Preparation method of swill-cooked dirty oil alcohol acid prepolymer and preparation method of water-based acrylic resin dispersion modified with swill-cooked dirty oil alcohol acid prepolymer

A technology of water-based acrylic acid and waste oil, applied in coating and other directions, can solve the problem of high production cost, and achieve the effect of reducing raw material cost, low raw material cost and improving storability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

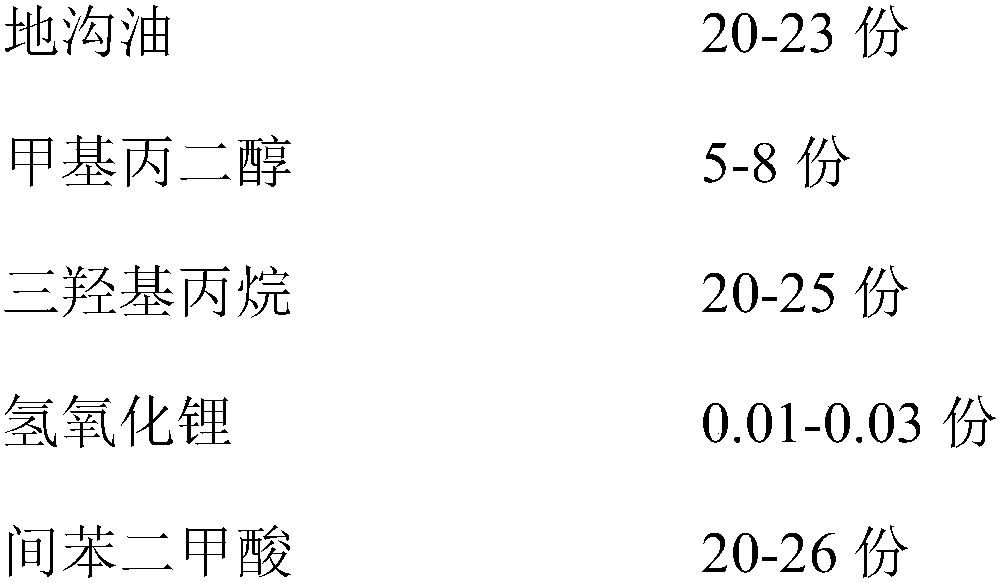

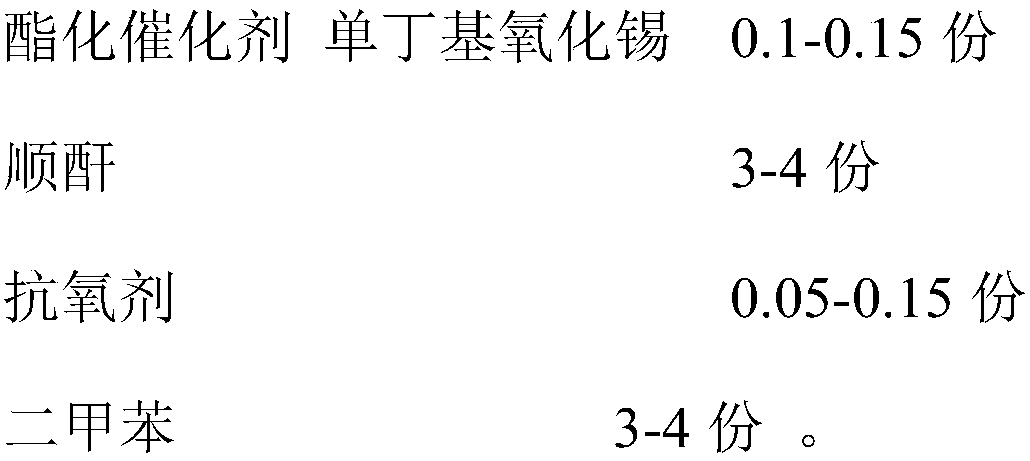

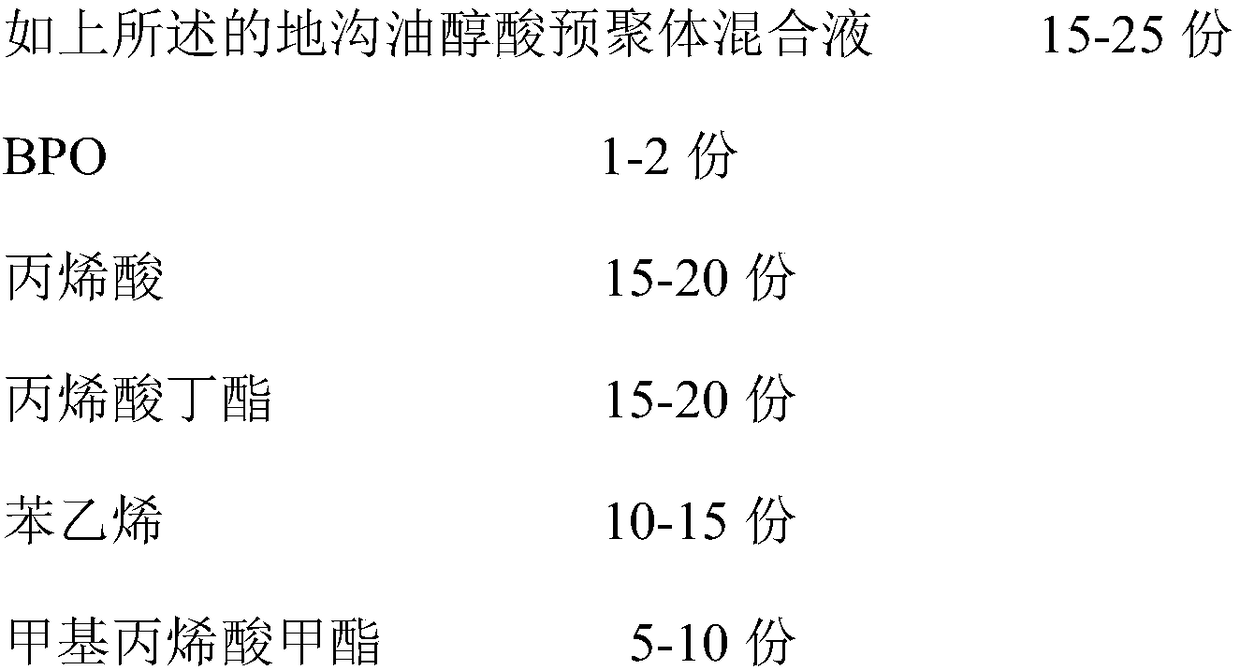

[0041] The raw material formula for preparing waste oil alkyd prepolymer mixture is shown in Table 1-1:

[0042] Table 1-1:

[0043]

[0044]

[0045] The specific steps of preparing waste oil alkyd prepolymer mixed solution by applying the above-mentioned raw material formula are as follows:

[0046] First, put waste oil, methyl propylene glycol, trihydroxypropane, and lithium hydroxide into the reactor, then pass inert gas into the reactor, and heat up to 80°C to start stirring and continue to heat up to 220-225°C. Keep warm at high temperature for 2 hours until the end of alcoholysis.

[0047] Then, the temperature was lowered, and when the temperature dropped to 200° C., the stirring was stopped, and the inert gas was stopped, and the raw materials monobutyltin oxide, isophthalic acid, maleic anhydride, antioxidant and xylene were metered into the following parts by weight, Start stirring, and feed inert gas, then heat up to reflux of xylene, enter the reflux ester...

Embodiment 2

[0057] The raw material formula for preparing waste oil alkyd prepolymer mixture is shown in Table 2-1:

