an oven at 60°C to dry for 6 hours;

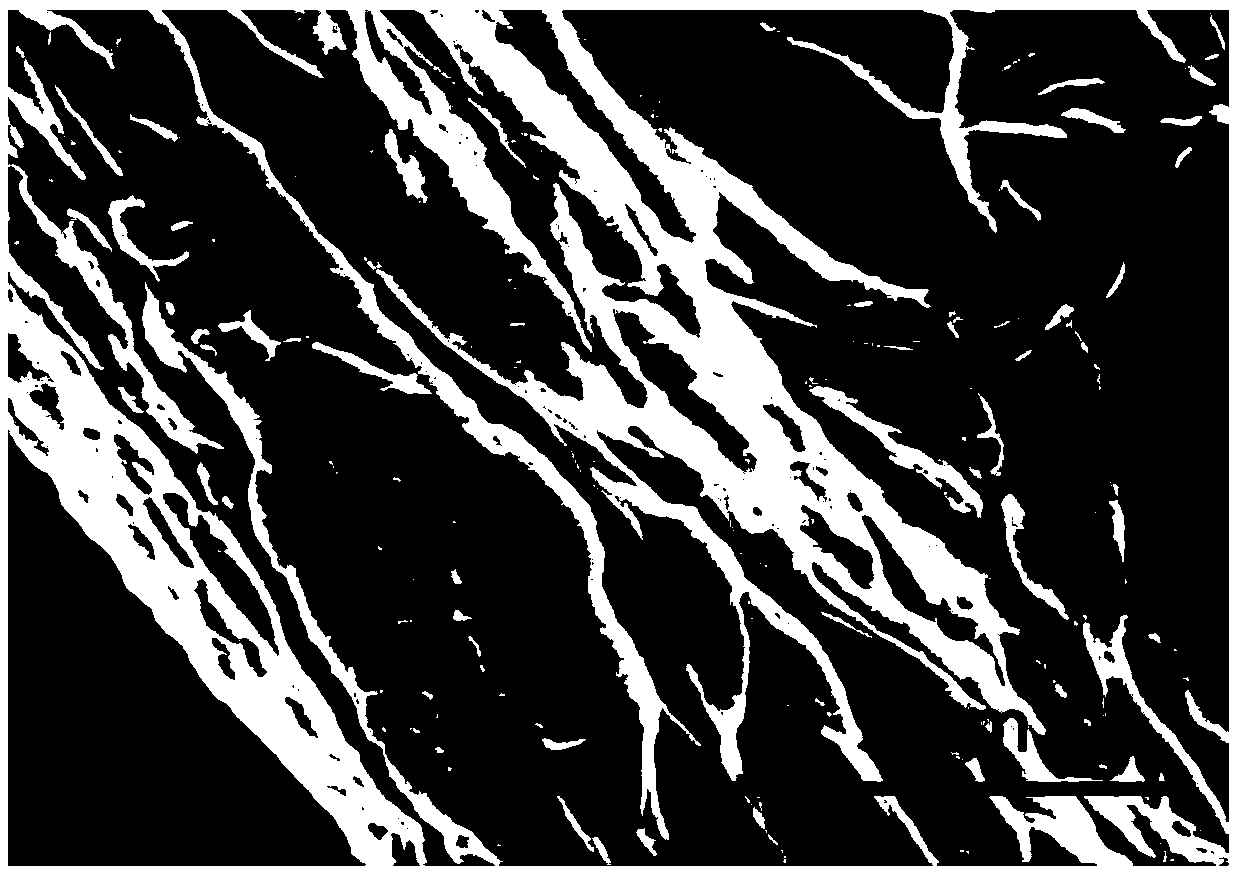

[0031] 2) Soak the coniferous wood fiber pulp board with deionized water, and then perform mechanical beating to obtain an absolute dry coniferous wood fiber pulp with a beating degree of 60 ° SR (its scanning electron microscope picture is as attached figure 1 shown);

