Preparation method of chocolate flavor spice

A chocolate and flavor technology, applied in the preparation of tobacco, essential oils/flavors, fat production, etc., can solve the problems of harsh storage conditions, high cost, and more precipitation, achieve aroma and system stability, enhance aroma intensity, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare pervaporation membranes as follows:

[0026] a. Preparation of casting solution: Take 100g of polydimethylsiloxane and dissolve it in n-hexane, stir well and add 20g of carbon molecular sieve (specific surface area 172.4m 2 g -1 , particle size 5.6μm), ultrasonic dispersion, then add 30g divinylbenzene, 3g dibutyltin dilaurate, continue to stir, after mixing evenly, centrifugal defoaming to make casting liquid; control polydimethylsiloxane in The concentration in the casting solution is 25wt%;

[0027] b. Preparation of pervaporation membrane: Pour the casting solution in step a on the polyvinylidene fluoride base film to scrape the film, dry it at room temperature, and then put it in an oven for cross-linking and aging at 90°C to obtain a separation layer with a thickness of 103 μm pervaporation membrane.

Embodiment 2

[0029] Carry out pervaporation with the pervaporation film of embodiment 1, chocolate flavor spice is prepared as follows:

[0030] (1) Dehydrate and dry distiller's grains to a water content of 3.41wt%, then add 5 times the weight of distiller's grains in water for beating, pasteurize, add 1‰β-primula glucosidase after cooling, enzymatically hydrolyze at 45°C for 4 hours, and filter after enzymatic hydrolysis Obtain the enzymatic hydrolyzate and store it in cold storage;

[0031] (2) Take 40kg of enzymolysis solution and add it to the reaction kettle, add 100g of γ-aminobutyric acid, 100g of L-isoleucine, 120g of L-lysine hydrochloride, 80g of L-tryptophan and 800g of isomaltulose, Reaction at 80°C for 10h;

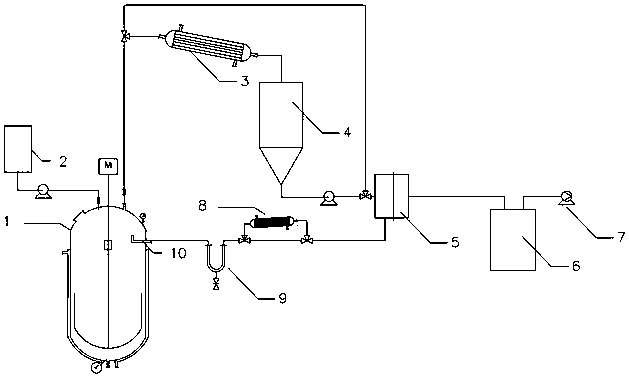

[0032] (3) Turn on the vacuum pump and adjust the three-way control valve to form a circulation loop between the reactor, condenser, buffer tank, pervaporation equipment, U-shaped pipe and return conduit, and increase the reaction temperature until the reaction material...

Embodiment 3

[0036] Carry out pervaporation with the pervaporation film of embodiment 1, chocolate flavor spice is prepared as follows:

[0037] (1) Dehydrate and dry distiller's grains to a water content of 3.41wt%, then add 15 times the weight of distiller's grains in water for beating, pasteurize, add 5‰β-primula glucosidase after cooling, enzymatically hydrolyze at 60°C for 3 hours, and filter after enzymatic hydrolysis Obtain the enzymatic solution and store it in cold storage;

[0038] (2) Take 40kg of enzymolysis solution and add it to the reaction kettle, add 50g of γ-aminobutyric acid, 50g of L-isoleucine, 100g of L-lysine hydrochloride, 90g of L-tryptophan and 400g of isomaltulose, Reaction at 100°C for 2h;

[0039] (3) Turn on the vacuum pump and adjust the three-way control valve to form a circulation loop between the reactor, condenser, buffer tank, pervaporation equipment, U-shaped pipe and return conduit, and increase the reaction temperature until the reaction material in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com