[0058] table 2-1:

[0059] raw material name

Feeding amount, Kg

Specification

460

——

160

Industrial products

Trihydroxypropane

400

Industrial products

0.6

Chemicals

520

Industrial products

Monobutyltin oxide

2

Chemicals

80

Industrial products

3

Chemicals

80

Industrial products

[0060] The specific steps of preparing waste oil alkyd prepolymer mixed solution by applying the above-mentioned raw material formula are as follows:

[0061] First, put waste oil, methyl propylene glycol, trihydroxypropane, and lithium hydroxide into the reaction kettle, then pass inert gas into the reaction kettle, and heat up to 80°C to st...

Embodiment 3

[0071] The raw material formula for preparing waste oil alkyd prepolymer mixture is shown in Table 3-1:

[0072] Table 3-1:

[0073]

[0074]

[0075] The specific steps of preparing waste oil alkyd prepolymer mixed solution by applying the above-mentioned raw material formula are as follows:

[0076] First, put waste oil, methyl propylene glycol, trihydroxypropane, and lithium hydroxide into the reaction kettle, then pass inert gas into the reaction kettle, and heat up to 80°C to start stirring and continue to heat up to 230-235°C. Keep warm at high temperature for 2 hours until the end of alcoholysis.

[0077]Then, the temperature was lowered, and when the temperature dropped to 200° C., the stirring was stopped, and the inert gas was stopped, and the raw materials monobutyltin oxide, isophthalic acid, maleic anhydride, antioxidant and xylene were metered into the following parts by weight, Start stirring, and feed inert gas, then heat up to reflux of xylene, enter t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com