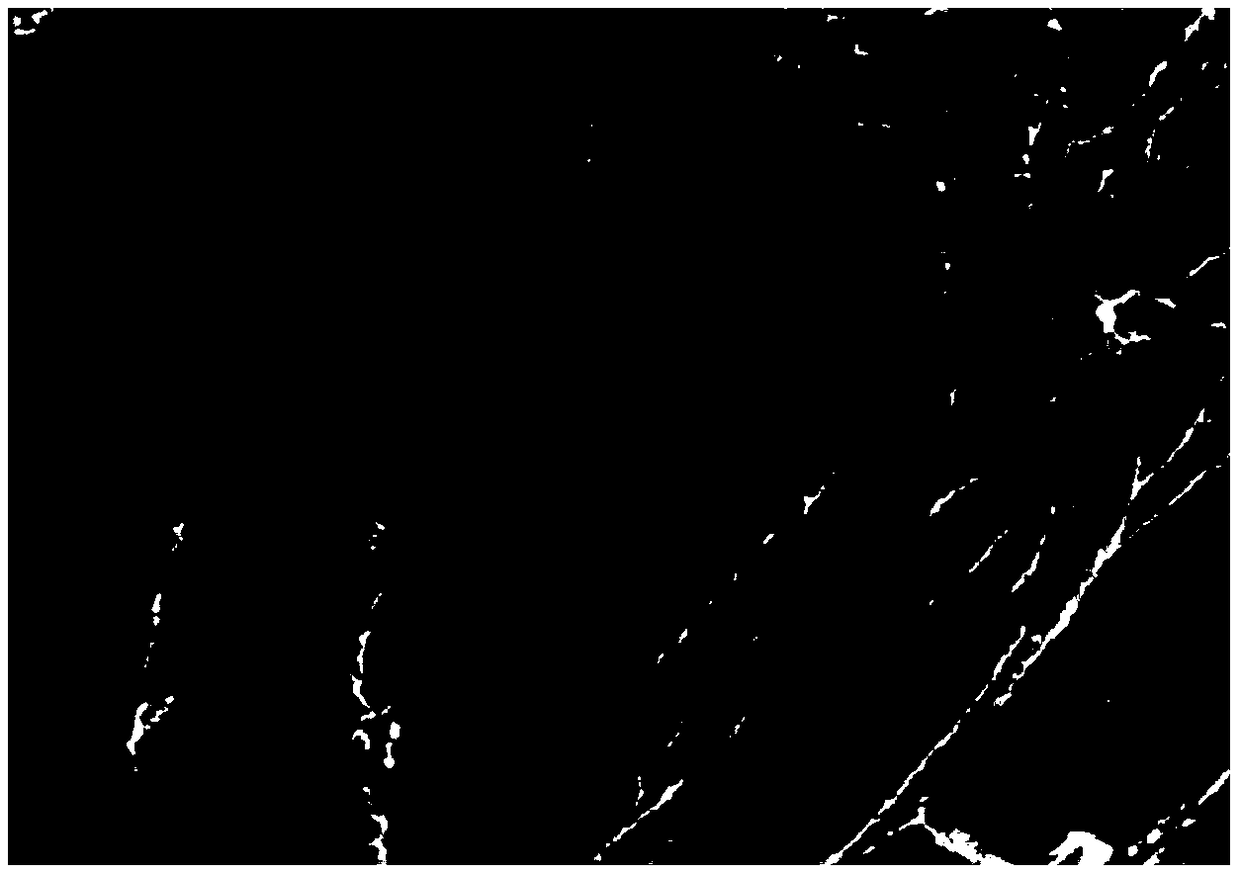

[0032] 3) Mechanically stir 1 g of dry coniferous wood fiber slurry with ethanol solution for 15 min, then add tetraethyl titanate and 0.2 g of acetic acid (concentration: 36%), and react at 25°C for 3 h. Centrifugal, clean with ethanol, obtain modified coniferous wood fiber (its scanning electron micrograph is as attached figure 2 shown), stored at 0-4°C;

[0033] 4) According to the demand of quantitative 40g, paper is made ...

Embodiment 2

[0036] A preparation method of biomass-based super-hydrophobic paper, which comprises the following processing steps:

[0037] 1) Take the hardwood fiber pulp board, rinse it with ethanol and deionized water in sequence, and then put it in an oven at 50°C to dry for 6 hours;

[0038] 2) Soak and decompose the hardwood fiber pulp board with deionized water, then perform mechanical beating to obtain an absolute dry hardwood fiber slurry with a beating degree of 50 ° SR;

