Comfortable flame-retardant cloth and processing technique thereof

A processing technology and comfort technology, applied in the field of flame retardant fabric and its processing technology, can solve the problem that the flame retardant fabric cannot meet the flame retardant function and comfortable wearability at the same time, and achieve the optimized soft hand, comfortable hand and soft hand feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

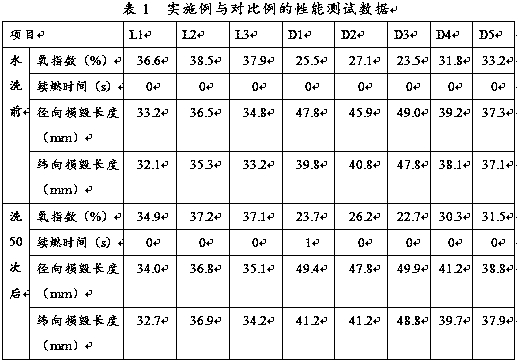

Examples

preparation example 1

[0064] Preparation Example 1 Flame Retardant Cotton Fiber

[0065] Use potassium hydroxide with a mass fraction of 9% and urea with a mass fraction of 9% as a mixed solution, soak ordinary cotton fibers for 6 hours, take them out, wash with water until neutral, and dry;

[0066] The dried cotton fiber is dipped in zinc oxide colloid, then subjected to gel aging and supercritical drying to obtain flame-retardant cotton fiber loaded with nano-zinc oxide, and in terms of mass percentage, the loading amount of nano-zinc oxide is 14 %. Among them, the aging time of the gel is 2-10 hours, and the conditions for ultra-close drying are 50-60°C and 20 MPa.

preparation example 2

[0067] Preparation example two flame retardant polyester fiber

[0068] Preparation of liquid containing flame retardant: take nano talc powder and disperse evenly in the mixed liquid of aminoorganosilicon quaternary ammonium salt, ethanol and water. Wherein, in terms of mass percentage, talcum powder is 25%, quaternary ammonium salt is 25%, ethanol is 10%, and water is 40%.

[0069] Immerse ordinary polyester fibers in the above-mentioned flame retardant-containing liquid, take them out after soaking, and dry to obtain a composite material of nano talc powder and polyester, which is a flame-retardant polyester fiber.

preparation example 3

[0070] Preparation Example 3 Flame-retardant acrylic fiber

[0071] Using anhydrous DMF as a solvent, add acryloyl chloride dropwise to nano-silica containing hydroxyl groups on the surface under ice bath conditions, and centrifugally purify to obtain an intermediate product;

[0072] Acrylonitrile, methyl acrylate, sodium allyl sulfonate, and intermediate products are used as monomers (the mass ratio of materials in monomers is 92:3.5:0.5:4), AIBN is used as an initiator, and sodium thiocyanate is used The aqueous solution is used as a solvent, thiourea dioxide is used as a light coloring agent, isopropanol is used as a regulator, and a 55% sodium thiocyanate aqueous solution is used as a solvent to react to obtain modified polyacrylonitrile, and the modified polyacrylonitrile is wetted. Spinning method to obtain flame retardant acrylic fiber.

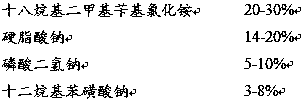

[0073] Wherein, the mass percent of each feed intake is:

[0074] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com