A solid electrolyte membrane and its preparation method and application

A solid electrolyte membrane and electrolyte membrane technology, applied in the field of lithium-ion batteries, can solve problems such as poor compatibility and no large-scale production, and achieve the effects of low cost, reduced impedance, and improved safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides a method for preparing the above solid electrolyte membrane, which specifically includes the following steps:

[0043] S1. Dissolve the matrix and the lithium salt in an organic solvent, ultrasonically disperse, and fully stir to obtain a mixed solution. In the total mass of the matrix and the lithium salt, the content of the lithium salt is 10 wt% to 70 wt%. The concentration of the matrix in the mixed solution is 10-30 wt%. There are no special requirements for the selection of organic solvents, and can be selected according to actual needs. For example, in the embodiment of the present invention, the solvent may be at least one of N,N-dimethylformamide (DMF), N-methylpyrrolidone (NMP), acetonitrile and acetone.

[0044] The solution including the matrix and the lithium salt is ultrasonically dispersed for sufficient dissolution. There is no special requirement for the ultrasonic dispersion time and can be adjusted according to actual need...

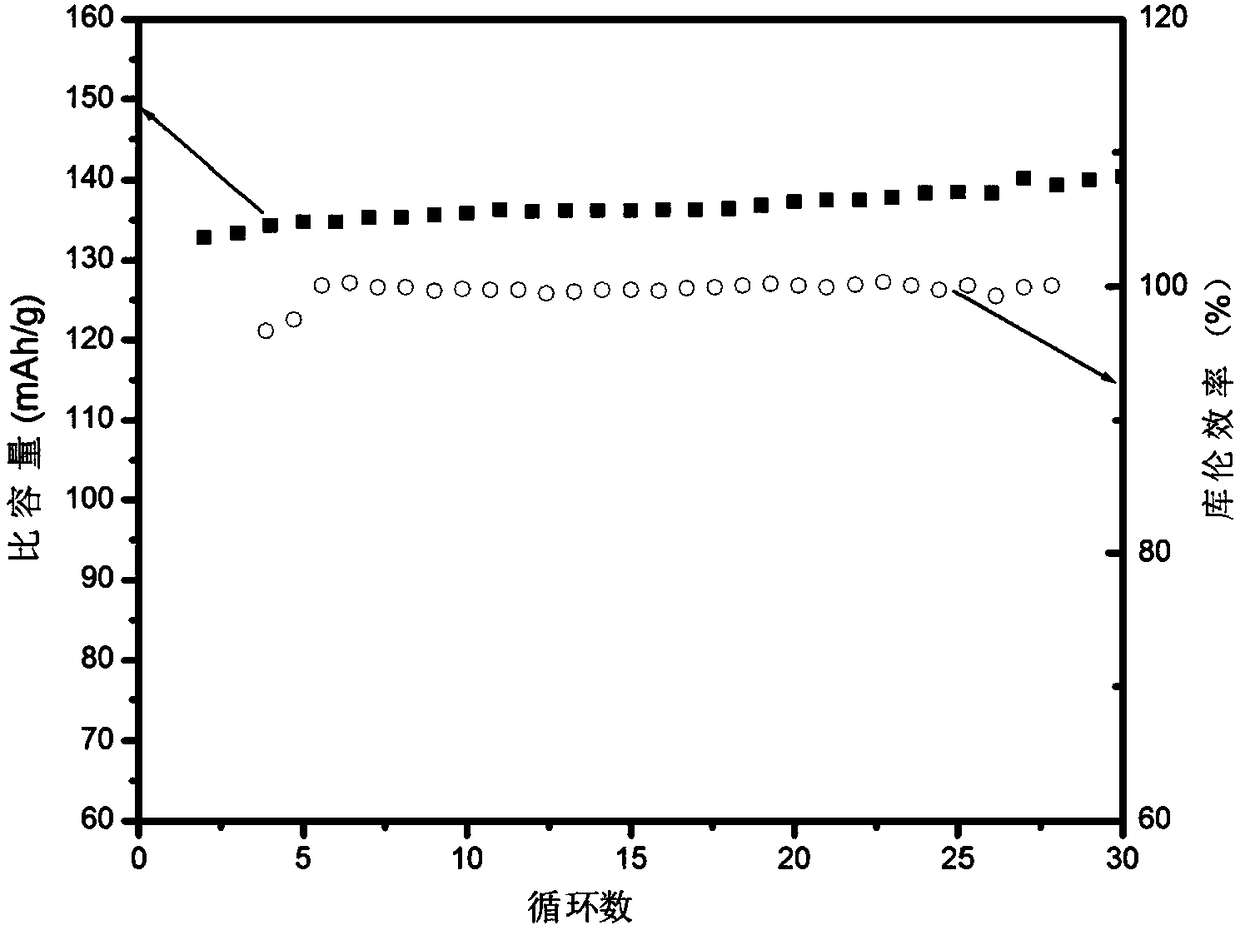

Embodiment 1

[0054] A solid electrolyte membrane composed of polyvinylidene fluoride (PVDF), lithium bis(trifluoromethylsulfonate) imide (LITFSI), LLZTO (Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 ), bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI), and ethylene carbonate (EC).

[0055] The preparation method is as follows: first dissolve PVDF and LITFSI in DMF solvent, stir magnetically at 60° C. for 8 hours to obtain a mixed solution. Among them, LITFSI accounts for 30wt% of the total mass of PVDF and LITFSI, and the mass concentration of the PVDF solution is 10%. Then, add nanometer Li to the mixed solution of PVDF and LITFSI in sequence 6.4 La 3 Zr 1.4 Ta 0.6 O 12 , EMITFSI and EC, added Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 Account for Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 And 10wt% of the total mass of PVDF, the added masses of EMITFSI and EC are respectively 20wt% of the total mass of the EMITFSI and PVDF mixture, and 5wt% of the total mass of the EC and PVDF mixture, continue magnetic stirring f...

Embodiment 2

[0057] A solid electrolyte membrane consisting of polyethylene oxide (PEO), lithium bis(trifluoromethylsulfonate) imide (LITFSI), LLZTO (Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 ), bis(trifluoromethylsulfonyl) 1-ethyl-3-methylimidazole (EMITFSI), and ethylene carbonate (EC).

[0058] The preparation method is as follows: first dissolve PEO and LITFSI in DMF solvent, and magnetically stir at 60°C for 8 hours to obtain a mixed solution. Among them, LITFSI accounts for 30wt% of the total mass of PEO and LITFSI, and the mass concentration of the PVDF solution is 10%. After that, add nanometer Li to the PEO and LITFSI mixed solution. 6.4 La 3 Zr 1.4 Ta 0.6 O 12 , EMITFSI and EC, added Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 Account for Li 6.4 La 3 Zr 1.4 Ta 0.6 O 12 And 20wt% of the total mass of PEO, the added masses of EMITFSI and EC are respectively 20wt% of the total mass of the EMITFSI and PEO mixture, and 5wt% of the total mass of the EC and PEO mixture. Continue magnetic stirring for 4h and fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com