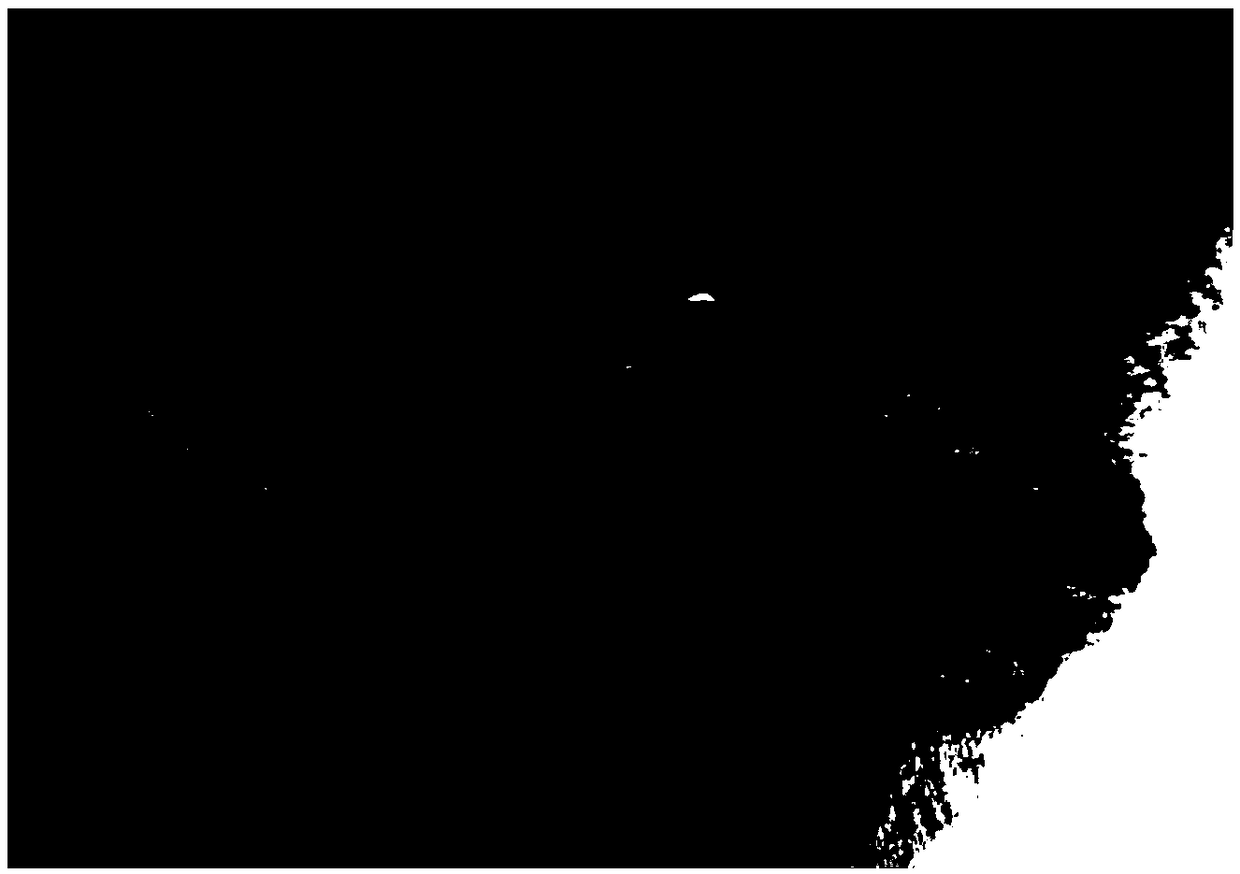

[0039] 3) Mechanically stir 1 g of dry hardwood fiber slurry with ethanol solution for 30 min, then add butyl titanate and 0.2 g of acetic acid (concentration: 36%), and react at 25°C for 4 h, centrifuge after the reaction , washed with ethanol to obtain modified broad-leaved wood fiber (the scanning electron micrograph is as attached Figure 4 shown), stored at 0-4°C;

[0040] 4) According to the demand of quantitative 60g, use modified broad-leaved wood fiber to make paper, adopt hexadecyltrimethoxysilane (...

Embodiment 3

[0042] A preparation method of biomass-based super-hydrophobic paper, which comprises the following processing steps:

[0043] 1) Take the bamboo fiber pulp board, wash it successively with ethanol and deionized water, and then put it into an oven at 70°C to dry for 6 hours;

[0044] 2) soaking and dissolving the bamboo fiber pulp board with deionized water, then performing mechanical beating to obtain the absolute dry bamboo fiber pulp with a beating degree of 60 ° SR;

[0045] 3) Mechanically stir 1 g of dry bamboo fiber slurry with ethanol solution for 20 min, then add tetraethyl titanate and 0.2 g of acetic acid (concentration: 36%), and react at 50°C for 5 h, centrifuge after the reaction , washed with ethanol to obtain modified bamboo fiber (the scanning electron micrograph is as attached Figure 5 shown), stored at 0-4°C;

[0046] 4) According to the demand of quantitative 60g, use modified bamboo fiber to make paper, adopt octadecyltrimethoxysilane (addition amount i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com