WO3/BiVO4/FeOOH ternary system composite material and preparation method and application thereof

A technology of composite materials and ternary systems, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as limited applications, and achieve good repeatability and process Simple and controllable, the effect of photocatalytic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

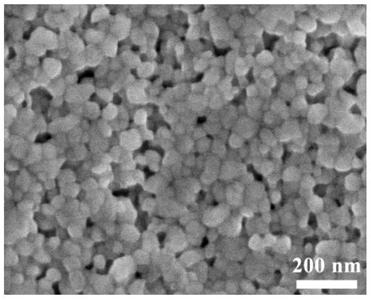

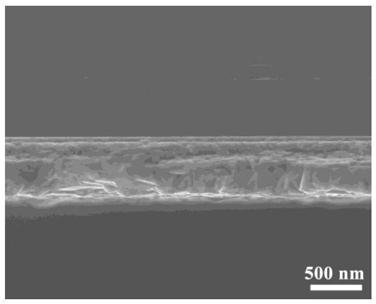

[0046] Weigh 0.1g polyvinylpyrrolidone (PVP) and 0.02g tungsten hexachloride (WCl 6 ) was dissolved in 10 ml of dimethylformamide (DMF), and stirred at room temperature for 1 hour to obtain a spin coating liquid. Spin-coat 20 microliters on the conductive surface of FTO conductive glass at a speed of 2000 rpm, dry at 80°C for 3 hours, and anneal at 500°C in a muffle furnace for 1 hour to form WO 3 film substrate. figure 1 For the obtained WO 3 Scanning electron microscope (SEM) picture of the film substrate, it can be seen that WO 3 The particles are about 50nm and densely covered on the FTO conductive surface. figure 2 For the obtained WO 3 Cross-sectional scanning electron microscopy (SEM) of the film substrate, showing that WO 3 The thickness of the film substrate is about 35 nm.

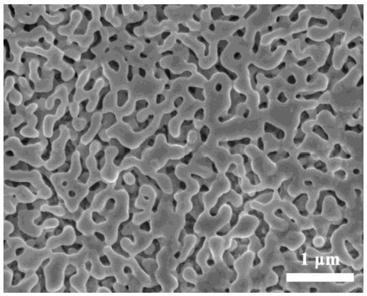

[0047] 0.5g PVP, 2.468g Bi(NO 3 ) 3 ·5H 2 O, 1.337g VO(acac) 2 and 1g DIPA were dissolved in 2gDMF, 3g glacial acetic acid and 1g absolute ethanol, stirred and mixed at room temperatur...

Embodiment 2

[0050] The only difference from Example 1 is that in this example BiVO 4 The spinning time of the layer is 10 minutes, and the other processes are the same as in Example 1, and will not be repeated here. prepared WO 3 / BiVO 4 / FeOOH ternary system composite cross-sectional scanning electron microscope (SEM) such as Figure 9 shown, indicating that BiVO 4 The thickness is 300nm.

Embodiment 3

[0052] The only difference from Example 1 is that in this example BiVO 4 The spinning time of the layer is 20 minutes, and the other processes are the same as in Example 1, and will not be repeated here. prepared WO 3 / BiVO 4 / FeOOH ternary system composite cross-sectional scanning electron microscope (SEM) such as Figure 10 shown, indicating that BiVO 4 The thickness is 1800nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com