Welding wire and welding flux for alternating-current submerged-arc welding of 2.25Cr-1Mo steel

A technology of submerged arc welding and flux, applied in the field of welding technology, can solve problems such as short solidification time, inability to learn from, and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

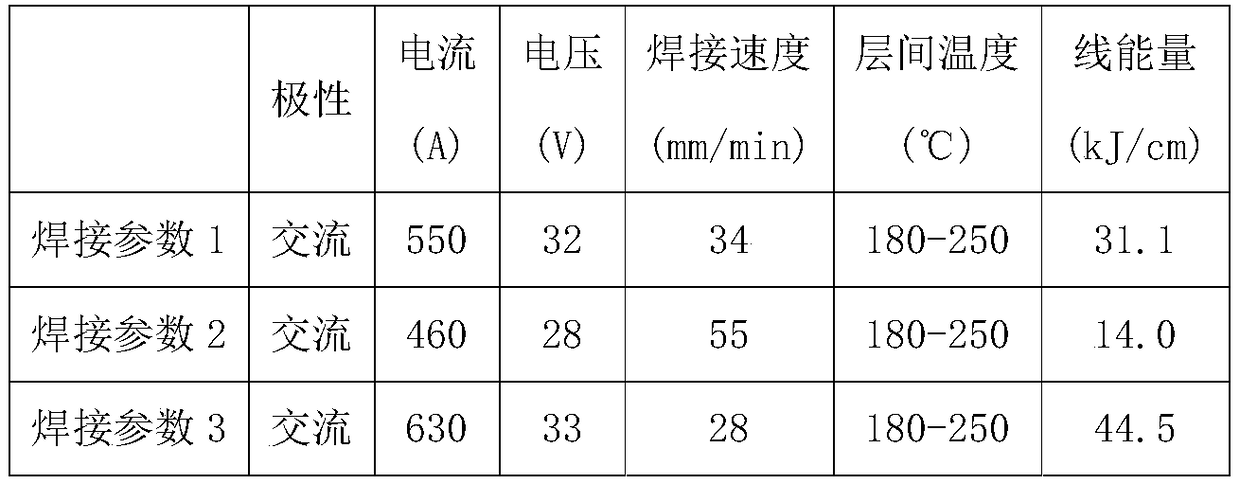

[0066] Preparation of welding wire:

[0067] According to the composition table 1 of the welding wire, the raw materials are processed into Φ4mm submerged arc welding wire after smelting→casting→hot rolling→pickling→cold rolling→drawing→copper plating. In Table 1, No. 1-3 welding wires are welding wires provided by the present invention, and No. 4-6 welding wires are comparison welding wires.

[0068] Table 1: Composition table of No. 1-6 welding wire

[0069]

C

Si

mn

P

S

Cr

Mo

Cu

Ni

Sb

sn

As

Al

O

N

Welding wire 1

0.13

0.19

1.10

0.007

0.004

2.44

1.12

0.08

0.15

0.002

0.001

0.004

0.08

0.005

0.017

Welding wire 2

0.10

0.16

0.85

0.006

0.004

2.37

0.95

0.13

0.11

0.002

0.001

0.004

0.13

0.005

0.027

Welding wire 3

0.09

0.25

1.15

0.005

0.004

2.25

1.00

...

Embodiment 10

[0098] In Example 10, among the components of the welding wire 4 used, C was outside the characteristic range of the welding wire of the present invention. C is the main factor affecting the strength. When C is too high, the C of the deposited metal obtained in the corresponding embodiment 10 is relatively high, and it can be seen from Table 8 that the strength of the weld metal in embodiment 10 has exceeded Due to the high strength of the weld metal, the impact toughness of the weld deposited metal is reduced, and the temper embrittlement resistance test is unqualified.

Embodiment 11

[0099] In Example 11, the Si content in the composition of the welding wire 5 used was relatively high, resulting in an excessively high Si content in the deposited metal. If the Si content is too high, the low temperature impact toughness of the weld metal will be reduced, which is not conducive to the temper embrittlement performance. Among the corresponding weld metal properties in Table 8, the impact toughness decreased below the expected value, and the temper embrittlement resistance test failed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com